flower border fence roll

-

Creative Strategies for Engaging Storytelling in Your Online Content

The Art of Tongue Twisters A Fun and Challenging Linguistic Adventure Tongue twisters have always fa...

-

decorative outdoor privacy fence

Enhancing Your Garden with Decorative Outdoor Privacy Fences In today’s fast-paced world, creating a...

-

Durable 6-Foot High Chain Link Fence Solutions for Enhanced Security and Property Protection

The Versatility and Benefits of 6% High Chain Link Fence In the world of fencing options, the 6% hig...

-

Affordable Bulk Chicken Wire Available for Purchase Online Now

The Versatility and Benefits of Bulk Chicken Wire for Sale When it comes to poultry farming, gardeni...

-

1% 2 inch welded wire fencing for all your security and containment needs

Welded wire fencing, particularly the 1%-2% inch variety, is a popular choice for homeowners and bus...

-

48 inç tavuk teli ile ilgili benzer bir başlık önerisi

Tavuk Telinin Önemi ve Kullanım Alanları Tavuk teli, özellikle tarım ve inşaat alanında yaygın olara...

-

Công cụ siết chặt hàng rào dây để dễ dàng lắp đặt và điều chỉnh

Công Cụ Kéo Rào Bằng Dây Giải Pháp Đơn Giản và Hiệu Quả Trong thế giới nông nghiệp và chăn nuôi, việ...

-

Creative Designs for 6-Inch Round Fence Post Caps to Enhance Your Outdoor Space

6 inch round fence post caps ....

-

Decorative fence panel for enhancing outdoor privacy

Decorative Screen Panel Fences Enhancing Aesthetics and Privacy in Your Outdoor Space A decorative...

-

Affordable Bulk Welded Wire Fencing for All Your Agricultural and Construction Needs

The Benefits of Wholesale Welded Wire Fencing Welded wire fencing is an essential tool for a variety...

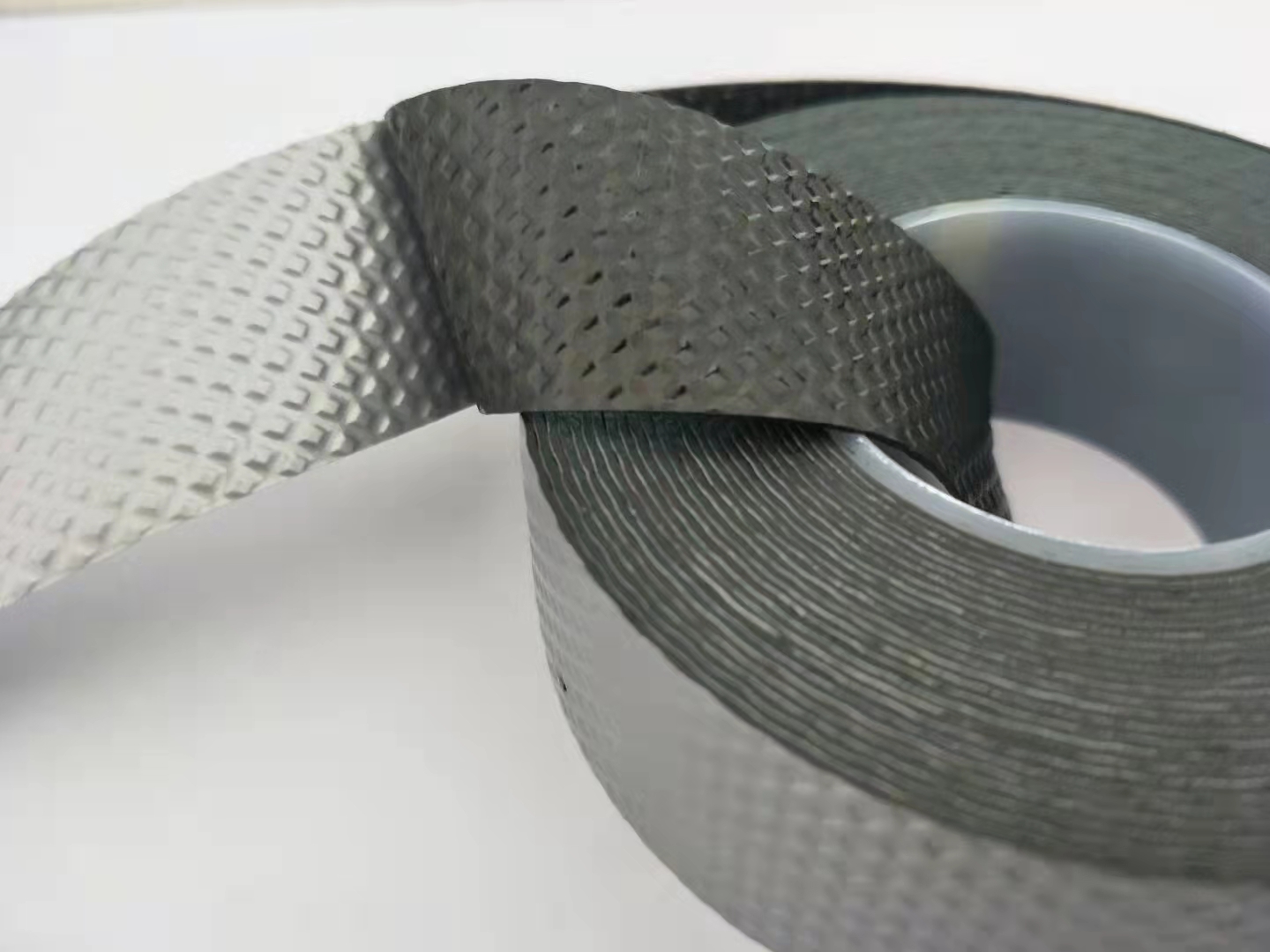

For instance, red tape can be used to highlight promotions or sales, or to create eye-catching displays on the floor For instance, red tape can be used to highlight promotions or sales, or to create eye-catching displays on the floor

For instance, red tape can be used to highlight promotions or sales, or to create eye-catching displays on the floor For instance, red tape can be used to highlight promotions or sales, or to create eye-catching displays on the floor . It eliminates the need for special tools or equipment, making it an ideal choice for quick fixes around the house. From patching up garden hoses to creating temporary weather seals, the tape provides a user-friendly solution that doesn't compromise on strength or longevity.

. It eliminates the need for special tools or equipment, making it an ideal choice for quick fixes around the house. From patching up garden hoses to creating temporary weather seals, the tape provides a user-friendly solution that doesn't compromise on strength or longevity.