Chemical Raising Agents Chemical raising agents, unlike their biological counterparts, work quickly and do not require time for fermentation. The most common chemical leaveners are baking powder and baking soda. Baking soda, or sodium bicarbonate, needs an acidic component (like buttermilk or vinegar) to activate, creating carbon dioxide gas. On the other hand, baking powder contains both an acid and a base and is ready to work when mixed with liquid. There are two types of baking powder single-acting and double-acting. Single-acting baking powder releases gas as soon as it is moistened, while double-acting baking powder does so in two phases—once when wet and again when heated. This characteristic makes double-acting baking powder particularly popular in recipes that require baking in a preheated oven.

One of the primary functions of natural stabilizers is to enhance the texture and mouthfeel of food products. They help to prevent the separation of ingredients, ensuring a uniform consistency. For example, in salad dressings and sauces, stabilizers like xanthan gum and guar gum create a creamy, smooth texture while preventing the oil and vinegar from separating. This not only improves the sensory experience for consumers but also extends the product's shelf life, which is a significant consideration for manufacturers.

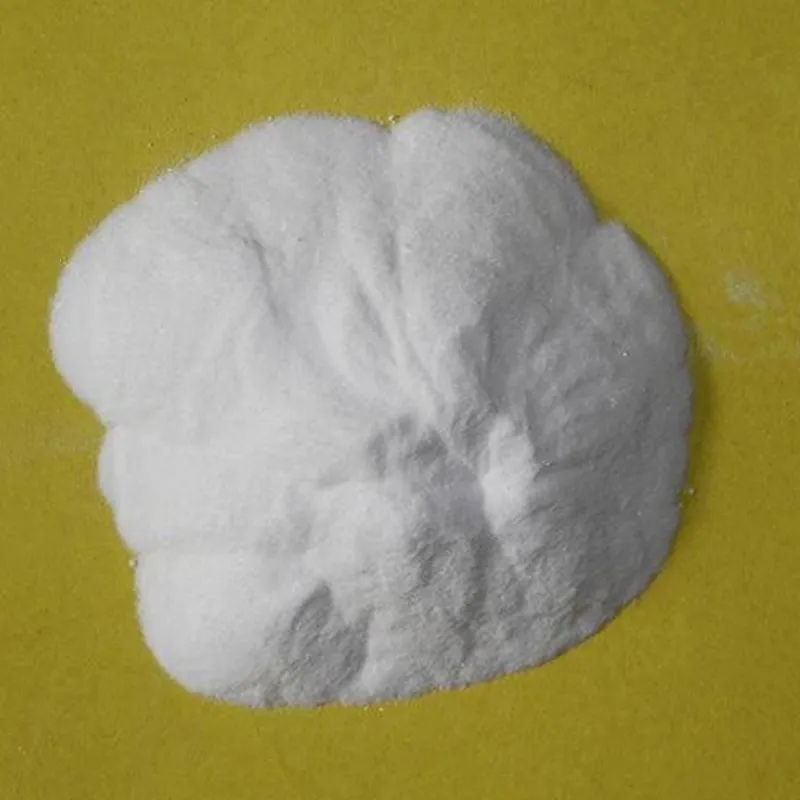

In summary, dried aluminum hydroxide gel is a versatile compound with a wide range of applications across multiple industries. Its properties as an antacid, coagulant, additive in materials science, and ingredient in personal care products highlight its functional diversity. As research continues to uncover new uses and methods for producing high-purity aluminum hydroxide gel, we can expect its significance in sustainable technologies and consumer products to grow even further. The future of this remarkable material is bright, presenting numerous possibilities for innovation and improvement in our everyday lives.

In conclusion, maltodextrin and monosodium glutamate are significant players in modern food formulations. Understanding their properties, benefits, and any associated concerns allows consumers to make informed choices about their dietary intake. As food science progresses, these ingredients will likely continue to evolve, contributing to the diverse and flavorful landscape of contemporary cuisine.

Emulsifiers play a crucial role in the food and cosmetic industries, aiding in the mixing and stabilization of ingredients that typically do not combine well, such as oil and water. One prominent emulsifier is E322, commonly known as lecithin. Derived from various natural sources, including soybeans, sunflower seeds, and egg yolks, E322 offers a range of benefits that have made it a popular choice in various formulations.

Sodium benzoate is a sodium salt of benzoic acid and is widely used as a preservative in food and beverages, as well as in cosmetics and pharmaceuticals. With its ability to inhibit the growth of microbes, sodium benzoate ensures the safety and longevity of products. As demand in various sectors increases, the role of sodium benzoate suppliers becomes increasingly vital. This article explores the market for sodium benzoate, the importance of reliable suppliers, and key factors to consider when selecting a supplier.

. For example, in baked goods, these emulsifiers can improve moisture retention and soft texture, which are highly desirable traits for consumers. They can also influence the sensory attributes of food products, making them creamier or lighter, depending on the intended outcome. This ability to modify texture and flavor profiles is particularly valuable in a market where consumer preferences are constantly evolving.

Beetroot red is employed extensively in the food industry, particularly in the coloring of beverages, confectioneries, dairy products, and baked goods. It is commonly used in products like jams, jellies, sauces, and yogurt, imparting an appealing color that enhances the overall aesthetic of foods. E162 is also valued for its stability, as it can withstand various pH levels and temperatures, making it suitable for a wide range of culinary applications.

Applying nitrogen fertilizers requires careful consideration to maximize their effectiveness while minimizing environmental harm. Common application methods include broadcasting, banding, and fertigation. Broadcasting involves spreading fertilizers evenly over the soil surface, while banding places fertilizers in concentrated bands near plant roots. Fertigation, which involves incorporating fertilizers into irrigation systems, allows for precise control over nutrient delivery.

Citric acid, sorbic acid, lactic acid, benzoic acid, propionic acid — These work to preserve food by making food and drink more acidic, and thus hostile for unwanted organisms. All can be sourced from either plants or human-made and are widely viewed as safe, though benzoic acid may cause allergic reactions in some.