The thickness of steel grating also plays a critical role in its applications. Typically, thickness ranges from 1/2 inch to 1 inch, with heavier grating often used in high-traffic areas or environments subject to heavy loads. For example, a 1-inch thick grating is ideal for industrial operations, where forklifts and trucks are common, while a 1/2 inch thick option may be sufficient for pedestrian walkways.

In the field of optical engineering, the term grating refers to a structure with a periodic pattern that disperses light into its constituent wavelengths. Among the various types of gratings, the 19w2% grating represents a specific configuration that plays a vital role in various applications, including spectroscopy, telecommunications, and laser systems. Understanding the characteristics and implications of this grating type is important for both novices and professionals in optics.

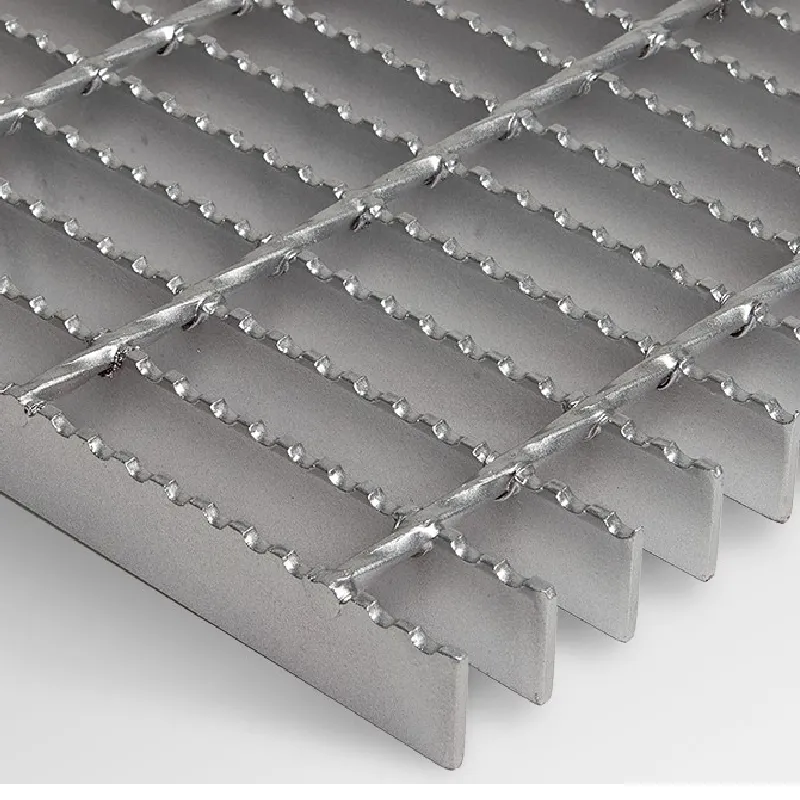

Steel gratings come in various types, including welded, swaged, and pressure-locked. Each type has unique features suitable for specific applications. For instance, welded steel gratings are robust and suitable for heavy-duty uses, whereas swaged grating allows for lightweight constructions without compromising strength.

Derudover påvirker tykkelsen også ristenes modstandsdygtighed over for korrosion og slid. Et tykkere materiale er generelt mere robust og har en længere levetid, især i miljøer, hvor det udsættes for fugt, kemikalier eller ekstreme temperaturer. Dette er især vigtigt i maritime omgivelser, hvor stål ofte kommer i kontakt med saltvand, der kan forårsage hurtigere nedbrydning af materialet.

Сеюм, нархҳо метавонанд дар кишварҳои гуногун таъриф шаванд. Масалан, панелҳои фолад дар кишварҳои рушди шод метавонанд арзонтар бошанд, дар ҳоле ки дар кишварҳои пешрафта нархҳо бештар буда метавонанд, чунки талабот ва сифати маҳсулот бештар мебошад. Пайвастагиҳои логистикии низонарс пахш ва пешераву нархҳоро низ ба дараҷаи хусусиятҳои маҳаллии боунт кунанда, дар нисбати нархи панелҳои фолад таъсир мерасонад.

The weight of bar grating can vary significantly depending on several factors, including the material used, the thickness of the individual bars, and the spacing between them. Common materials for bar grating include steel, aluminum, and fiberglass. Steel grating is known for its strength and durability, making it suitable for heavy-duty applications. It typically weighs around 3 to 5 pounds per square foot, depending on its specific design and dimensions. Aluminum grating, on the other hand, offers a lighter alternative, usually weighing about 2 to 4 pounds per square foot. This makes aluminum bar grating an excellent choice for projects where weight reduction is essential.

Sammenfattende tilbyder stålristgulve en række fordele, herunder styrke, sikkerhed, holdbarhed og bæredygtighed. Deres alsidighed gør dem til en fremragende valg for enhver, der ønsker et pålideligt og effektivt gulv, der kan stå imod tidens tand og de udfordringer, der følger med forskellige arbejdspladser. Med stålristgulve får man ikke bare et gulv, men en langvarig investering i kvalitet og sikkerhed.

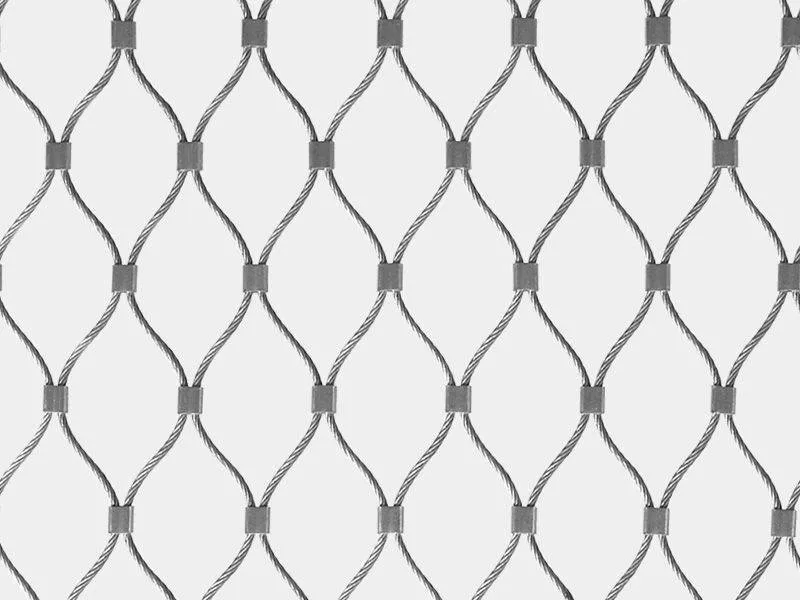

In addition to its functional benefits, stainless steel bar grating can also contribute to the aesthetic appeal of a facility. The sleek, modern look of stainless steel provides a professional appearance, enhancing the overall ambience of a space. It can be seamlessly integrated into various architectural designs, making it a popular choice for walkways, balconies, and even artistic installations.