Ceiling access panels are generally small, removable sections of ceiling that provide convenient access to spaces above. They come in various materials, sizes, and styles, and can be made of plastic, metal, or drywall. The right access panel not only allows for maintenance but also helps maintain the aesthetic of your home. When installed properly, these panels blend in seamlessly with the surrounding ceiling.

In conclusion, external waterproof access panels offer numerous benefits, making them an invaluable addition to any building project. Their waterproof integrity, ease of access, design versatility, enhanced safety features, and long-term cost-effectiveness make them essential for maintaining and protecting critical systems. As technology and building materials continue to evolve, the role of these access panels is only set to expand, ensuring that they remain a staple in modern construction and facility management.

One of the most prominent advantages of PVC gypsum ceilings is their aesthetic versatility. Available in a variety of colors, patterns, and textures, PVC gypsum ceilings can complement any interior design style, from contemporary to traditional. The smooth finish of the PVC surface allows for vibrant and eye-catching designs, providing homeowners and designers with the flexibility to create visually striking compositions.

Durability is another essential factor when considering ceiling T-bar brackets. Made from robust materials such as steel or aluminum, they are designed to withstand the test of time. Moreover, because they facilitate easy access to above-ceiling systems, maintenance becomes a straightforward process. Should an issue arise with plumbing or electrical fixtures, the suspended ceiling can be opened without the need for extensive demolition, saving time and money.

In conclusion, waterproof access panels are essential components in the architecture and maintenance of modern facilities. Their ability to provide secure, moisture-resistant access to critical systems not only enhances operational efficiency but also protects valuable infrastructure. As building standards continue to evolve, the importance of incorporating waterproof access panels into construction and renovation projects will only increase. Whether in residential, commercial, or industrial settings, these panels offer a practical solution that combines functionality with aesthetic appeal, ensuring that both maintenance staff and building occupants are satisfied.

Micore 300 is a type of mineral fiber board primarily composed of high-temperature mineral fibers, which are bound together using a non-combustible bonding agent. This composition gives Micore 300 its distinctive features, including excellent thermal insulation, sound attenuation, and fire resistance. The board is engineered to meet rigorous building codes and standards, making it suitable for various applications across different sectors.

Installation of acoustical ceiling grids is relatively straightforward, which contributes to their growing popularity. Lightweight materials and modular designs allow for a quick setup, facilitating renovations and new constructions alike. Furthermore, these ceilings can be designed to accommodate lighting fixtures, HVAC systems, and other utilities, ensuring that functionality remains a top priority without sacrificing aesthetics.

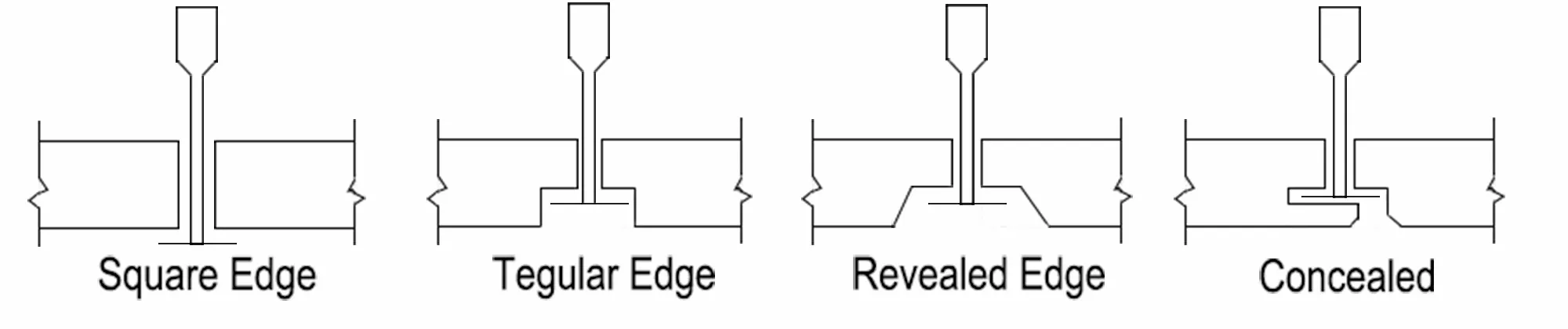

The choice of ceiling material is a critical decision for designers, architects, and builders, as it significantly influences the aesthetics and functionality of a space. In recent years, grid ceiling systems, often referred to as suspended ceilings or drop ceilings, have gained immense popularity due to their versatility, ease of installation, and potential for acoustic improvement. However, understanding the factors that affect the pricing of grid ceiling materials is essential for making informed decisions in construction and renovation projects.

Installing a cross tee ceiling requires careful planning and execution. It begins with marking a grid on the ceiling, ensuring that it is square and level. Next, main tees are secured to the main structure, followed by the installation of cross tees at designated intervals, typically set at 2 feet apart. Finally, ceiling tiles are inserted into the grid, securing them in place.