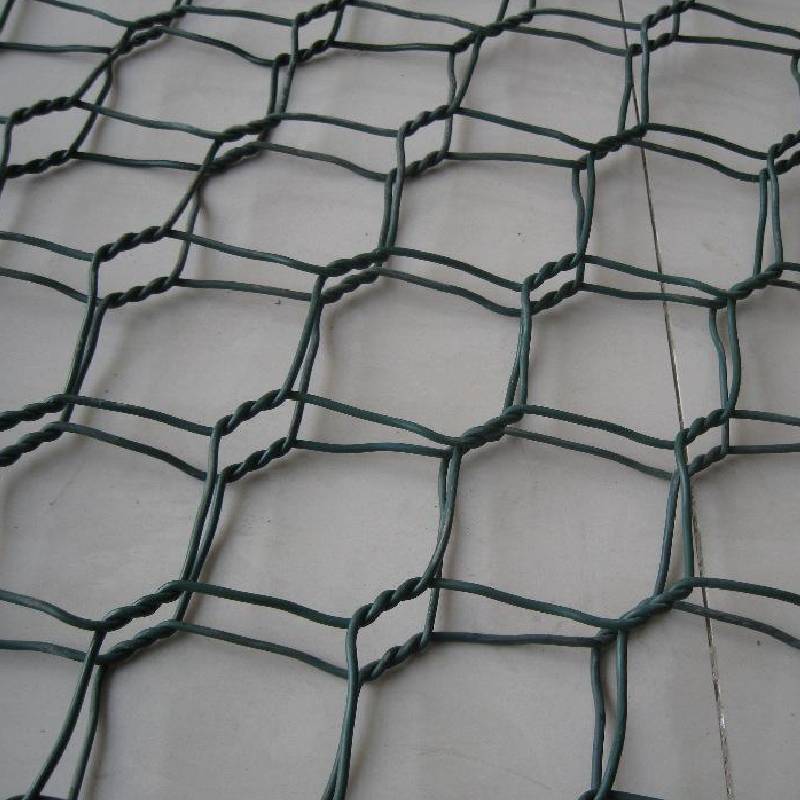

Reinforcement wire mesh panels are widely used in various construction projects, including residential buildings, commercial structures, pavements, and more. In slabs, for instance, they are often placed directly within the concrete to enhance strength. In situations where thin concrete sections are required, such as in driveways or sidewalks, wire mesh adds the necessary support without significantly increasing weight or thickness.

Additionally, welded mesh is corrosion-resistant, especially when made from galvanized or stainless steel materials. This resistance to rust and weathering allows it to maintain its integrity and appearance over time, making it suitable for both indoor and outdoor applications. Moreover, its ease of installation saves time and labor costs, making welded mesh a cost-effective solution.

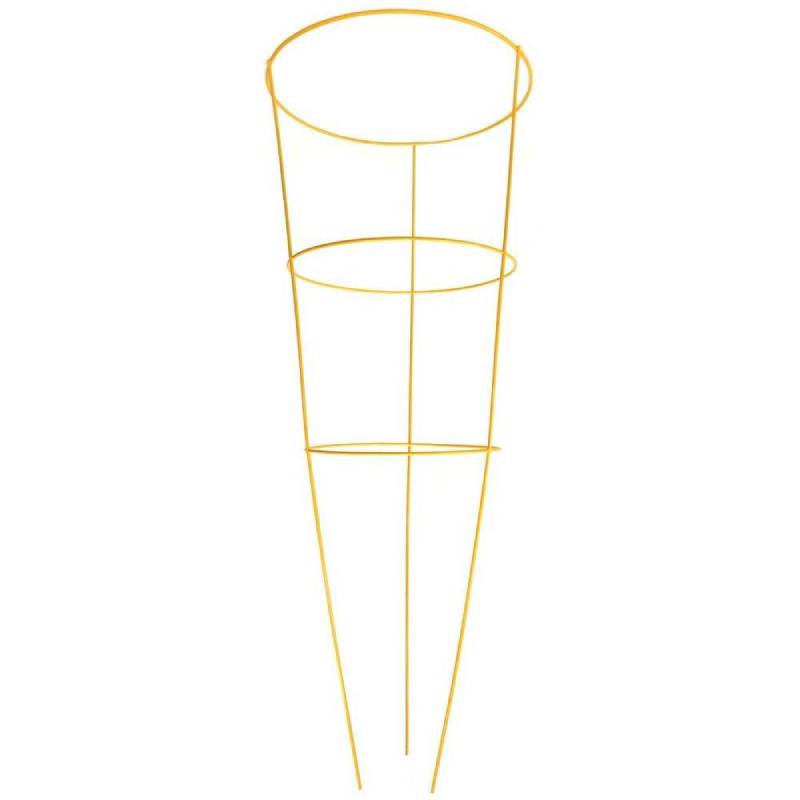

One of the primary attractions of grid walls is their ability to serve as an adaptable foundation for various applications. In home decor, grid walls can transform a bland wall into a focal point. By allowing users to hang artwork, photographs, or decorative items, they provide a customizable canvas that can be easily updated to reflect personal style or seasonal themes. The modular nature of grid walls means that elements can be rearranged or swapped out without the need for significant renovations, offering a level of flexibility that traditional display methods often lack.

Concrete reinforcing mesh, often referred to as welded wire mesh, consists of a grid made from steel wires, which are welded at their intersections. This mesh is integrated into concrete to provide tensile strength that counteracts the natural brittleness of concrete. The use of reinforcing mesh is particularly prevalent in slabs, pavements, and walls, where the structure is subjected to various loads and stresses. The incorporation of this mesh helps in preventing cracks and extending the lifespan of the concrete structures.

As of late 2023, the stainless steel mesh market has been witnessing notable trends. The ongoing expansion of the construction industry in emerging economies has increased the demand for high-quality stainless steel mesh for various applications, including filtration and architectural uses. Additionally, the rising awareness of hygiene standards, particularly in the food and pharmaceutical industries, has bolstered demand for corrosion-resistant materials.

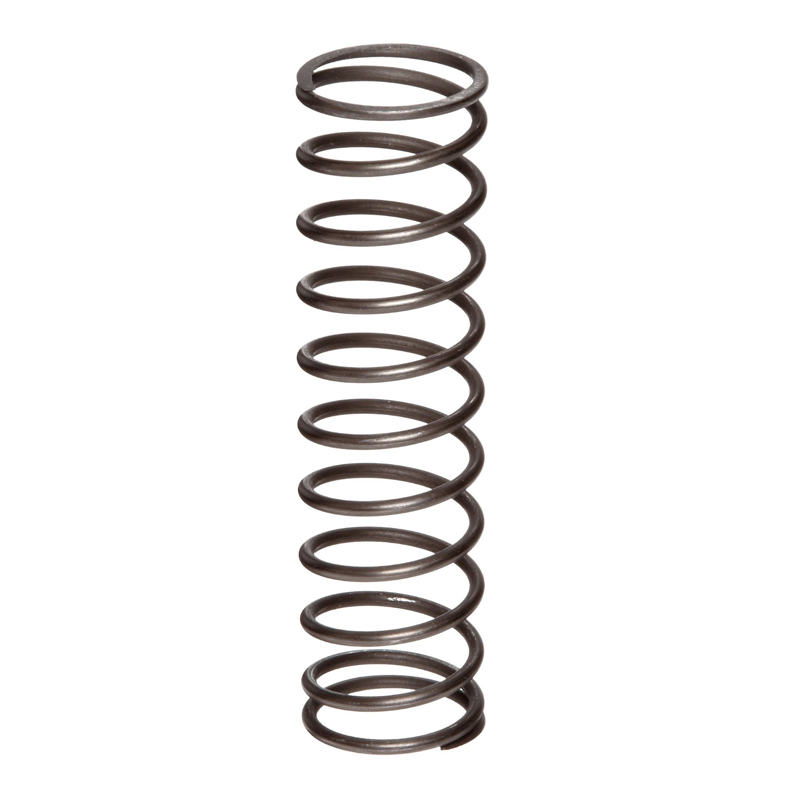

In summary, flat coil torsion springs are an essential component in countless applications across various industries due to their unique design and functional capabilities. Their ability to store and release energy through controlled torsion makes them invaluable in automotive, consumer electronics, and industrial applications. As technology continues to evolve and products become increasingly compact and efficient, the demand for flat coil torsion springs is likely to grow, underscoring their significance in modern engineering and design. Understanding the principles and advantages of these springs is crucial for engineers and designers looking to innovate and optimize their products.

In summary, the extended hook spring is a vital component of mechanical design, playing an essential role in various applications across different industries. Its unique design, ability to store and release energy effectively, and adaptability to specific requirements make it a favorite among engineers and designers. As technology progresses and the demands of mechanical systems evolve, the extended hook spring will undoubtedly continue to be an important element, contributing to innovations that enhance functionality and efficiency in countless applications. Whether it's in a simple household tool or a sophisticated machine, the impact of this unassuming spring is profound and far-reaching.