Hydroxyethyl cellulose is a versatile and valuable compound with a wide range of applications across various industries, including pharmaceuticals, cosmetics, food, construction, and agriculture. Its unique chemical properties, combined with its biocompatibility and non-toxic nature, make it an essential ingredient in many formulations. As research continues and new applications are discovered, hydroxyethyl cellulose is poised to maintain its significance in both existing and emerging markets. Understanding and utilizing this polymer can provide solutions to enhance product performance and sustainability in a variety of fields.

HPMC density refers to the mass per unit volume of this polymer, which can vary based on the degree of substitution and moisture content. Generally, the density of HPMC is influenced by its molecular weight and viscosity. In pharmaceutical formulations, the density of HPMC is of particular interest because it affects the flow properties of powders, compaction characteristics, and ultimately, the release profile of the active pharmaceutical ingredient (API).

In conclusion, the solubility of HPMC in cold water is a property that underpins its utility across numerous applications. Factors such as the degree of substitution, molecular weight, temperature, and dispersion methods all play critical roles in determining how effectively HPMC can be utilized in various formulations. As research continues to explore the functional versatility of HPMC, its importance in modern industry remains undeniably significant.

HEC possesses several unique properties that make it an attractive ingredient in various formulations. One of its most notable features is its ability to form gels and thickened solutions, which are desirable in both cosmetic and pharmaceutical products. In cosmetics, HEC is often used as a thickener, stabilizer, and emulsifier in creams, lotions, and gels. Its capacity to retain moisture makes it particularly beneficial in skin-care products, helping to keep the skin hydrated and improving the overall texture of formulations.

As a derivative of natural cellulose, MHEC is generally considered safe for use in various applications, including food and cosmetics. It is non-toxic, biodegradable, and environmentally friendly, making it a preferred choice among manufacturers aiming to reduce their ecological footprint. However, as with any chemical substance, proper handling and usage guidelines must be followed to ensure safety and efficacy.

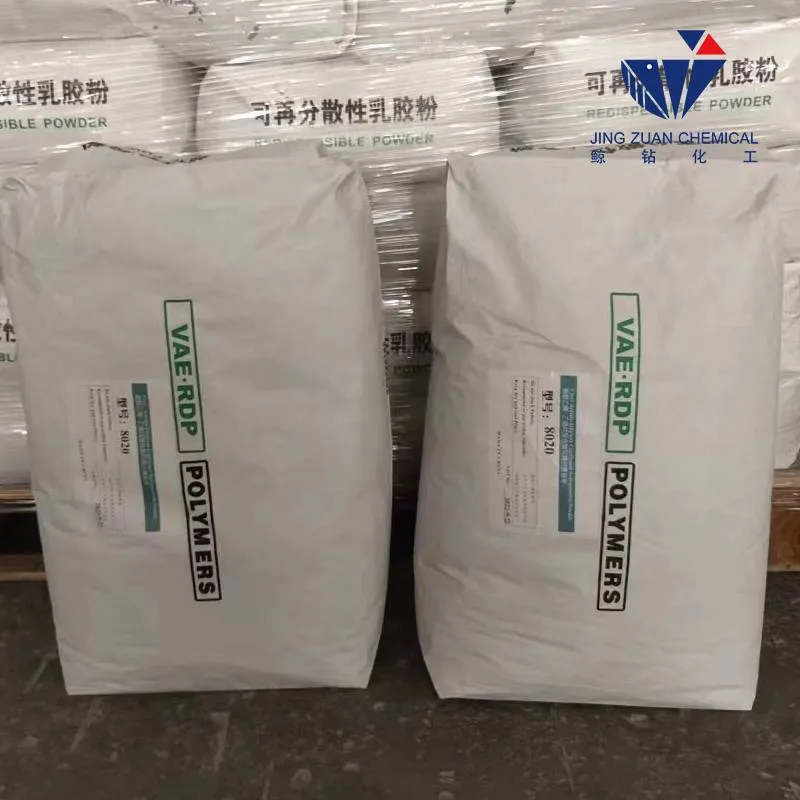

1. Raw Material Costs The cost of raw materials, primarily the polymers used to manufacture RDPs, plays a crucial role in determining the final price. Fluctuations in the price of petrochemicals, such as ethylene and propylene, affect the production costs of these polymers. Additionally, any changes in supply chains or availability of these raw materials can lead to price volatility.

HPMC is favored in many applications due to its non-toxic nature, high viscosity, and ability to form films. The solubility of HPMC in ethanol can vary based on several factors, including its molecular weight and the degree of substitution, which refers to the amount of hydroxypropyl and methoxy groups present in its structure. Generally, HPMC is soluble in polar solvents, but its solubility in ethanol is more nuanced as ethanol is a semi-polar solvent.

Beyond construction and coatings, redispersible powder finds usage in various other fields, including personal care products, pharmaceuticals, and food processing. In personal care, it improves the stability and consistency of creams and lotions, ensuring even application and long-lasting effects. In food processing, the powder can help in the encapsulation of flavorings and nutrients, enabling controlled release during consumption.

As industries continue to leverage the power of high-performance computing, the importance of HPMC safety cannot be overstated. It is crucial for organizations to implement comprehensive safety measures that encompass both physical and cybersecurity aspects. By prioritizing safety, companies can protect their valuable assets, maintain operational continuity, and foster a secure computing environment conducive to innovation and discovery. As technology evolves, so too must our approaches to ensuring safety within these powerful HPC systems.

In conclusion, HPMC manufacturers are fundamental contributors to the pharmaceutical and construction industries, supplying a vital product that enhances the performance and quality of a wide range of applications. As the demand for HPMC continues to grow, driven by advancements in technology and increasing awareness of sustainability, these manufacturers will play an increasingly important role in meeting market needs. With a focus on innovation, quality, and sustainability, HPMC manufacturers are well-positioned to thrive in a competitive global marketplace. The ongoing developments in this sector promise exciting advancements that will impact various industries positively, making HPMC a compound to watch in the years to come.

1. Viscosity Grades HPMC is typically available in different viscosity grades, which are crucial for determining the thickness of the final product. The viscosity is often measured in centipoise (cP) at specified concentrations. For instance, low viscosity grades like HPMC E3 provide solutions that are more mobile, making them ideal for products that require lower viscosity, such as certain coatings and adhesives. On the contrary, high viscosity grades, like HPMC E50, are employed in formulations needing a thicker consistency, such as in gel formulations or in certain types of food products.