Different types of field fence panels are available, including woven wire, barbed wire, and electric fencing. Each type serves a specific purpose; for example, woven wire is often used for sheep and goats, as it provides an adequate barrier while minimizing the risk of injury. Conversely, electric fencing is commonly employed for more aggressive livestock like cattle, as the unpleasant shock deters them from attempting to breach the enclosure.

In conclusion, temporary cattle fences are an indispensable asset in contemporary agriculture. Their flexibility, efficiency, and cost-effectiveness make them an ideal choice for managing grazing practices, protecting crops, and enhancing the overall welfare of livestock. As farmers continue to seek innovative solutions to meet the challenges of modern farming, temporary cattle fences will undoubtedly play a vital role in promoting sustainable and productive agricultural practices. The seamless integration of this technology into the daily operations of farms can lead to improved outcomes for both the land and the livestock, ultimately contributing to the resilience and sustainability of the agricultural sector as a whole.

Field fencing is an essential component for many agricultural and rural properties. Whether you are looking to contain livestock, protect crops, or enhance the aesthetic appeal of your land, investing in quality fencing is crucial. However, one of the primary considerations for property owners is the cost associated with installing and maintaining these fences. In this article, we will explore various factors that influence field fencing prices and provide insights to help prospective buyers make informed decisions.

Moreover, the materials used in temporary cattle fencing have evolved, contributing to its popularity among farmers. Today, options such as portable electric fences, high-tensile wire, and plastic fence posts provide durability and effectiveness. Electric fencing, in particular, is a preferred choice due to its ability to establish a secure boundary without the need for traditional posts and heavy materials. This method not only reduces labor costs but also minimizes damage to the landscape, as electric wires can be easily repositioned with minimal disruption.

In summary, wire mesh has become an indispensable and important material in modern society due to its diverse applications and wide range of fields. Whether in the fields of construction, filtration, agriculture, or industry, wire mesh provides strong support for the development of various industries with its excellent performance and reliability.

In conclusion, hefty die springs are an indispensable component in various industries, providing strength, reliability, and adaptability. Their applications span from manufacturing and automotive sectors to custom machinery solutions, proving their versatility and importance. As technology advances and demands increase, the role of hefty die springs will undoubtedly continue to evolve, supporting the innovations of tomorrow while ensuring the efficiency and safety of today’s industrial operations.

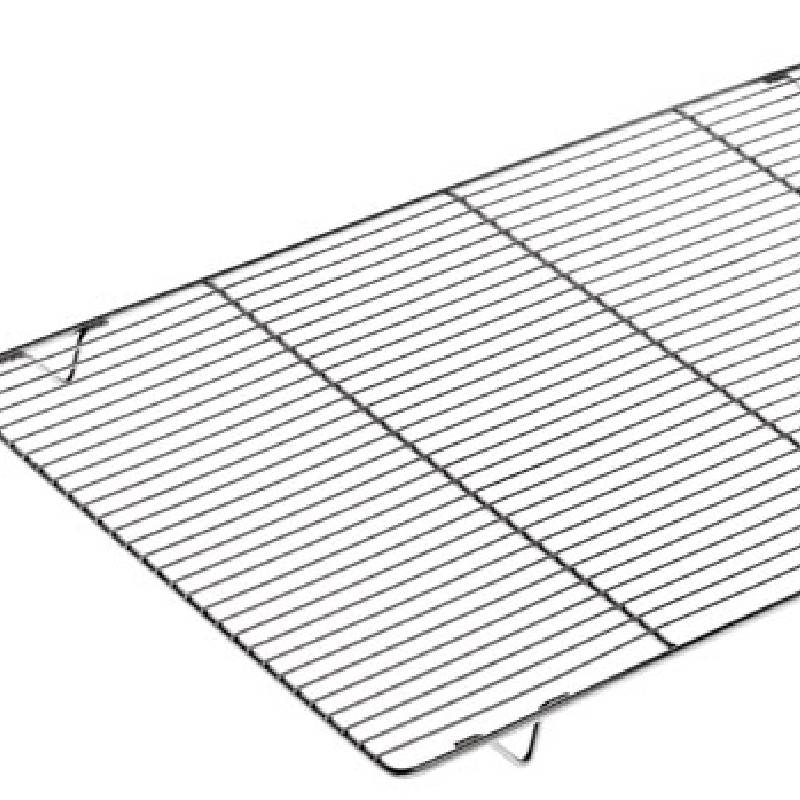

In terms of functionality, these wire mesh panels are incredibly versatile. They can be used for a wide range of applications, including security fencing, pet enclosures, trellises for climbing plants, and as safety barriers in commercial facilities. Their sturdy construction makes them ideal for high-traffic areas where safety is a priority. Moreover, the mesh design allows for visibility while providing a secure barrier, making them a preferred choice for playgrounds and public spaces.

When it comes to industrial and construction applications, choosing the right type of wire is crucial for ensuring structural integrity and durability. One of the popular choices in this regard is the 10% gauge galvanized steel wire. But what exactly does this mean, and why is it so widely used? In this article, we will explore the properties, benefits, and applications of 10% gauge galvanized steel wire.

Moreover, wire ties facilitate the integration of insulation and other materials within the wall cavity. This is increasingly important in modern construction, where energy efficiency and thermal performance are paramount. Insulated cavity walls, supported by wire ties, not only provide thermal resistance but also enhance the overall longevity of the building, as they protect against moisture infiltration that can lead to deterioration over time.