In cosmetics, HPMC is valued for its thickening and film-forming properties. It is used in various formulations, including creams, lotions, and gels, to enhance viscosity and stability. Its non-irritating nature makes it suitable for sensitive skin products, providing a protective barrier that helps retain moisture and improve skin texture.

At its core, redispersible emulsion powder consists of synthetic polymers, typically derived from materials such as vinyl acetate, ethylene, and acrylates. These polymers provide unique properties that enhance the performance of products in which they are incorporated. Notably, REP boasts excellent water resistance, thermal stability, and flexibility, allowing for high-performance formulations that can withstand varying environmental conditions.

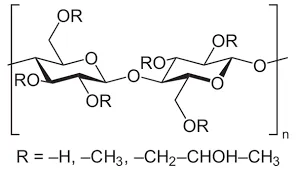

Propyl Methyl Cellulose (PMC) is a derivative of cellulose, a natural polymer that forms the structural component of plants. This modified cellulose has gained significant attention in various industries due to its unique properties and versatility. In this article, we will explore the characteristics, applications, and significance of Propyl Methyl Cellulose, emphasizing why it is an essential ingredient in pharmaceuticals, food, construction, and personal care products.

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used cellulose derivative that has found applications in various industries, particularly in construction and pharmaceuticals. HPMC is a crucial ingredient in many products, owing to its unique properties such as water retention, emulsification, and film-forming capabilities. As the demand for HPMC has surged in recent years, manufacturers have stepped up to meet this growing need. This article explores the role of HPMC manufacturers and their impact on different sectors.

Redispersible polymer powders (RDPs) play a crucial role in various industries, particularly in construction, coatings, and adhesives. These specialized powders, which become re-dispersed in water, offer unique properties that enhance the performance of construction materials, making them indispensable in modern formulations.

3. Cosmetics and Personal Care HPMC is an important ingredient in the cosmetics industry, utilized in formulations for lotions, creams, and hair care products. Its emulsifying properties aid in the uniform distribution of ingredients, while its thickening abilities enhance the product’s texture. Additionally, HPMC helps improve the stability of products, ensuring they maintain their efficacy over time.

HPMC powder, with its multifaceted applications, plays a pivotal role in the Chinese market across various industries. As trends towards sustainability and health consciousness continue to grow, the relevance of HPMC is likely to increase. Its versatility makes it an indispensable ingredient in formulations that meet modern consumer expectations, and its continued evolution will undoubtedly influence its market dynamics in China and beyond. With ongoing research and development, the future of HPMC powder looks promising, poised to meet the ever-evolving demands of various industries.

The global HPMC market has been experiencing substantial growth, driven by increasing demand in the pharmaceutical sector, particularly in the formulation of drug delivery systems. HPMC is favored in the industry for its excellent rheological properties and ability to act as a binder, film-former, and thickener. As the pharmaceutical sector expands, particularly with the rise of generics and biosimilars, companies producing HPMC are likely to see a corresponding increase in stock value.

Hydroxypropyl methylcellulose (HPMC) powder is a versatile cellulose ether derived from natural cellulose sources. It plays a crucial role in various industries, including pharmaceuticals, food, construction, and cosmetics. This article aims to provide an insightful overview of HPMC powder, emphasizing its properties, applications, and benefits.

When combined, HPMC and SDS exhibit an intriguing synergy that enhances their individual characteristics. The interaction between HPMC and SDS can lead to improved viscosity and stability in formulations. For example, in the pharmaceutical industry, the combination of HPMC and SDS is often used to formulate drug delivery systems. The viscosity-enhancing properties of HPMC can help control the release rate of active pharmaceutical ingredients, while SDS aids in drug solubility, ensuring better bioavailability.