In recent years, LED neon strip lights have gained popularity for their versatility, energy efficiency, and striking appearance. These innovative lighting solutions are ideal for enhancing the aesthetic of any space, whether it's a cozy home, a vibrant retail store, or an exciting event venue. As we delve into the world of LED neon strip lights, we'll explore their benefits, applications, and tips for choosing the best options for your needs.

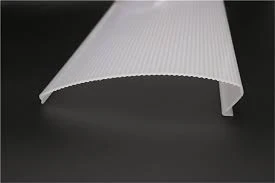

Silicone sealing strips are flexible strips made from high-grade silicone rubber, designed to fill gaps and create an airtight and watertight seal. Their flexibility allows them to conform to various surfaces, ensuring a snug fit that minimizes the risk of air, water, or dust infiltration. These sealing strips are often used in doors and windows, automotive applications, kitchen appliances, and electronic devices, among other uses.

Good suppliers will offer a wide range of products, catering to different door and window types, as well as varying insulation needs. They should also provide options that differ in material, thickness, and design, allowing consumers to choose the best fit for their specific requirements. Suppliers that understand market demands and trends also tend to stay ahead, moving towards more sustainable materials and practices, which appeal to environmentally conscious consumers.

In conclusion, LED neon light stand factories are pivotal in shaping the future of lighting solutions. Their ability to produce high-quality, customizable, and innovative products caters to a growing market that values aesthetics and efficiency. As these factories continue to evolve, they not only enhance the lighting landscape but also contribute positively to local economies and environmental sustainability. With the ongoing advancements in technology and design, the future looks bright for LED neon light stands and their manufacturers, promising exciting developments in the realm of lighting.

Square rubber seal strips are typically made from materials such as silicone, EPDM (Ethylene Propylene Diene Monomer), or neoprene. These materials are chosen for their durability, flexibility, and resistance to various environmental factors, such as extreme temperatures, moisture, and chemicals. The square shape of these strips allows for a secure fit within grooves or channels, ensuring a tight seal that minimizes leakage and enhances insulation.

These strips are used extensively in the automotive industry to seal windows, doors, and sunroofs, effectively preventing water and air leakage. In construction, butyl sealing strips are vital for roofing membranes and facades, ensuring buildings remain watertight and energy-efficient. Additionally, packaging industries utilize these strips to enhance product integrity and shelf-life by creating airtight seals.

The proliferation of butyl sealing strip factories also has significant economic implications. These factories create jobs in manufacturing, research and development, and quality assurance, contributing to local and national economies. Furthermore, as industries increasingly recognize the importance of sustainable practices, many factories are adopting eco-friendly production methods. Decreasing waste, recycling materials, and utilizing renewable energy sources are becoming common practices in the industry.

In summary, the pricing of automatic lifting sealing strips is influenced by various factors, including material quality, size, production volume, technology features, supplier reputation, and market demand. As businesses assess their packaging needs, it is vital to consider both the costs and the potential value that high-quality sealing strips can provide. By making informed decisions, companies can enhance their packaging processes while maintaining competitive pricing, ultimately leading to improved efficiency and profitability in their operations. As the market continues to evolve, staying informed about price changes and industry trends will be crucial for businesses looking to optimize their use of automatic lifting sealing strips.

Looking ahead, the door seal strip market is poised for evolution. With advancements in technology, manufacturers are investing in innovative materials and designs that offer superior performance and longevity. Additionally, the integration of smart technologies into building materials, including seals, is on the rise, providing potential for new product developments. Exporters must remain adaptable to these trends, ensuring they offer the latest products to meet evolving customer needs.