In summary, redispersible powder polymers are a crucial component across multiple industries, particularly in construction and adhesives. Their key benefits, such as improved adhesion, flexibility, and water resistance, make them indispensable for enhancing material performance. As innovation continues, these polymers will likely evolve to meet new application demands and environmental standards, solidifying their role in both traditional and sustainable practices. Whether used in high-performance building materials or eco-friendly adhesives, their versatility cannot be overstated.

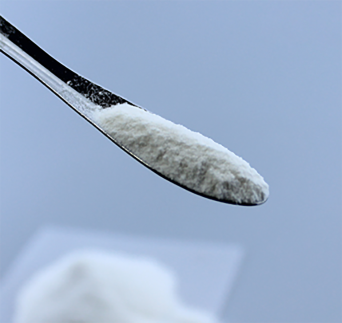

Mortar adhesive additives are chemical substances mixed into traditional mortar formulations to improve their physical and chemical properties. These additives can vary widely, ranging from polymers and fibers to mineral enhancers. Their purpose is to modify the mortar's characteristics, such as adhesion, flexibility, workability, water resistance, and setting time, which ultimately contribute to the longevity and durability of the finished structure.

Hydroxypropyl Methylcellulose (HPMC) has emerged as a crucial additive in the formulation of wall putty, a material used to create a smooth surface on walls before painting or finishing. Wall putty serves both aesthetic and functional purposes, ensuring that surfaces are uniform, durable, and free from imperfections. By incorporating HPMC into wall putty formulations, manufacturers can significantly enhance the performance and quality of their products.

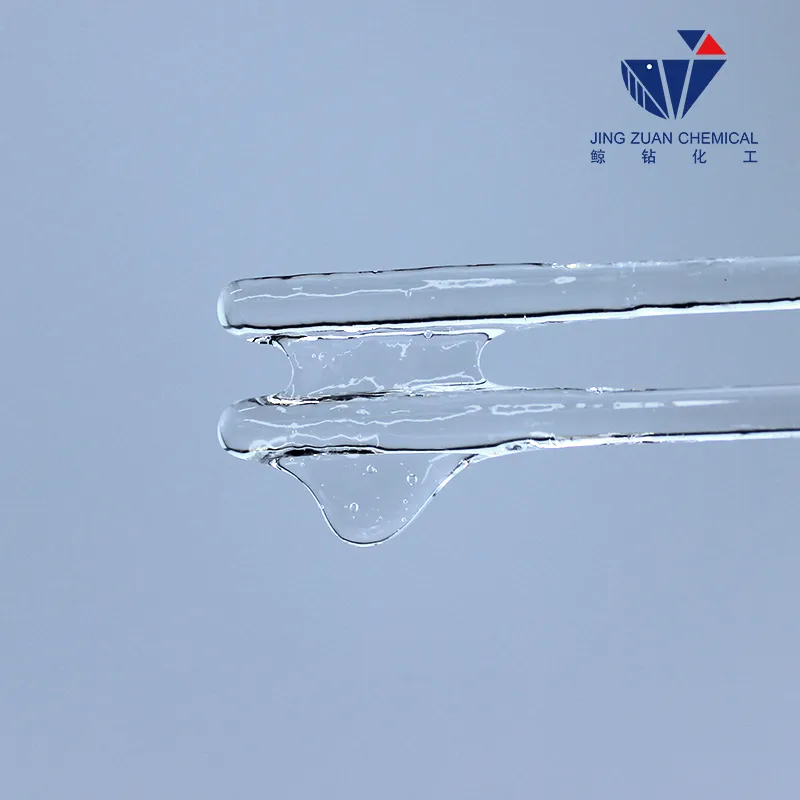

In summary, hydroxyethyl cellulose has been widely used in various fields due to its excellent thickening, stability, adhesion, emulsification, dispersion and other properties. With the continuous development of science and technology, the application fields of hydroxyethyl cellulose will continue to expand and deepen.

In summary, the properties of hydroxypropyl methylcellulose make it a multifunctional excipient in various industries. Its solubility, viscosity, film-forming capabilities, and stability, combined with its safety profile, establish HPMC as a cornerstone in formulation science. As industries continue to seek more efficient and effective ingredients, HPMC will remain a critical component in advancing product technology, meeting the growing demands for quality and performance across diverse applications.

In personal care, HPMC is used in formulations such as shampoos, conditioners, and skin care products. Its thickening ability allows formulators to create products with desirable viscosities while maintaining a smooth application. Furthermore, HPMC dispersions in personal care products can enhance the sensory experience for the user, making the product feel luxurious and hydrating.

Samenvattend, de prijs van redispersible polymeerpoeder is afhankelijk van een combinatie van factoren, waaronder de samenstelling, kwaliteit, vraag en aanbod, en geopolitieke omstandigheden. Voor consumenten en bedrijven is het belangrijk om niet alleen naar de prijs te kijken, maar ook naar de waarde en prestaties van het product. Het kiezen van het juiste type RDP kan een aanzienlijke impact hebben op de uiteindelijke kwaliteit en duurzaamheid van hun producten.

In conclusion, hydroxypropyl methylcellulose stands out as a key player in the construction industry, offering numerous advantages in workability, water retention, safety, and environmental sustainability. As demand for high-performance, eco-friendly construction materials grows, HPMC is poised to contribute significantly to the future of construction, paving the way for more durable, efficient, and responsible building solutions.

In conclusion, HPMC is a crucial compound that has established itself across diverse sectors due to its unique properties and functionalities. From enhancing food products to improving pharmaceutical formulations, HPMC’s versatility continues to make it an indispensable ingredient in modern industry. Its natural origins, coupled with its effectiveness, position HPMC as a favorable choice for manufacturers striving for quality and sustainability in their offerings. As research continues to unveil new applications and benefits, the future of HPMC remains bright, promising further innovations in the years to come.

Methyl Hydroxyethyl Cellulose (MHEC) is a versatile and essential compound in various industries, particularly in construction, pharmaceuticals, and personal care products. The rise of MHEC's popularity is closely linked to its unique properties, including thickening, stabilizing, and film-forming abilities. As the demand for MHEC continues to grow globally, the establishment of specialized factories dedicated to its production has become increasingly vital.