In today's fast-paced world, innovations continue to reshape industries, and one area experiencing transformative change is the textile and garment industry. Auto sewing, a technological advancement in automated sewing processes, is rapidly gaining traction as businesses seek efficiency, consistency, and cost-effectiveness. This article delves into the intricacies of auto sewing, its benefits, challenges, and its potential to revolutionize textile production.

In addition to functional benefits, the double needle adds a unique decorative element to sewing projects. The parallel lines of stitching can enhance the visual appeal of seams, adding texture and dimension. Dense decorative stitches are achievable, which can elevate the overall design of garments and home decor items. Many sewists utilize the double needle for topstitching, giving their projects a polished, professional look without complex techniques.

Top stitching serves multiple purposes. Primarily, it reinforces seams, preventing them from unraveling while also holding fabric layers together. This added strength is particularly important in high-stress areas like armholes or waistbands. Additionally, top stitching enhances the garment's aesthetic appeal, offering a polished, professional finish that can transform a simple design into a striking piece.

However, it is important to note that while double needles chain stitch sewing machines offer numerous benefits, they may not be suitable for every sewing task. For instance, in applications where a stronger, more secure seam is required, a lock-stitch machine may be more appropriate. Moreover, because chain stitches can unravel if not secured properly, additional techniques such as backstitching or using extra layers of fabric may be necessary in certain situations to prevent seam failure.

Industrial sewing machines for auto upholstery are engineered to handle a variety of materials, including leather, vinyl, and specialized fabrics that are commonly used in vehicles. These machines are built for durability, as they need to sew through multiple layers of thick materials while maintaining precise stitch quality. The average automobile can have intricate stitching designs, which require high-speed and accurate sewing machines to ensure a flawless finish.

Automatic quilting machines have revolutionized the way quilts are made, making the process faster, more efficient, and ultimately more precise. These machines are designed to handle the intricate patterns and stitching required for quilting, which can be difficult to achieve by hand. By automating the quilting process, manufacturers and hobbyists alike can increase their productivity and produce high-quality quilts with ease.

When sewing stretchy fabrics, a regular sewing machine often produces seams that can easily break or pucker. An overlocker excels in this domain, as it can create stretch seams that allow the fabric to move freely without compromising structural integrity. This technique is excellent for constructing athletic wear, swimwear, and fitted garments, ensuring a comfortable fit and flexibility.

The two needle stitch, as the name suggests, employs two needles simultaneously to create a pair of parallel rows of stitching. Typically, this technique is executed on a specialized sewing machine equipped with two needles and a twin needle feed, allowing for even and consistent stitching along both lines. This method is particularly popular in the fashion industry, especially in creating garments that require durability and a stylish finish.

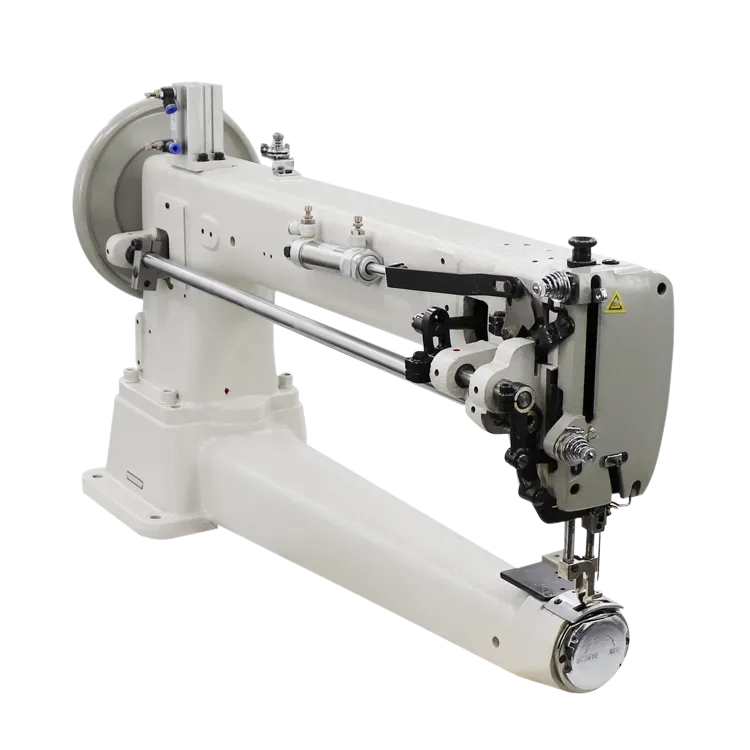

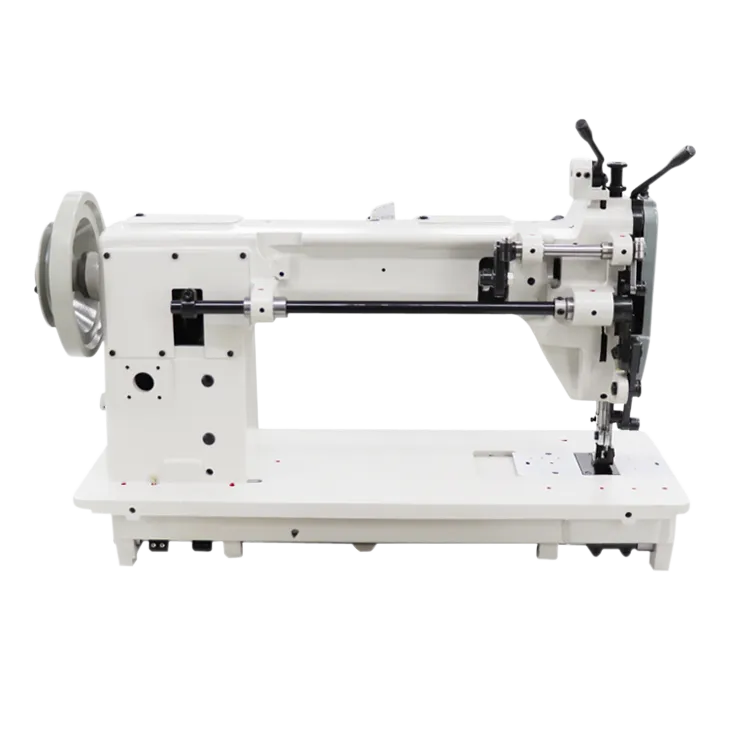

One of the key features of a compound feed heavy-duty sewing machine is its enhanced feeding mechanism. This type of sewing machine typically has two feed mechanisms – one on the presser foot and one on the needle bar. This dual feed system ensures that the fabric is fed evenly through the machine, preventing slippage, puckering, and uneven stitches. As a result, you can achieve perfectly aligned seams, stitching, and patterns even on thick or hard-to-handle materials.