Another critical property of EPDM is its superior elasticity and flexibility. This synthetic rubber can be easily molded and shaped, allowing for a wide range of applications. EPDM is also resistant to steam, water, and a variety of chemicals, including alkalis and dilute acids, making it suitable for use in diverse environments. Moreover, it has good electrical insulation properties, further broadening its applicability in various industrial sectors.

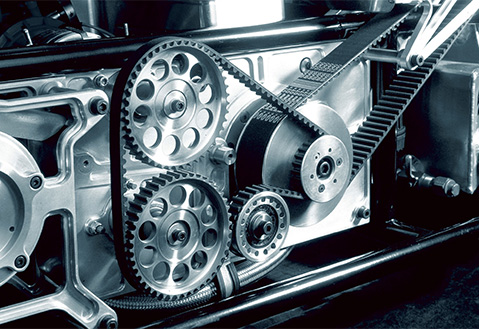

In a Peugeot engine, the timing belt helps to maintain the precise timing required for optimal performance. It is a toothed belt that connects the crankshaft to the camshaft(s); this enables the engine to perform smoothly and efficiently. As the engine runs, the crankshaft rotates, which in turn drives the camshaft via the timing belt. This synchronization is vital because if the timing is off, the engine may not run properly, leading to decreased power and fuel efficiency.

Poly belts, often referred to as polyurethane or elastic belts, are made from advanced synthetic materials. Unlike traditional rubber belts, poly belts offer enhanced resilience and durability owing to their superior material properties. They can withstand extreme temperatures, resist abrasions, and are less susceptible to wear and tear. This makes them an excellent choice for demanding environments where reliability is essential.

Een slipende aandrijfriem betekent dat de riem niet goed meer grip heeft op de schijven waaraan hij is bevestigd. Dit kan verschillende oorzaken hebben, waaronder slijtage, olie- of vuilafzetting op de riem of de schijven, en een onjuiste spanning van de riem. Wanneer de riem slipt, kan dit resulteren in een vermindering van de overdracht van vermogen, wat leidt tot een verminderde efficiëntie van het systeem.

When it comes to power transmission in various machines and applications, belts play a crucial role in ensuring efficiency and reliability. Among the different types of belts available, the J section poly V belt stands out for its unique characteristics and advantages. This article aims to explore the features, applications, and benefits of the J section poly V belt, providing a comprehensive understanding of its significance in modern machinery.

In the industrial sector, 8PK belts are employed in conveyor systems, material handling equipment, and automation machinery. Their design facilitates efficient movement of materials and products, enhancing productivity and workflow. The adaptability of the 8PK belt also means it can be customized for specific applications, allowing engineers to fine-tune machinery for optimal performance.

The efficiency of a conveyor system can be drastically affected by its belt teeth. When properly designed and maintained, conveyor belt teeth reduce the risk of material slippage, which in turn enhances productivity. In industries such as mining, manufacturing, and logistics, where time is of the essence, having an effective belt system can save both time and labor costs.

When it comes to the intricate machinery of an automobile, the engine is undoubtedly the heart that powers the vehicle. Yet, a myriad of components work harmoniously to ensure this heart beats efficiently. Among these components, the engine belt plays a crucial role that cannot be overlooked. Understanding car engine belts—what they are, the types available, and how to maintain them—ensures vehicle longevity and optimal performance.

When it comes to the maintenance and performance of Honda vehicles, the importance of the v-belt cannot be underestimated. The v-belt, often referred to as serpentine or drive belt, plays a crucial role in the operation of several engine components, including the alternator, power steering pump, water pump, and air conditioning compressor. In this article, we will explore the function of v-belts in Honda cars, their types, maintenance tips, and replacement recommendations.

V-belts are an essential component in mechanical transmission systems, widely utilized across various industries due to their efficiency, durability, and adaptability. With a unique trapezoidal cross-section, V-belts are designed to fit into pulleys, providing a firm grip that allows them to transfer power effectively from one rotating shaft to another. This article explores the significance of V-belts in transmission systems and their key advantages.