In industrial machinery, universal coil springs are used in various equipment, including conveyor systems and automated assembly lines. They play a pivotal role in absorbing vibrations, maintaining tension in belts, and ensuring consistent operation of moving parts. Furthermore, they are employed in everyday products such as mattresses, office chairs, and appliances, contributing to comfort and functionality.

Another important characteristic is the material used in the production of coil springs. High-carbon steel and stainless steel are common choices due to their tensile strength, resistance to fatigue, and ability to withstand harsh environments. Additionally, the surface finish of the spring, whether coated or untreated, can influence its performance and longevity, especially in corrosive or high-load applications.

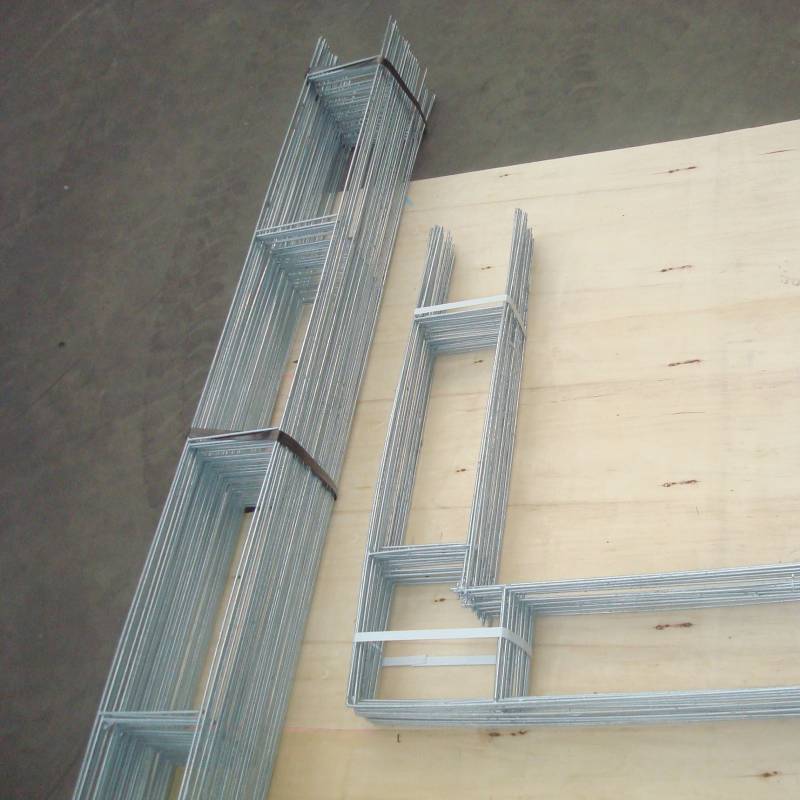

In summary, when considering cattle fencing, potential buyers must take into account several factors that influence price, including the type of fencing, materials, length, labor, terrain, and local laws. Investing in quality fencing is essential for the long-term welfare of cattle and the overall productivity of the farming operation. While it may be tempting to choose the cheapest option available, understanding the trade-offs in durability and effectiveness can ultimately lead to more informed decisions that will protect both the cattle and the land they graze on. As prices can vary, it's advisable to seek multiple quotes and consult with fencing professionals to ensure the best investment for your specific needs.

3. Versatility Besides containing cattle, these panels can be used for various applications. They are ideal for creating small pens for livestock, managing livestock during veterinary visits, or even for establishing safe zones for calves. Some ranchers utilize cattle panels to build shelters, fences for gardens, or even as structural support for greenhouses.

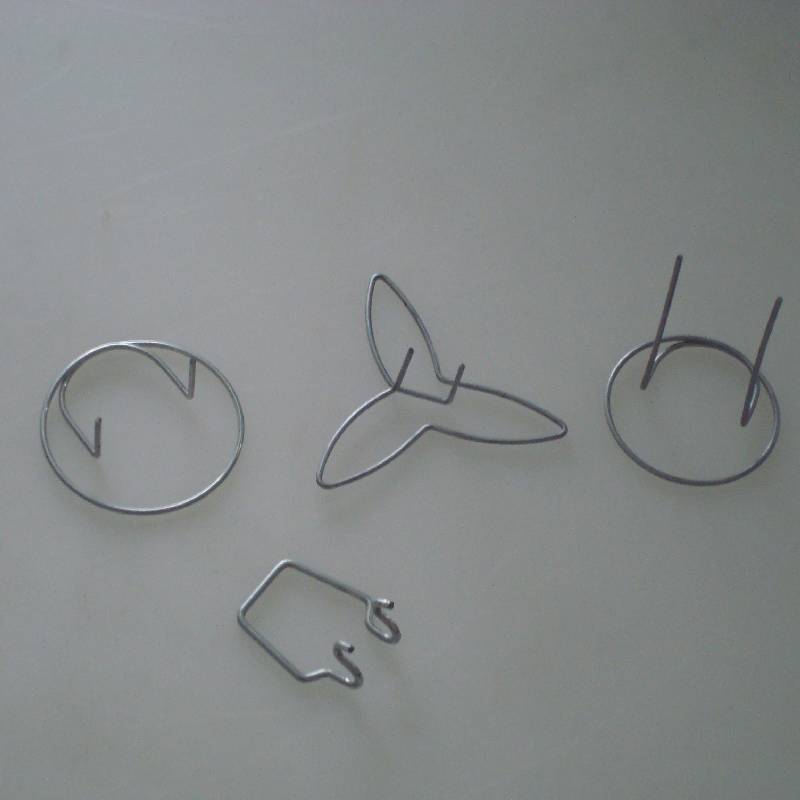

Coil springs are an essential component in a multitude of mechanical systems, functioning as energy storage devices that help manage the forces exerted in various applications. Among these types, tiny coil springs, often referred to as micro springs or miniature coil springs, play a crucial role in a range of fields including electronics, automotive, medical devices, and consumer products. Their compact size and unique properties make them indispensable in many modern engineering solutions.

Masonry triangle ties are typically triangular-shaped metal components that connect masonry walls to structural supports, such as framing or additional masonry elements. These ties are designed to enhance the bond between different materials, providing additional support to withstand various stresses that a building might encounter, including wind loading, seismic activity, and temperature fluctuations.

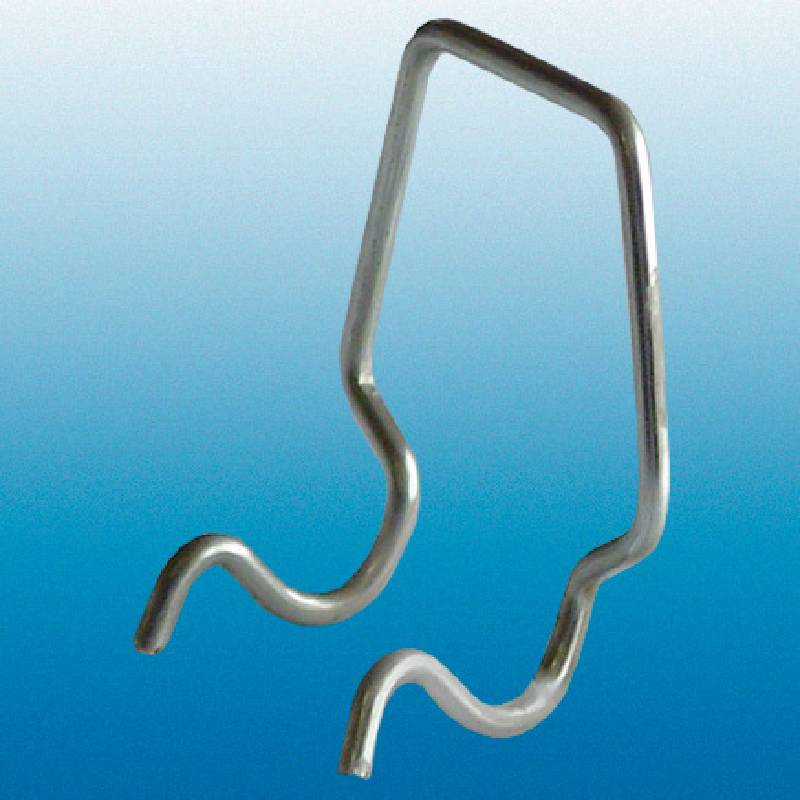

The demand for extension springs has seen significant growth in recent years, driven by advancements in technology and the expansion of various industries. The automotive sector, for instance, relies heavily on precision-engineered springs for components such as hoods, trunk closures, and suspension systems. As electric and autonomous vehicles become more prevalent, the demand for innovative spring designs will continue to rise.

Compression springs are essential components in various engineering applications, providing resistance to compressive forces. These spiral springs are commonly found in machinery, automotive systems, gadgets, and many other devices. Understanding the different types of compression springs can help engineers and designers choose the right type for their specific application. This article will explore the main types of compression springs, their characteristics, and typical uses.

Extension springs are a crucial component in various mechanical systems, providing essential tensioning and support. These springs are designed to absorb energy and return it to the users in a controlled manner. A significant aspect of extension springs is their hooking mechanism, which allows them to be anchored or connected to other components. In this article, we'll explore the different types of hooks associated with extension springs, their functions, and applications.

Micro extension springs are small, elastic devices crafted from coiled wire that can withstand forces applied to them. They are characterized by their small diameter and length, making them suitable for use in sensitive equipment such as medical devices, precision instruments, and miniature machinery. Despite their size, micro extension springs are engineered to provide significant tensile strength, allowing them to perform effectively in demanding environments.

Gold wire is another luxurious option, often used in high-end jewelry. It can be found in different karats, with 14k and 18k being the most popular for jewelry making. Gold wire provides a beautiful, warm tone and is highly resistant to tarnishing, making it a durable option for long-lasting pieces. It is, however, the most expensive type of wire, making it best suited for special occasions or valuable creations.