One of the most notable features of HEC is its ability to form gels and thick solutions when mixed with water, without the need for additional emulsifiers or surfactants. This characteristic makes HEC particularly desirable in formulations requiring stability under various conditions. Additionally, HEC is chemically stable, resistant to microbial degradation, and does not react with most ionic compounds, making it a reliable ingredient in diverse products.

In conclusion, the study of cell size and Hec provides critical insights into the functional dynamics of cells in biological systems. These metrics enhance our understanding of how cells adapt to their environment, their role in health and disease, and their evolutionary significance. As research continues to evolve, the implications of such studies will undoubtedly broaden our comprehension of cellular biology, with potential applications ranging from improving agricultural practices to developing novel therapeutic strategies for diseases. The interplay between cell size and its various physiological implications underscores the complexity and adaptability of life at the cellular level.

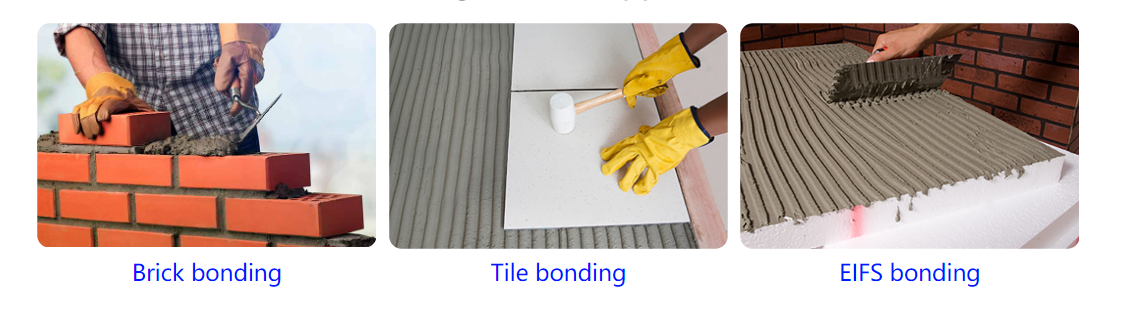

The incorporation of Hydroxypropyl Methylcellulose (HPMC) into mortar formulations is a game changer in the construction industry. Its ability to enhance workability, increase water retention, improve adhesion, reduce shrinkage, and extend open time makes it an invaluable additive for various applications. As the construction industry continues to evolve, the role of HPMC in improving mortar performance remains significant, ensuring that structures are built to withstand the test of time while meeting the demands of modern construction practices. Whether it's a tiled floor, a stucco facade, or a sturdy masonry wall, HPMC plays a crucial role in enhancing the efficiency and durability of mortar systems.

In the food industry, HPMC is valued for its ability to enhance texture and consistency. It acts as a thickening and stabilizing agent, particularly in sauces, dressings, and dairy products. HPMC is also used in gluten-free baked goods, helping to improve the elasticity and moisture retention that is often lacking when traditional wheat flour is omitted. Furthermore, it is found in various processed foods to provide a desirable mouthfeel and prevent ingredient separation. As a safe food additive, HPMC is approved by regulatory bodies like the U.S. Food and Drug Administration, making it a reliable option for food manufacturers seeking to maintain quality and consistency.

Hydroxyethyl cellulose is a versatile and valuable ingredient across multiple industries, thanks to its unique properties and capabilities. Its uses range from improving the consistency of pharmaceuticals and cosmetics to enhancing the texture of food products. As industries continue to seek natural and effective solutions, HEC stands out as an exemplary polymer that combines functionality with safety, demonstrating its importance in modern formulations. With ongoing research and development, the potential applications of hydroxyethyl cellulose are likely to continue expanding, solidifying its place as a key ingredient in many formulations.

In conclusion, the chemical structure of Hydroxypropyl Methylcellulose, characterized by its cellulose backbone and the strategic substitution of hydroxypropyl and methyl groups, bestows it with a unique set of properties. This versatility makes HPMC indispensable across various sectors, from pharmaceuticals to food processing and beyond. Understanding the chemical structure of HPMC not only highlights its functional attributes but also paves the way for innovations in product development, ensuring it remains a critical ingredient in modern formulations.

HPMC is also a crucial excipient in the pharmaceutical field. It is used as a binder and controlled-release agent in tablet formulations, enhancing the bioavailability of active ingredients. Its hydrophilic nature allows for sustained release of the drug, improving therapeutic effectiveness. Furthermore, HPMC is utilized in ophthalmic solutions as a lubricant, providing relief for dry eyes. Its compatibility with various active pharmaceutical ingredients makes it a preferred choice in many formulations, catering to a wide range of healthcare needs.

In the food industry, HPMC serves multiple roles. It is commonly used as a thickening agent, emulsifier, and stabilizer in various food products. Its ability to retain moisture makes it a popular choice for improving the texture and freshness of baked goods, as well as for enhancing the creaminess of sauces and dressings. Furthermore, HPMC is often employed in gluten-free products to mimic the texture that gluten provides, making it invaluable for catering to the growing demand for gluten-free options.

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether that has gained significant popularity across various industries due to its unique properties and functionalities. HPMC is a white, odorless, and tasteless powder that is soluble in cold water, forming a clear, viscous solution. Its remarkable ability to form gels, emulsify, and stabilize makes it an invaluable ingredient in a wide range of applications, including pharmaceuticals, food, cosmetics, and construction. This article explores the different types of HPMC and their specific applications.

Additionally, HPMC is used in hair care products, providing thickening and conditioning benefits. In facial cleansers and masks, it aids in the application and enhances the overall sensory experience of the product. Thanks to its gentle nature, HPMC is suitable for sensitive skin formulations, further broadening its appeal in cosmetic formulations.

As we continue to face global challenges, the role of efficient and sustainable materials like HPMC becomes increasingly important. The HPMC website stands at the forefront of this evolution, offering a platform for sharing best practices, research breakthroughs, and innovative applications. By fostering collaboration and disseminating vital information, the website supports the growth of industries that depend on HPMC, ensuring that stakeholders can make informed decisions that benefit both business and society.

Hydroxypropyl Methylcellulose is a semi-synthetic polymer formed by modifying cellulose through the introduction of hydroxypropyl and methyl groups. This modification enhances the solubility of cellulose in water, making HPMC an effective thickening agent, binder, and film-forming agent. HPMC is commonly produced in various grades, which differ in their levels of hydroxypropyl and methyl substitution. These variations in substitution degrees affect the viscosity, solubility, and other properties that determine its suitability for different applications.