Rubber strip window seals are designed to prevent air leaks and water infiltration, which are common concerns for homeowners. By effectively sealing the gaps around windows, these strips help maintain a consistent indoor temperature and reduce energy bills, making them an essential component of modern window technology. Factories producing these rubber seals play a crucial role in the supply chain, ensuring that high-quality materials are available to contractors, builders, and individual consumers.

While the opportunities are plentiful, there are also challenges that exporters of glass window seal strips must navigate. Fluctuating raw material prices and supply chain disruptions can impact production costs and timelines. Moreover, understanding and adhering to varying international standards can be daunting for companies without prior experience in the export sector. Therefore, it is crucial for businesses to conduct thorough market research, foster strong relationships with local distributors, and stay updated on industry trends and regulations.

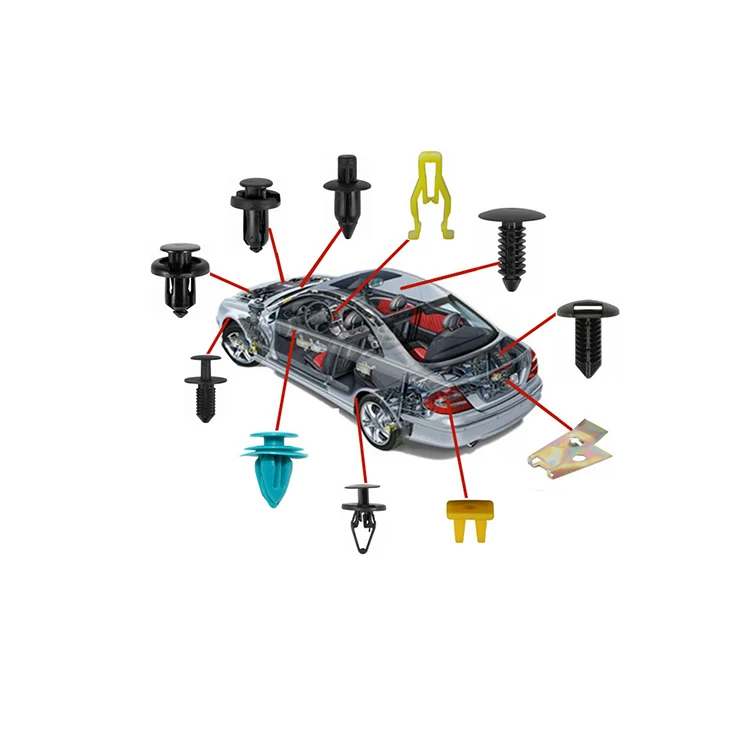

As the automotive industry continues to evolve, the role of car window seal strip exporters will remain critical in ensuring vehicle quality, safety, and comfort. By focusing on material innovation, sustainability, and customization, these exporters play a pivotal role in shaping the standards of modern vehicle design. For manufacturers, partnering with reputable exporters can lead to enhanced product performance and customer satisfaction, ultimately driving success in an ever-competitive marketplace. As global demand for automobiles continues to rise, the relationship between manufacturers and window seal strip exporters will be more important than ever in building the cars of the future.

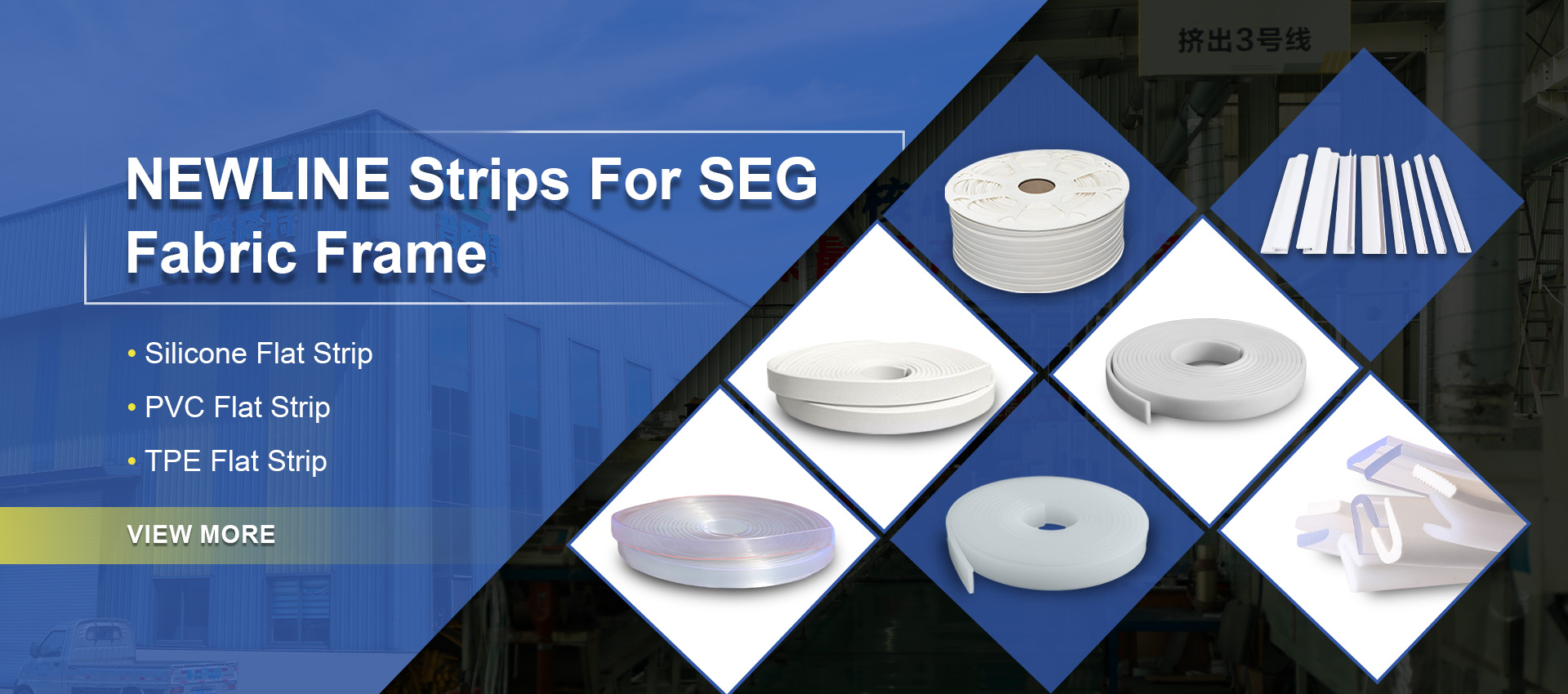

In the HVAC (heating, ventilation, and air conditioning) sector, flat rubber seal strips help create airtight seals around ducts and vents, ensuring energy efficiency and optimized performance. Moreover, they find applications in electronics, appliances, and even marine industries where sealing and insulation are imperative.

Silicone foam seal strips are made from a blend of silicone rubber and foam. This unique composition allows for the production of flexible, durable, and lightweight strips that can create a reliable seal against dust, moisture, and air infiltration. The foam aspect provides a cushioning effect, which not only contributes to sound dampening but also helps in vibration absorption. These properties make silicone foam seal strips an ideal choice for various applications, from sealing windows and doors to insulating electronic devices.

In conclusion, DS Brown's strip seal products are an essential component for any construction or infrastructure project that requires reliable sealing solutions. Their combination of durability, design flexibility, ease of installation, and cost-effectiveness make them a top choice for engineers and contractors alike. As infrastructure continues to age and require upgrades, the role of high-quality materials like those offered by DS Brown will become increasingly crucial in ensuring safety and longevity. Investing in DS Brown strip seal products is not just a choice; it’s a commitment to excellence in construction.

1. Energy Efficiency One of the primary advantages of LED technology is its energy efficiency. LED neon tube lights consume significantly less power than traditional neon lights, leading to lower electricity bills. Additionally, LEDs have a longer lifespan, often lasting up to 50,000 hours or more, which reduces the need for frequent replacements.

The ELAN 2S Chrome Rocker Trim Strip is versatile, making it suitable for a wide range of vehicles, from sedans to SUVs. Moreover, it can be combined with other chrome accessories, such as grille trims or mirror covers, to create a cohesive look that accentuates your vehicle's style. Customization options are abundant, with varying lengths and widths available to cater to different preferences and vehicle models. This adaptability allows car owners to create a personalized touch that reflects their unique style.

Square rubber seal strips are typically made from materials such as silicone, EPDM (Ethylene Propylene Diene Monomer), or neoprene. These materials are chosen for their durability, flexibility, and resistance to various environmental factors, such as extreme temperatures, moisture, and chemicals. The square shape of these strips allows for a secure fit within grooves or channels, ensuring a tight seal that minimizes leakage and enhances insulation.