Most shower glass frame seal strips are made from flexible PVC, rubber, or silicone. Each material has its own set of benefits. For instance, silicone offers excellent durability and resistance to extreme temperatures, making it particularly suited for bathroom environments. PVC, while often more affordable, may not offer the same level of flexibility or longevity. CE certified seal strips will typically indicate the material used and its compliance with relevant European standards for safety and performance.

The process of manufacturing aluminum strips typically involves several steps, including melting, casting, rolling, and finishing. Initially, aluminum is melted in a furnace where impurities are removed. The molten aluminum is then cast into slabs, which are subsequently rolled into thin strips. Finish treatments such as anodization or painting can be applied to enhance durability and aesthetics according to specific needs.

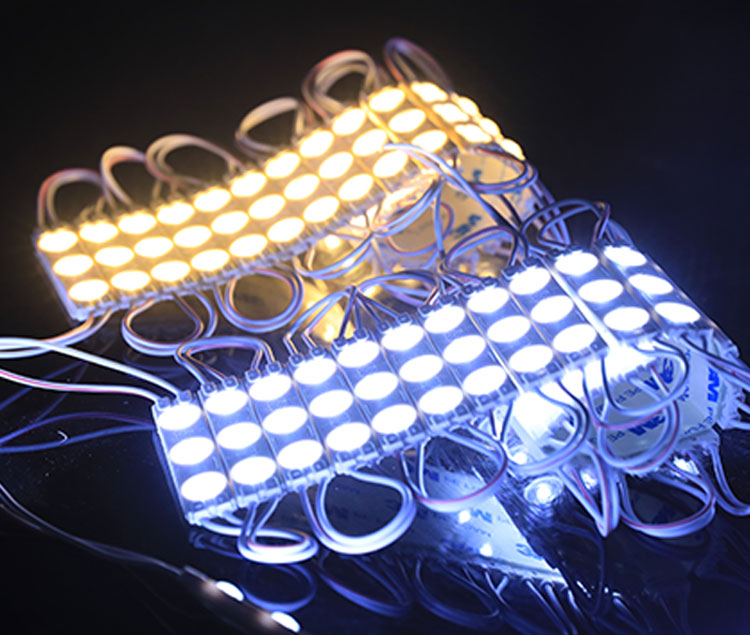

Furthermore, as technology continues to advance, LED neon wall light companies are exploring smart lighting options. Integration with home automation systems allows users to control their lighting through smartphone apps, creating personalized lighting experiences that can be adjusted based on mood, time of day, or activity. Such innovations are poised to further revolutionize the market, providing added value and convenience for consumers.

In the ever-evolving world of consumer products, safety and quality assurance play a crucial role in determining the market success of any item. Among the myriad of products available today, TPE (Thermoplastic Elastomer) silicone light box fabrics have emerged as a popular choice due to their versatility, durability, and aesthetic appeal. However, for manufacturers and consumers alike, understanding certification standards like CE marking is crucial.

One of the most appealing aspects of 3D side light pass strips is their versatility. They can be used in various settings, including residential homes, commercial spaces, and outdoor environments. For instance, in a modern home, they can accentuate architectural features, highlight artwork, or define zones within an open concept layout. In commercial spaces, these strips can be used to guide customers through a store or create a welcoming atmosphere in restaurants and lounges.

In the world of manufacturing and construction, the significance of quality components cannot be overstated. Among these essential components, seal strips play a crucial role in ensuring durability, efficiency, and overall product performance. P Seal Strip Company has emerged as a leader in the industry, providing innovative sealing solutions that cater to various applications.

Wholesale weather door seal strips are a small yet essential component in enhancing a home’s energy efficiency and comfort. By effectively sealing gaps around doors, these strips not only help maintain a stable indoor climate but also add to the aesthetic appeal of a home. When selecting the right seal strips, consider the various materials, widths, and thicknesses available, and always prioritize quality to ensure long-lasting performance. By making this small investment, you can enjoy significant savings on energy costs and create a more welcoming living environment for you and your family.

Moreover, the environmental implications of 3D high polymer ABS strip factories are noteworthy. As sustainability becomes a more pressing concern, these factories can play a role in reducing carbon footprints. Unlike traditional manufacturing, which often involves fossil fuel consumption and large-scale waste, 3D printing is inherently more sustainable. It optimizes material usage and minimizes excess, contributing to lower energy consumption and reduced emissions.