half inch welded wire

-

4mm set screw

The Importance of 4mm Set Screws in Mechanical Applications In various mechanical applications, fast...

-

80mm Round Fence Posts for Durable and Stylish Enclosure Solutions

Understanding 80mm Round Fence Posts Features and Benefits When it comes to constructing fences, the...

-

chain link fence gate frame

The Importance and Design of Chain Link Fence Gate Frames Chain link fences are a popular choice for...

-

10mm Set Screw - Hoogwaardige Bevestigingsmiddelen

10mm Set Schraube Een Cruciale Component voor Mechanische Toepassingen De 10mm set schroef is een es...

-

Durable 3ft x 3ft Garden Fence Panels for Enhanced Outdoor Spaces and Security

The Versatility of 3ft x 3ft Fence Panels A Perfect Choice for Your Outdoor Space When it comes to e...

-

6 ft tall chain link gate

The Versatility of a 6-Ft Tall Chain Link Gate Chain link gates are an essential component in many f...

-

Building a Safe and Secure Rabbit Cage Using Chicken Wire for Your Pets' Comfort

The Benefits of Using Chicken Wire for Rabbit Cages When it comes to constructing a safe and comfort...

-

Befestigung von Tor an T-Pfosten

Das Anbringen eines Tors an einem T-Post Das Anbringen eines Tors an einem T-Post ist eine effektive...

-

1 2 medidor de fios de bobina

Fio de Bobina 1% 202 Versatilidade e Aplicações no Mercado O fio de bobina 1% 202 tem ganhado destaq...

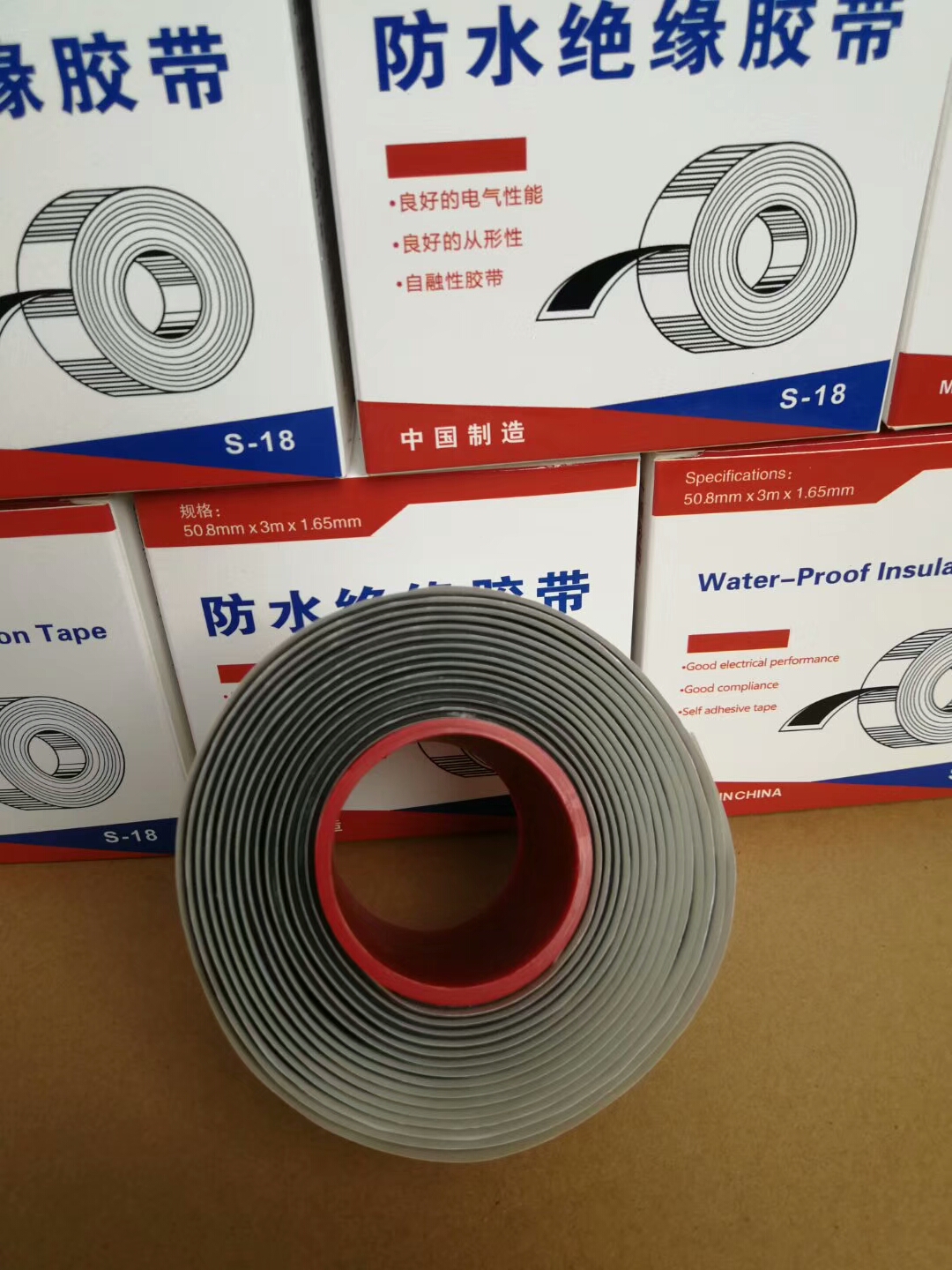

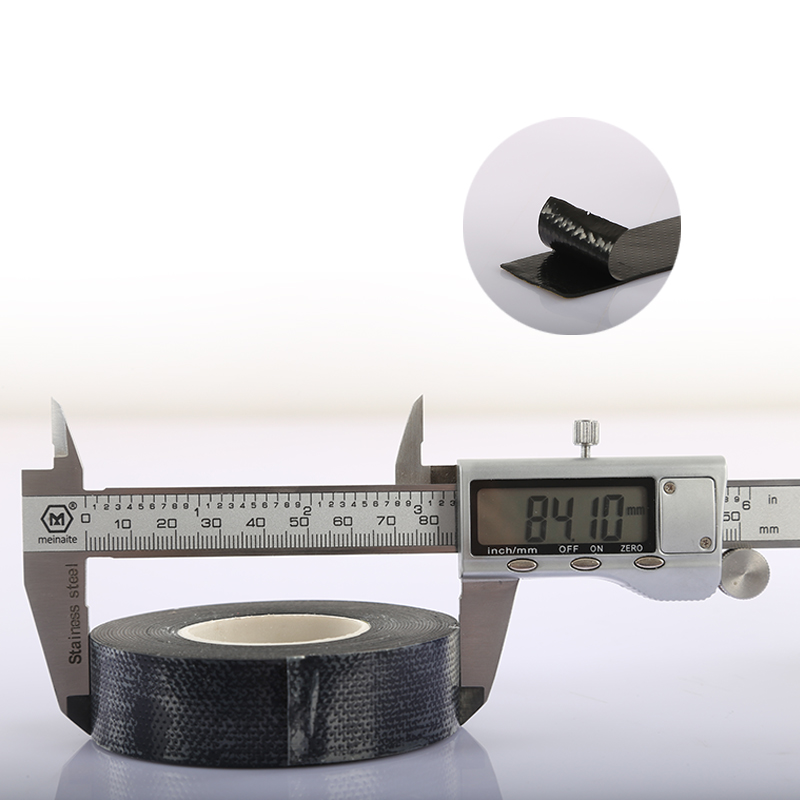

tape insulation pvc. It can be easily wrapped around wires and cables, requiring minimal tools and expertise. Its self-adhesive property ensures a firm grip, eliminating the need for additional sealing or binding materials. The versatility of rubber tape extends beyond plumbing tasks

tape insulation pvc. It can be easily wrapped around wires and cables, requiring minimal tools and expertise. Its self-adhesive property ensures a firm grip, eliminating the need for additional sealing or binding materials. The versatility of rubber tape extends beyond plumbing tasks rubber tape for leaks. It can be used to patch up small holes in hoses, seal around windows and doors to prevent drafts, and even serve as a temporary fix for leaky roofs. Its weatherproof nature means it can withstand various climate conditions, making it suitable for indoor and outdoor applications.

rubber tape for leaks. It can be used to patch up small holes in hoses, seal around windows and doors to prevent drafts, and even serve as a temporary fix for leaky roofs. Its weatherproof nature means it can withstand various climate conditions, making it suitable for indoor and outdoor applications.

It allows you to see what is underneath the tape, making it easier to accurately place and align It allows you to see what is underneath the tape, making it easier to accurately place and align

It allows you to see what is underneath the tape, making it easier to accurately place and align It allows you to see what is underneath the tape, making it easier to accurately place and align