SMC panel water tanks represent a significant advancement in water storage technology. Their combination of durability, ease of installation, and hygienic design makes them an optimal choice for many sectors. As water scarcity continues to be a pressing global issue, the need for efficient storage solutions like SMC panel tanks is more relevant than ever. Whether for personal, commercial, or industrial use, investing in these innovative water storage systems will ensure a sustainable and reliable water supply for the future.

Historically, tanks were predominantly constructed as large, single units, which could pose challenges in terms of transport and installation. As technology has advanced, the design of sectional tanks has evolved to incorporate innovative materials and improved engineering techniques. Modern sectional tanks often employ high-strength steel, corrosion-resistant coatings, and advanced welding methods, ensuring longevity and stability.

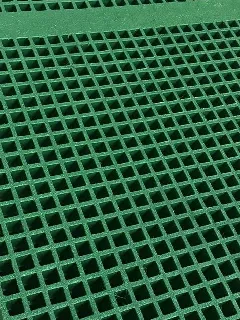

Corrosion resistance is another standout feature of FRP vessels. Many industries deal with harsh chemicals and corrosive environments that can rapidly degrade traditional materials. FRP vessels can be engineered to withstand a wide range of chemicals, including acids, alkalis, and solvents, making them suitable for use in chemical processing plants, wastewater treatment facilities, and other demanding environments. This resistance not only extends the lifespan of the vessels but also reduces maintenance costs and downtime, leading to enhanced operational efficiency.

Moreover, FRP treads are low-maintenance. They do not require painting, coating, or other forms of upkeep that traditional materials might need. Their long-lasting performance ensures that once installed, they will not need frequent replacements or repairs, reducing maintenance costs over time. This makes FRP treads a cost-effective and practical solution for businesses looking to minimize long-term expenditure.

In conclusion, GRP insulated water tanks represent a modern solution to water storage challenges. Their outstanding insulation properties, coupled with durability and low maintenance, make them a cost-effective choice for various applications. As we strive for more sustainable and efficient water management practices, GRP insulated water tanks stand out as a formidable option, offering a blend of practicality and environmental responsibility. Whether for residential use, agricultural purposes, or industrial applications, investing in a GRP insulated water tank is a move towards enhanced efficiency and reliability in water storage.

In conclusion, metal bar grating represents a cornerstone of modern construction and industrial applications. Its unique combination of strength, versatility, and safety features makes it an ideal choice for a wide range of settings, from heavy-duty industrial use to elegant architectural designs. As the demand for efficient and sustainable building materials continues to rise, metal bar grating remains a reliable solution that meets the evolving needs of various industries. Whether it’s serving as a structural element or a decorative feature, metal bar grating is a testament to the ingenuity of modern engineering.

Fiberglass reinforced plastic (FRP) is a composite material made of a polymer matrix reinforced with fiberglass. This combination results in a material that is not only strong and durable but also resistant to a range of environmental factors, including chemicals, UV radiation, and temperature variations. These qualities make FRP tanks suitable for various uses in the water treatment industry, agricultural storage, chemical storage, and more.

Bar grating is a construction material composed of a series of parallel steel bars joined together, often by welding or mechanical means. These bars create an open grid pattern, allowing light, air, and water to pass through while providing a sturdy walking surface or platform. Bar grating can be made from a variety of materials, including galvanized steel, stainless steel, and fiberglass, each offering unique characteristics and benefits.

Aluminum bar grating is a vital component widely used in various industries due to its exceptional strength, lightweight properties, and corrosion resistance. This type of grating is constructed from flat bars created from high-quality aluminum, which are engineered to create a durable, slip-resistant surface ideal for a multitude of applications. In this article, we will explore the features, benefits, and typical uses of aluminum bar grating.