Moreover, the export of galvanized iron wire mesh plays a crucial role in China’s trade surplus. It allows for the expansion of markets and reinforces China’s position as a key player in global manufacturing. Major consumer countries, such as the United States, India, and various nations in Europe and Southeast Asia, rely on Chinese factories for their supply needs.

Polythene sheets are available in a variety of colors, thicknesses, and finishes, which allows for versatility in design. Homeowners and builders in China can select sheets that complement the aesthetic of their structures while still benefiting from their practical properties. Whether for residential, agricultural, or industrial buildings, polythene sheets offer a range of options that can suit different architectural styles and functional needs.

In den Fabriken wird zunächst Zinn in Form von Barren oder Blechen angeliefert. Die Handwerker schneiden, formen und giessen das Zinn in die gewünschten Formen. Es können verschiedene Techniken Anwendung finden, darunter das Walzen, Gießen oder das Treiben, bei dem das Zinn mit einem Hammer in die gewünschte Form gebracht wird. Diese Techniken erfordern viel Geschick und Präzision, um ein qualitativ hochwertiges Endprodukt zu garantieren.

Selecting the right roofing sheet manufacturer is a significant decision that can affect the integrity and aesthetics of your building for years to come. Take the time to research various manufacturers, comparing their products, services, and reputations within the industry. By prioritizing quality, customization, sustainability, and customer support, you can ensure that your investment in roofing sheets pays off, providing you with a sturdy and stylish roof that meets your needs.

In conclusion, sheet metal roofs have emerged as a leading choice in the construction industry due to their durability, environmental sustainability, aesthetic versatility, cost-effectiveness, and advanced manufacturing techniques. As more builders and homeowners recognize the myriad benefits of sheet metal, the demand for high-quality roofing solutions from specialized sheet metal factories continues to rise. By opting for sheet metal roofing, clients can invest in a long-lasting, eco-friendly, and visually appealing solution that meets the needs of modern construction.

As the day comes to an end, the factory holds a special event known as the Eevee Celebration, where families can participate in crafting their own mini lunch boxes. Guided by the Tin Crafters, children get hands-on experience in tin crafting, learning skills while letting their creativity soar. This interactive event is a highlight for many, fostering a sense of community and connection among participants. Tales of Eevee adventures and shared laughter fill the air, creating cherished memories that will last a lifetime.

Galvanized iron wire mesh is produced by coating iron wire with a layer of zinc to prevent rust and extend its lifespan. This protective layer makes the wire mesh suitable for outdoor applications where it is exposed to moisture. The mesh is known for its strength, durability, and resistance to corrosion, making it a popular choice in fencing, industrial sieving, and as a support structure in construction.

In summary, while sheet metal roofing can represent a higher upfront cost compared to traditional materials like asphalt shingles, its longevity, and durability often result in lower long-term expenses and greater overall value. Investing in quality sheet metal roofing ensures a secure, sustainable, and stylish roof that stands the test of time.

When it comes to construction and roofing materials, metal roofing has gained substantial popularity due to its durability, longevity, and energy efficiency. Among the various types of metal roofing systems, PBR (Purlin Bearing Rib) panels stand out as a highly functional choice for commercial and residential applications. This article explores PBR metal roofing suppliers, their offerings, and the advantages of opting for PBR panels in your next roofing project.

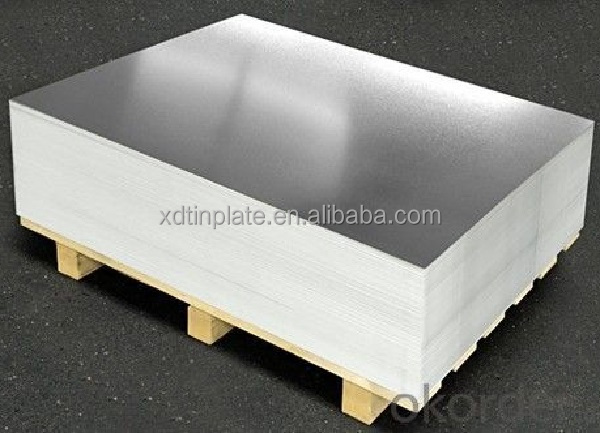

Galvanized iron sheets are essential materials widely utilized in various industries, primarily due to their excellent strength, durability, and resistance to corrosion. The manufacturing process involves coating iron or steel sheets with a layer of zinc, which serves as a protective barrier against rust and oxidation. One critical factor that buyers must consider when purchasing galvanized iron sheets is the thickness of the material, as it plays a crucial role in determining the sheet's applications and longevity.

Moreover, when planning maintenance schedules, the known friction characteristics of galvanized pipes allow for predictive modeling of performance over time. As pipes age, the internal surface may become rougher due to corrosion or deposits, leading to an increase in the friction factor. Regular maintenance checks can help mitigate these effects, ensuring that the system operates efficiently over its lifespan.

In addition to their functional attributes, roof cover sheets also enhance the overall appearance of a building. With advancements in manufacturing techniques, these products come in various colors, textures, and finishes, allowing architects and homeowners to achieve their desired aesthetic while maintaining structural integrity.