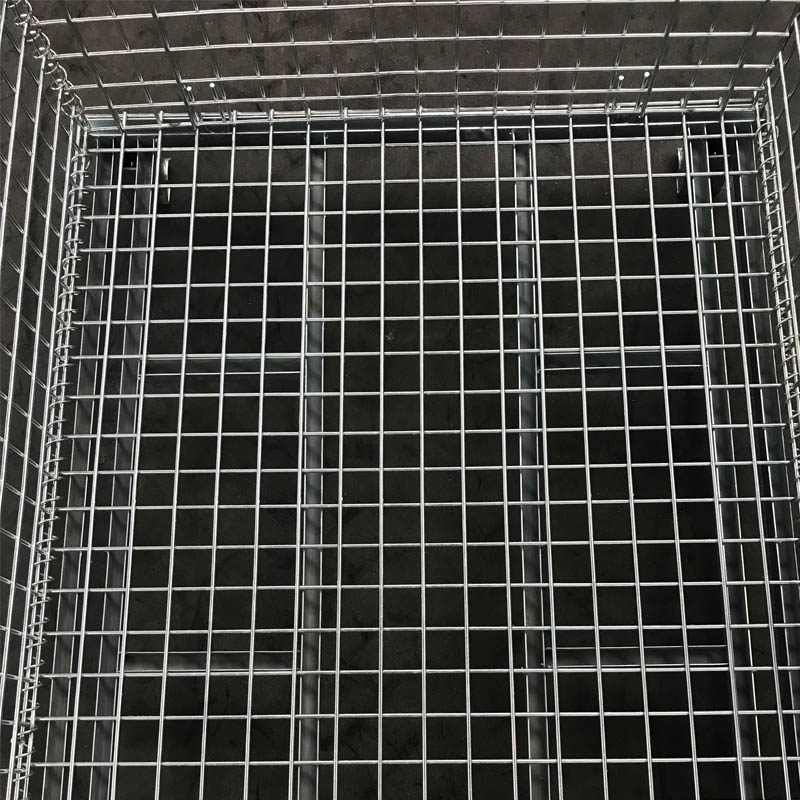

Stainless steel welded mesh has become an integral material in various industries due to its outstanding properties and versatility. This protective and structural product is created through the precise welding of stainless steel wires, forming a robust and consistent grid pattern. The unique features of stainless steel, coupled with its manufacturing process, contribute to its wide range of applications in construction, agriculture, architecture, and more.

One of the significant advantages of reinforcement wire mesh panels is their versatility. They can be used in various applications, including floors, pavements, walls, and even precast concrete products. Whether in residential, commercial, or industrial projects, these panels offer a reliable solution for reinforcing concrete structures. Additionally, they come in different gauges and configurations, allowing construction professionals to choose the most appropriate mesh type for specific project requirements.

Extension springs work in the opposite way to compression springs. The compression spring acts in reverse when it is pressed, and the extension springacts in reverse when it is stretched or pulled apart. When the two ends of the stretch spring pull apart, the spring tries to pull them back together. The spring occupies an important position in the global market, and is widely used in the fields of national defense, Marine, computer, electronics, automobile, mold, medicine, biochemistry, aerospace, railway, nuclear power, wind power, thermal power, construction machinery, mining machinery, construction machinery, elevator and so on.

In summary, 250mm cavity wall ties play a vital role in the construction of modern cavity walls, contributing to the overall stability, moisture control, and energy efficiency of buildings. As construction techniques continue to evolve, the importance of selecting the right wall tie material and dimensions cannot be overstated. With proper installation and selection, 250mm cavity wall ties will ensure robust structural integrity and prolonged durability in any building project.

The versatility of stanchion signs makes them suitable for numerous contexts. From trade shows and conventions, where they guide visitors through complex layouts, to restaurants and cafes, where they can help manage waiting lists and provide menus, the applications are limitless. Their portability allows them to be set up and taken down quickly, adapting to the dynamic nature of many industries.

Horizontal joint reinforcement plays a vital role in the structural integrity of CMU walls, addressing the challenges posed by lateral forces and enhancing overall wall performance. By improving load distribution, increasing flexibility, and reducing cracking, this reinforcement contributes to safer and longer-lasting structures. As the construction industry continues to evolve, the adoption of best practices, including the use of horizontal joint reinforcement, will remain crucial in delivering robust and resilient buildings that can withstand the test of time and environmental pressures.

2. Versatility Fine stainless steel mesh can be manufactured in various configurations, including sheets, rolls, and custom sizes. This versatility allows it to be tailored to specific needs across different industries. Whether used as a protective barrier, a decorative element, or a filtration device, fine stainless steel mesh adapts to various functions with ease.

Aluminum wire floral designs have increasingly become a popular craft within the realms of both professional florists and DIY enthusiasts. The versatility, malleability, and durability of aluminum wire make it an ideal material for creating stunning floral arrangements, sculptures, and decorative pieces. As we delve into the world of aluminum wire floral designs, we will explore its unique characteristics, the techniques involved, and its burgeoning popularity.

In conclusion, wall ties are an indispensable component of masonry construction. Their role in maintaining structural integrity, enhancing performance, and ensuring the longevity of buildings underscores the importance of proper installation and adherence to industry standards. As architecture continues to evolve, it is crucial for builders and designers to recognize the significance of wall ties and implement them effectively to create safe, durable, and aesthetically pleasing structures.

Concrete accessories encompass a wide range of products, including formwork systems, rebar supports, expansion joints, dowels, and curing compounds. Each of these accessories plays a unique role in ensuring that concrete is placed, set, and cured properly. For example, formwork systems are critical for shaping concrete into the desired structure while providing the necessary support during the curing process. Rebar supports and dowels are essential for reinforcing concrete, ensuring that tensile strength and load-bearing capacity are maintained.