Fan belts are critical for powering various components within a vehicle. They are responsible for transferring power from the engine to essential accessories such as the alternator, water pump, power steering pump, and air conditioning compressor. A well-functioning fan belt is essential not only for ensuring that these accessories work properly but also for maintaining the engine's overall health. If a fan belt fails, it can lead to serious issues, such as the overheating of the engine or a sudden loss of electrical power, which can be both dangerous and costly.

The 6.0% serpentine belt plays a vital role in ensuring the smooth operation of critical engine components. By understanding its function, importance, and maintenance requirements, vehicle owners can take proactive measures to protect their investment. Regular inspections, sound maintenance practices, and prompt attention to any issues can help ensure that your serpentine belt—and, by extension, your vehicle—remains in optimal working condition for years to come.

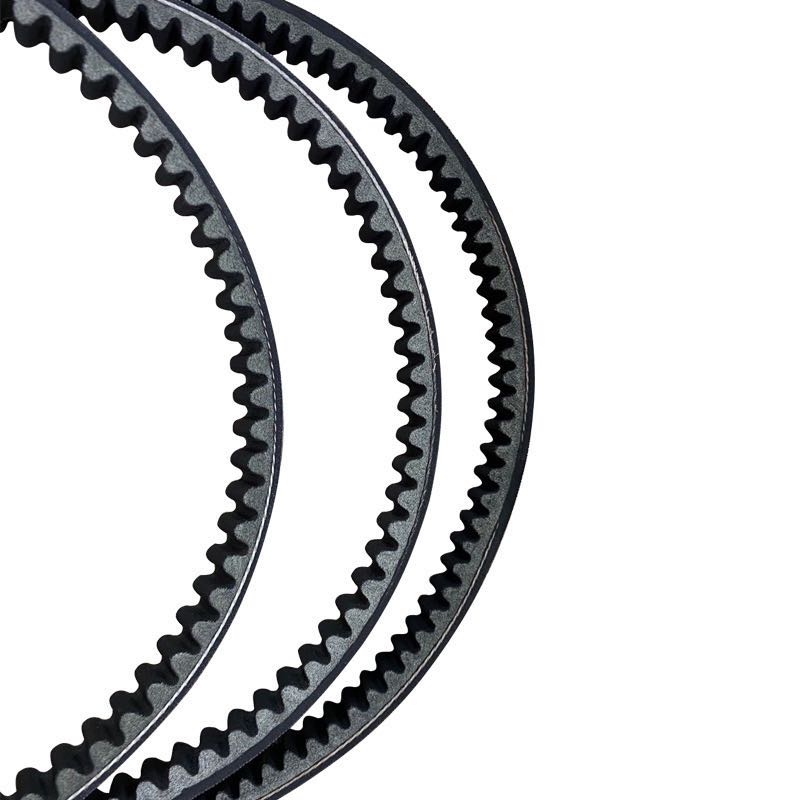

The tension of the V-belt is another critical factor in its performance. If the belt is too loose, it will slip, leading to a loss of power transmission and potential overheating of components. Conversely, if the belt is too tight, it can put excessive strain on the bearings of the driven accessories and the crankshaft, leading to premature failure. Most vehicles have tensioners that automatically maintain the correct tension, but they can wear out over time, necessitating replacement.

The automotive industry is well-known for its complexity and the integral role various components play in the smooth functioning of vehicles. Among these components, the W211 PK ribbed belt, often referred to as a serpentine belt, is vital for the operation of several engine accessories. This article delves into the features, functions, and importance of the W211 PK ribbed belt in vehicles, primarily focusing on the Mercedes-Benz W211 model.

In summary, the price of a timing belt can vary widely based on several factors, including brand, vehicle make and model, and installation costs. While it might be tempting to opt for cheaper options, investing in a high-quality timing belt can save you from expensive repairs caused by failure. Always consult your vehicle’s manual for specific maintenance intervals and recommendations. As with many aspects of car maintenance, the long-term costs associated with neglecting the timing belt far outweigh the initial savings. Remember, regular maintenance is key to ensuring the longevity and reliability of your vehicle. Making informed decisions regarding timing belt purchases and replacements will keep your engine running smoothly for years to come.

Flat V belts find utility in various industries including automotive, manufacturing, agribusiness, and more. In the automotive sector, they are commonly used in engine systems to drive alternators, water pumps, and air conditioning compressors. In manufacturing plants, flat V belts are crucial for connecting motors to conveyor belts, fans, and other machinery.

One of the most notable advantages of flat belts is their ability to handle different types of loads. Whether it's a light-duty application, like small-scale manufacturing or a heavy-duty system, flat belts can be custom-made to suit specific needs. Their design allows them to operate smoothly at varying speeds, making them suitable for both high-speed and low-speed applications. Furthermore, flat belts are less likely to slip compared to round belts, thus ensuring consistent performance.

In the realm of mechanical engineering and automotive design, belts are essential components that facilitate the transfer of power between various machinery and engine systems. Among the multitude of belt configurations, the 6PK 2140/6PK belt stands out as a vital element in many applications, particularly in automotive and industrial machinery. This article delves into the design, functionality, applications, and importance of the 6PK 2140/6PK belt in modern engineering.