The visual aesthetic of black metal is equally significant, embodying a style as distinctive as the music itself. The genre is known for its controversial imagery, including corpse paint and stark, foreboding artwork. Bands often adopt an androgynous appearance, emphasizing themes of death, decay, and the supernatural. This visual aspect serves not only as a marketing tool but also as a means of artistic expression, allowing musicians to convey their beliefs and emotions in ways that transcend mere words.

To ensure longevity, it is crucial to maintain plastic coated galvanized wire properly. Regular inspections for signs of wear, damage, or deterioration are recommended. If any areas of the plastic coating become damaged, it is advisable to repair or replace the wire to prevent corrosion of the underlying metal. Additionally, cleaning the wire with mild soap and water can help maintain its appearance and functionality over time.

The term 20 gauge refers to the thickness of the wire, as per the American Wire Gauge (AWG) standard. In this system, a lower gauge number indicates a thicker wire. Therefore, 20 gauge wire is relatively thin, with a diameter of approximately 0.032 inches (or 0.8128 mm). The wire is galvanized, meaning it has been coated with a layer of zinc to protect it from corrosion. This treatment significantly enhances the wire’s durability, making it suitable for various applications, especially in environments exposed to moisture, chemicals, and other corrosive elements.

2. Material Tomato cages are commonly made from a variety of materials, including metal, plastic, and wood. Metal cages, especially those made of galvanized steel, are durable and resistant to rust, making them a favorite choice for many gardeners. Plastic cages are lightweight and easy to move but may not provide the same level of support. Wooden cages, while aesthetically pleasing, can decay over time without proper treatment.

For 225mm wall ties, specific types like ladder ties or flat ties might be used, depending on the required strength and application. Ladder ties, for example, have a grid-like structure that provides enhanced resistance to lateral movements, which is particularly important in earthquake-prone areas.

In the field of architecture, Hexagonal wire netting is widely used in various aspects such as building enclosures, protective fences, and slope protection nets due to its excellent durability and flexibility. It not only builds a solid safety barrier for construction sites, effectively isolates the construction area, prevents unauthorized personnel from entering, and ensures construction safety and efficiency; At the same time, its unique structural design can withstand certain external impacts, protecting construction site facilities from damage. In addition, Hexagonal wire netting also has good customizability, and the size and strength can be adjusted according to specific needs to meet diverse building safety requirements.

Cavity ties are usually made of sturdy materials such as stainless steel or galvanized steel, ensuring they possess the necessary strength and resistance to corrosion. These ties are designed to span the cavity space between the two leaves of a wall, thus maintaining alignment and stability. Depending on the specific construction needs and environment, cavity ties can vary in length, shape, and configuration. The most common types include the horizontal, vertical, and angled cavity ties, each serving particular structural requirements.

Another significant property is its corrosion resistance, which is improved by the oil coating applied during the manufacturing process. This treatment helps prevent rust and deterioration, making black annealed steel wire suitable for outdoor applications, such as fencing and wire meshes. The wire's ability to maintain its integrity over time, even in harsh weather conditions, is a testament to its durability.

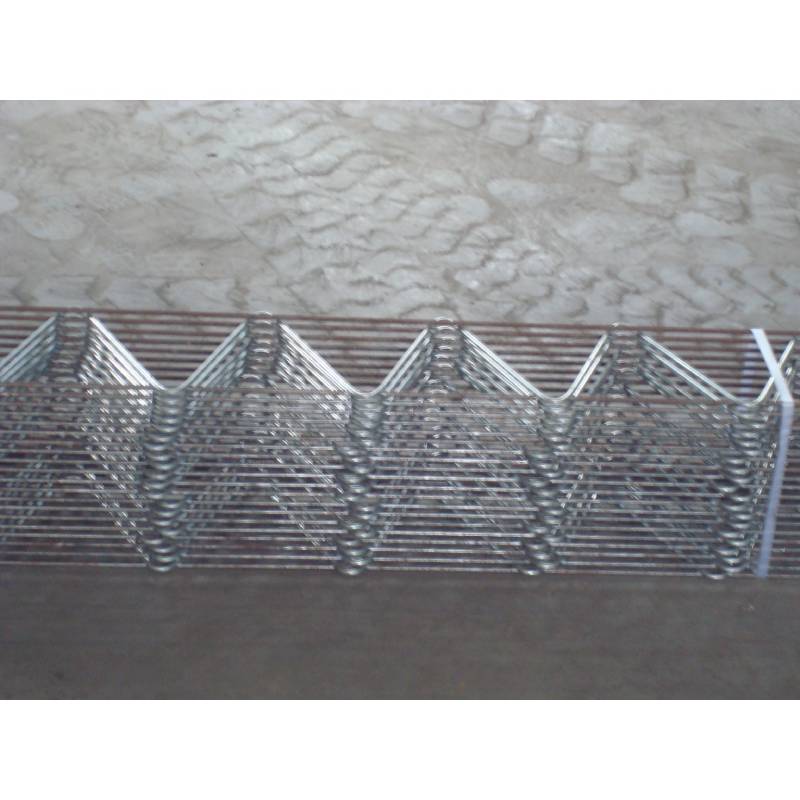

Compression springs play a crucial role in numerous mechanical applications, providing essential functionality across various industries. These coiled springs, designed to operate with a compressive load, are fundamental components within devices ranging from simple household items to complex machinery. An assortment of compression springs is a valuable resource for engineers, designers, and hobbyists alike, offering flexibility and efficiency in design and prototyping. In this article, we will explore the significance of compression spring assortments, their applications, and key considerations for selection.

Different types of coil springs with their unique performance and application characteristics can meet the diverse needs of all walks of life. Our coil wire springs rely on sophisticated technology, selected high-quality materials and rigorous quality inspection processes to create elastic components that are both safe and durable. From key components in precision instruments, to cushioning and supporting elements in automotive accessories, to convenient designs in household items, our springs are designed to support a wide range of products and equipment with their superior performance. Whether it's stability in extreme temperatures or durability in high frequency vibrations, our springs perform well to ensure your products perform at their best in any environment. By choosing our springs, you are choosing a guarantee of reliability and efficiency, giving your products an edge in the fierce market competition. If you have a need of coil wire spring, contact us now!

Additionally, wire fencing can be an effective solution against predators. By installing a secure fence, farmers can protect their livestock from threats such as coyotes, foxes, and stray dogs. The height and strength of specified types of wire fencing can be customized to address specific animal needs or regional wildlife threats, making it an adaptable choice for various farming situations.

Compression springs find applications in numerous industries, including automotive, aerospace, electronics, and consumer goods. In the automotive industry, they are integral to suspension systems, providing a smooth ride by absorbing shocks. In consumer electronics, they are used in keyboards and switches for tactile feedback. Additionally, they play a critical role in medical devices, appliances, and machinery, showcasing their versatility.

Moreover, wire mesh can enhance the aesthetic appeal of concrete walls. In decorative applications, such as in architectural designs that might expose concrete surfaces, the use of wire mesh allows for smoother finishes and can facilitate the application of various textures. Additionally, the mesh can serve as a substrate for various coatings and treatments, further enhancing the visual appeal of the finished product.

Continuous length extension springs are typically made from high-carbon steel or stainless steel, which provides the necessary resilience and durability. The material choice is critical as it influences the spring's tension, fatigue resistance, and overall performance. The design of these springs involves a series of coils that are wound tightly together, allowing them to stretch when a load is applied. The coiled structure provides a significant amount of stored energy, which can be released when the tension is removed.

Historically, walls have been a fundamental element of human civilization. From ancient forts to modern skyscrapers, walls protect, divide, and connect. Stone, as a building material, symbolizes durability and resilience. When used in structures, stone walls represent not only physical barriers but also a commitment to longevity and stability. Among the ancient Romans, for instance, stone walls were an essential part of their fortifications, reflecting the strength and authority of the empire. Over centuries, this has evolved into modern engineering practices where stone is often incorporated with other materials, showcasing the adaptability of these ties over time.

The operation of an expansion spring is based on Hooke’s Law, which states that the force exerted by a spring is proportional to its displacement. When an external force compresses the spring, it stores potential energy; this energy is released when the force is removed, causing the spring to return to its original shape. The spring's ability to withstand substantial loads depends on its material, diameter, coil thickness, and overall design.