Seal strips play a fundamental role in preventing water leakage, which is crucial for maintaining the cleanliness and safety of a bathroom environment. Poorly designed or fabricated seal strips can lead to water seepage, causing mold growth, structural damage, and an overall decline in the hygiene of the space. This makes CE certification even more critical for consumers, as it assures them that the seal strips they are buying have been tested and verified for effectiveness.

Weather strip seals, commonly referred to simply as weather stripping, are materials applied around door frames to block air leaks, prevent moisture intrusion, and inhibit dust and insects from entering your home. They come in various materials including foam, vinyl, rubber, and metal, each designed for specific applications and climates. A well-installed weather strip seal can drastically reduce heating and cooling costs by preventing conditioned air from escaping and outside air from entering.

Choosing the right manufacturer for strip and seal floors is vital for achieving the desired results. By focusing on quality, sustainability, and customer service, these manufacturers not only enhance the lifespan of flooring systems but also contribute positively to the environment. Whether you are a contractor, facility manager, or a homeowner, considering these factors will lead you to make informed decisions in your flooring projects. Investing in high-quality strip and seal flooring solutions is an investment in both beauty and functionality, ensuring that your floors remain stunning for years to come.

In the fast-paced world of manufacturing and supply chain management, Original Equipment Manufacturer (OEM) relationships play a crucial role in ensuring product quality and consistency. One often overlooked aspect of these partnerships is the importance of OEM letters, which serve as formal communications between manufacturers and their clients. In this article, we will explore what OEM letters are, their significance, and the best practices for drafting them.

Aluminum profiles are pre-defined cross-sectional shapes made from aluminum extrusions. These profiles come in a variety of shapes and sizes, including angles, channels, and tubes, which can be customized to meet specific requirements. The extrusion process involves forcing heated aluminum through a specially designed die, producing the desired shape. This method not only optimizes material use but also allows for intricate designs that can be tailored to a wide range of applications.

Weather strip foam seal products are an essential investment for anyone looking to improve their energy efficiency, comfort, and overall quality of their living or workspace. By understanding the various types available and their benefits, as well as following simple installation tips, you can significantly enhance your property's performance and sustainability. Whether you're a DIY enthusiast or a homeowner, these products can make a tangible difference in your energy consumption and comfort level.

Shower cubicle door seal strips serve a vital purpose in maintaining the integrity and hygiene of shower enclosures. They are designed to create a watertight seal at the edges of the shower doors, preventing water leakage that can lead to mold growth and damage to bathroom fixtures and flooring. Made from materials such as silicone, rubber, and PVC, these seal strips are praised for their flexibility, durability, and ease of installation.

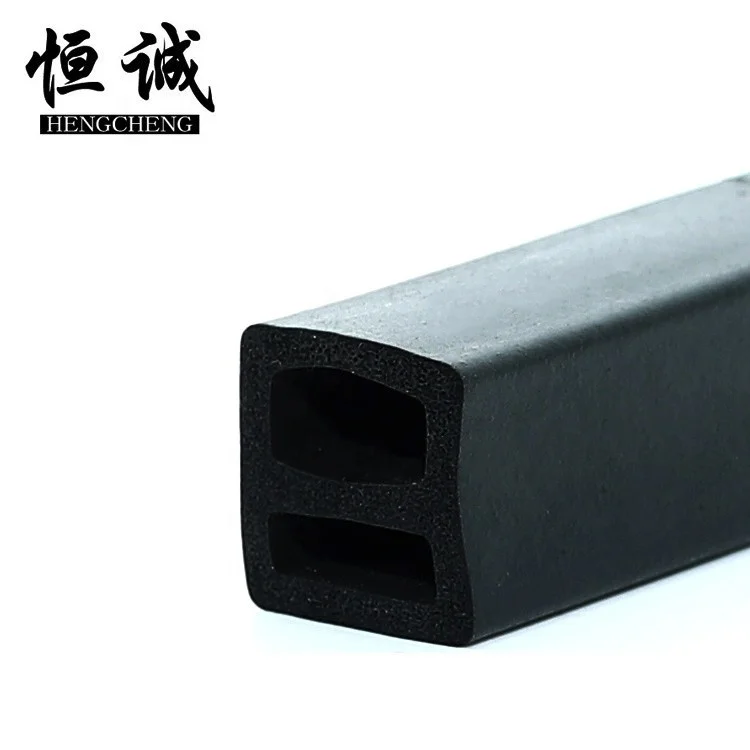

When selecting a thick rubber seal strip for a specific application, several factors should be considered, including the type of environment, the sealing requirements, and any regulatory standards that may apply. It's essential to choose a reputable company that specializes in rubber seal strip manufacturing, as they will provide products that meet high-quality standards and can offer advice on the best solutions for your needs.