temporary fence buy

-

10% 20-Gauge 2x4 Welded Wire for Reliable Fencing and Construction Applications

Understanding 10% Gauge 2x4 Welded Wire Applications and Benefits Welded wire mesh is a versatile ma...

-

Affordable Prices for Chicken Wire Mesh Options Available Online

Understanding the Price of Chicken Wire Mesh Chicken wire mesh is a versatile and widely used materi...

-

Choosing the Best 5 Gallon Bucket for Your Tomato Caging Needs

Enhancing Your Garden with a 5-Gallon Bucket Tomato Cage Gardening enthusiasts often look for innova...

-

5 chicken wire fencing

The Versatility of 5% Chicken Wire Fencing Chicken wire fencing, often referred to as poultry nettin...

-

Current Pricing Trends for 720 Wire Coil in the Market Today

Understanding the Price of 720 Wire Coils When it comes to the industrial manufacturing sector, wir...

-

Durable 6-Foot High Chain Link Fence Solutions for Enhanced Security and Property Protection

The Versatility and Benefits of 6% High Chain Link Fence In the world of fencing options, the 6% hig...

-

200x200 Post Caps - Durable and Stylish Solutions for Your Projects

Exploring the World of 200x200 Post Caps In the realm of construction and DIY projects, aesthetics...

-

70cm wide garden gate

The Versatility of a 70cm Wide Garden Gate A garden gate is not merely a functional item; it is an i...

-

Durable 3.5 Inch Post Caps for Enhanced Outdoor Deck and Fence Protection

The Versatility and Importance of 3.5 Inch Post Caps Post caps have long been an essential accessory...

-

Cost of Installing Six-Foot Chain Link Fencing for Your Property

When considering a six-foot chain link fence, one might be interested in understanding the costs inv...

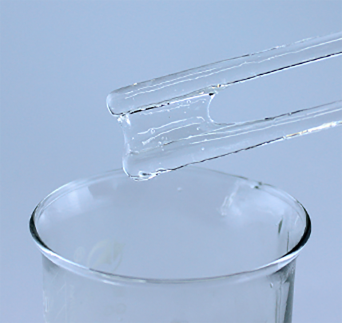

Its solubility in cold water and thermal gelation properties enable the design of drug delivery systems that respond to physiological conditions, ensuring targeted and sustained release of medication Its solubility in cold water and thermal gelation properties enable the design of drug delivery systems that respond to physiological conditions, ensuring targeted and sustained release of medication

Its solubility in cold water and thermal gelation properties enable the design of drug delivery systems that respond to physiological conditions, ensuring targeted and sustained release of medication Its solubility in cold water and thermal gelation properties enable the design of drug delivery systems that respond to physiological conditions, ensuring targeted and sustained release of medication Conversely, small-scale production may result in higher prices due to higher production costs per unit Conversely, small-scale production may result in higher prices due to higher production costs per unit

Conversely, small-scale production may result in higher prices due to higher production costs per unit Conversely, small-scale production may result in higher prices due to higher production costs per unit An ideal HPMC supplier should not only provide high-quality products but also offer technical assistance, helping clients understand the product's application, dosage recommendations, and troubleshoot any issues that may arise An ideal HPMC supplier should not only provide high-quality products but also offer technical assistance, helping clients understand the product's application, dosage recommendations, and troubleshoot any issues that may arise

An ideal HPMC supplier should not only provide high-quality products but also offer technical assistance, helping clients understand the product's application, dosage recommendations, and troubleshoot any issues that may arise An ideal HPMC supplier should not only provide high-quality products but also offer technical assistance, helping clients understand the product's application, dosage recommendations, and troubleshoot any issues that may arise HPMC is particularly effective at promoting disintegration in tablets containing drugs that are sensitive to moisture or heat HPMC is particularly effective at promoting disintegration in tablets containing drugs that are sensitive to moisture or heat

HPMC is particularly effective at promoting disintegration in tablets containing drugs that are sensitive to moisture or heat HPMC is particularly effective at promoting disintegration in tablets containing drugs that are sensitive to moisture or heat where to buy hydroxyethyl cellulose. It is commonly found in sauces, dressings, and other liquid foods where it helps to improve their consistency and prevent separation. HEC is also used in the preparation of ice creams and other frozen desserts, where it helps to create a smooth, creamy texture.

where to buy hydroxyethyl cellulose. It is commonly found in sauces, dressings, and other liquid foods where it helps to improve their consistency and prevent separation. HEC is also used in the preparation of ice creams and other frozen desserts, where it helps to create a smooth, creamy texture.