Rubber sealing strips are made from a variety of materials, including natural rubber, silicone, EPDM (ethylene propylene diene monomer), and polyurethane. Each type has its unique properties, making it suitable for different applications. For instance, EPDM is highly resistant to ozone and UV light, making it ideal for outdoor usage, while silicone sealing strips are known for their versatility in high-temperature environments. This diversity in materials allows exporters to cater to the specific needs of various industries.

In conclusion, OEM window glass seal strips are more than just simple components; they are essential elements that contribute to a vehicle's safety, performance, and aesthetic appeal. The benefits of using OEM parts far outweigh those of aftermarket options, including quality assurance, perfect fit, enhanced durability, safety features, and aesthetic consistency. As consumers grow increasingly aware of the importance of quality in automotive components, choosing OEM seal strips is a decision that reflects a commitment to excellence and reliability.

Investing in high-quality house door seal strips is a wise decision for homeowners looking to improve energy efficiency, protect against weather-related issues, prevent pests, and reduce noise levels. The benefits of a well-sealed door extend far beyond comfort, leading to significant cost savings and enhanced home security. By understanding the importance of these strips and taking the time to choose the right materials and ensure proper installation, homeowners can enjoy a more comfortable, efficient, and tranquil living environment. In today’s world, where energy efficiency and sustainability are more important than ever, high-quality door seal strips are a small yet impactful upgrade that can make a significant difference in the home.

Fire seal strips, also known as fire door seals or fire-rated seals, are specialized products designed to create a fire-resistant barrier between doors, walls, and other openings. Made from a variety of materials, including intumescent seals that expand when exposed to heat, these strips can withstand high temperatures and help contain fire and smoke within a designated area. This containment is vital during a fire, as it can provide occupants with precious time to evacuate and help firefighters effectively battle the blaze.

Automatic lifting sealing strips are specialized sealing solutions that function seamlessly in automated environments. They are typically used in machinery that requires high-speed and accurate sealing processes. These strips are designed to provide a tight seal, preventing contamination, leakage, and loss of freshness. Common applications include food packaging, pharmaceuticals, and other consumer goods that require durable and reliable sealing methods.

In today's world, where precision and quality are paramount, the significance of proper sealing solutions cannot be overstated. Among the various sealing options available, T-shaped rubber seal strips have emerged as a preferred choice across multiple sectors, including automotive, construction, and manufacturing. This article will explore the functionality, advantages, and applications of T-shaped rubber seal strips, shedding light on their essential role in ensuring durability and efficiency.

From a consumer perspective, 3D signage enhances the shopping experience. Well-designed signs provide critical information, such as directions, promotional offers, and brand messaging, in an engaging manner. When consumers feel a personal connection to a brand, often fostered by striking visual elements, they are more likely to develop brand loyalty. This emotional engagement can lead to increased sales and market share, making 3D signage a worthy investment for any business.

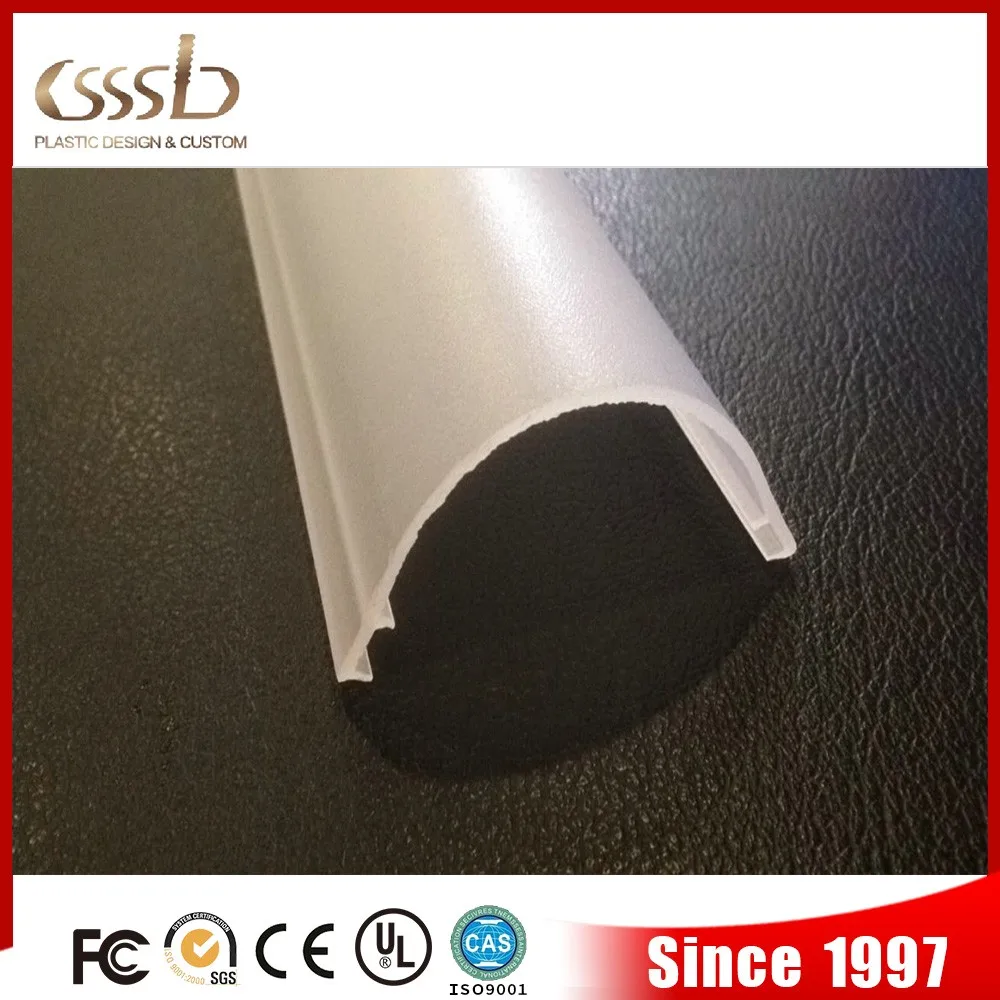

In various industries and applications, the significance of sealing solutions cannot be overstated. One of the most reliable and versatile options available today is the thick rubber seal strip. These strips are used in a wide array of environments, from residential to commercial and industrial settings, ensuring effective sealing against air, water, dust, and noise. As consumers and businesses seek reliable sealing solutions, understanding the benefits of thick rubber seal strips becomes essential.

Another significant aspect of high-quality stainless steel is its hygienic properties. The smooth, non-porous surface of stainless steel prevents the accumulation of bacteria and pathogens, making it a popular choice in environments where cleanliness is paramount. In hospitals, kitchens, and laboratories, stainless steel equipment can be easily cleaned and sanitized, reducing the risk of contamination and ensuring health and safety standards are maintained.

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer widely used in various applications due to its excellent strength, durability, and processing properties. The rise of 3D printing technology has significantly boosted the demand for ABS strips, commonly employed as filament materials in additive manufacturing processes. These strips are favored for their ability to produce robust and intricate designs, making them ideal for prototypes, automotive parts, and consumer goods.

In summary, shower base seal strips are essential components for maintaining a water-tight, hygienic, and comfortable bathing environment. By preventing water damage and enhancing overall hygiene, these strips serve a vital role in your bathroom. Whether you opt for silicone, vinyl, or rubber, ensuring a proper seal will lead to long-term savings and a more enjoyable shower experience. Don’t overlook this small yet mighty feature; invest in high-quality shower base seal strips and enjoy the peace of mind that comes with a well-maintained bathroom.

Moreover, neon LED tube lights are known for their durability. Unlike glass neon lights, which can be fragile and prone to breakage, LED technology is inherently more robust. LED tubes can withstand impacts and vibrations, making them suitable for various environments, including busy commercial spaces and outdoor applications. This durability translates into lower maintenance costs and longer product lifespans.