Beyond pharmaceuticals and construction, HPMC has made substantial inroads into the food industry. As a food additive, it serves as a stabilizer, emulsifier, and thickening agent, contributing to the texture and quality of products like sauces, dressings, and ice creams. HPMC Company recognizes the importance of food safety and quality, adhering strictly to food-grade standards and regulations.

Methyl Hydroxyethyl Cellulose (MHEC) is a remarkable polymer with a wide array of applications across multiple industries. Its unique properties make it an essential component in construction materials, pharmaceuticals, and personal care products. As research continues and technologies evolve, the versatility and benefits of MHEC are likely to expand even further, reinforcing its importance in various formulations and applications. The ongoing innovation around MHEC will undoubtedly lead to new and exciting uses, solidifying its role as a key ingredient in enhancing product performance and consumer satisfaction.

Moreover, the pH of the solution can significantly affect the solubility of HEC. Generally, HEC is stable across a wide pH range, which makes it versatile for various applications. However, extreme pH levels (either acidic or alkaline) can hydrolyze the ether linkages, leading to reduced molecular weight and, consequently, changes in viscosity and solubility profile.

Hydroxyethyl cellulose is extensively utilized in the construction industry as a thickener and water-retention agent in cement-based formulations such as mortars, plasters, and adhesives. In these applications, HEC helps improve the workability and application characteristics of construction materials, ensuring that they can be easily spread and adhered to surfaces. Moreover, its water-retention properties prevent drying too quickly, allowing for better adhesion and long-term durability of materials, which is crucial for construction projects.

Redispersible emulsion powder represents a vital component in modern construction and industrial applications, offering numerous advantages in terms of performance, ease of use, and versatility. Its unique properties make it indispensable for creating high-quality construction materials that meet the ever-evolving demands of the industry. As trends in sustainable building practices and advanced formulations continue to grow, the importance of REP will only become more pronounced, paving the way for innovative solutions in construction and beyond.

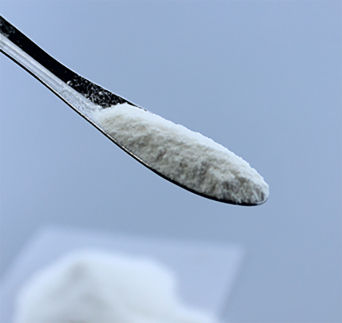

Hydroxypropyl methylcellulose (HPMC) is a cellulose-derived polymer that has garnered considerable attention in various sectors, including pharmaceuticals, food, and cosmetic industries. As a versatile ingredient, HPMC serves multiple purposes, ranging from acting as a thickener and emulsifier to functioning as a binder and stabilizer. Given its widespread use, a crucial question arises Is HPMC safe for consumption and application?

In the food industry, HPMC serves multiple functions ranging from a food additive to a stabilizer. It is often used in gluten-free baking as a binding agent, helping to enhance the texture and moisture retention of baked goods. HPMC improves the sensory qualities of food products, contributing to their mouthfeel and overall palatability. Moreover, it serves as an emulsifier in salad dressings and sauces, allowing for uniform distribution of ingredients, thus maintaining stability and preventing separation.

The solubility of HPMC in ethanol varies according to several factors, including the concentration of HPMC, the degree of substitution (DS), and the temperature of the solvent. Generally, HPMC with a higher degree of substitution tends to have increased solubility in ethanol. This is due to the greater presence of hydrophilic moieties that interact favorably with the ethanol molecules. Moreover, as the temperature of ethanol is raised, solubility trends upward, allowing for a greater amount of HPMC to dissolve.

The manufacturing process of hydroxyethyl cellulose is a complex yet well-defined procedure that transforms cellulose into a functional and versatile polymer. Through careful selection of raw materials, precise control of reaction conditions, and stringent quality assurance protocols, manufacturers can produce HEC that meets the high standards demanded by various industries. Its wide range of applications as a thickening agent, emulsifier, and stabilizer continues to drive its demand in the market, showcasing the importance of efficient and effective manufacturing processes in the chemical industry.