In conclusion, metal grid mesh panels serve a multitude of purposes across various sectors, from architecture and industry to landscaping and interior design. Their strength, versatility, and aesthetic appeal make them an attractive choice for many applications. As industries evolve and prioritize sustainability, the use of metal grid mesh panels is likely to increase, solidifying their place as a staple in modern design and construction practices. Whether enhancing a building's facade or providing safety in a manufacturing environment, these panels exemplify the innovative spirit of contemporary material use.

Additionally, gridwall displays are incredibly versatile. They can be used for a variety of product types, including clothing, accessories, toys, and even home goods. Retailers can customize their displays by incorporating various attachments and accessories such as shelves, baskets, and hooks, which allow for creative merchandising strategies. For example, a clothing store might display different sizes and styles of garments on gridwall hooks, while a toy store might use shelving to create visually appealing arrangements of products. This versatility ensures that retailers can adapt their displays to meet changing trends and seasonal shifts in inventory, creating a fresh shopping experience for customers.

In conclusion, the use of permanent formwork represents a significant advancement in construction practices. By streamlining processes, enhancing structural integrity, supporting sustainability, improving energy efficiency, and offering design flexibility, permanent formwork stands out as an efficient and effective choice for modern construction projects. As the industry continues to evolve, it is likely that more builders and developers will embrace this innovative approach, leading to safer, more durable, and environmentally friendly buildings for future generations.

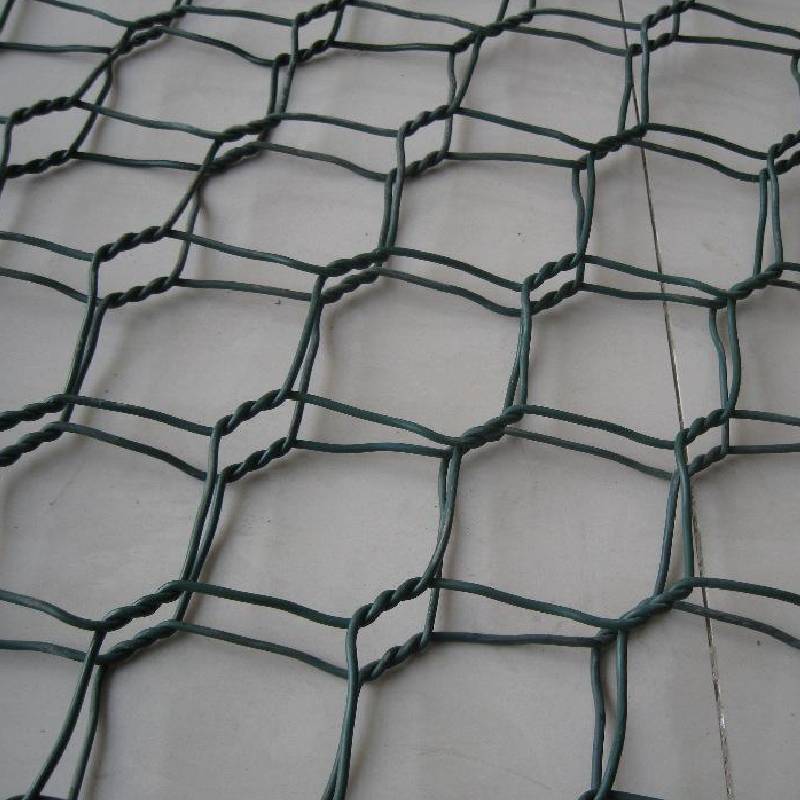

Galvanized metal wire is a versatile and essential material that finds applications in numerous industries, ranging from construction to agriculture, and even in everyday household uses. The process of galvanization involves coating iron or steel wire with a protective layer of zinc to prevent corrosion and rust, thus enhancing its durability and longevity. This article explores the characteristics, advantages, and diverse applications of galvanized metal wire.

In conclusion, iron plants are increasingly recognizing their role in supporting global sustainability. By embracing energy-efficient production methods, adopting the principles of the circular economy, leveraging technological innovations, and engaging with local communities, iron plants are transforming from traditional production facilities into modern, sustainable operations. This shift not only benefits the environment but also ensures that the industry can adapt to the challenges of the 21st century. As we move towards a more sustainable future, the contributions of iron plants will be vital in achieving the goals of reducing carbon emissions and promoting a circular economy.

Heavy-duty compression springs are typically manufactured from high-carbon steel, stainless steel, or other durable materials capable of enduring extreme loads and conditions. They are constructed in a tightly coiled manner, enabling them to compress and store energy when force is applied. The design of these springs often includes factors such as wire diameter, coil diameter, and free length to ensure optimal performance in their specific applications.

Tension springs with hooks are indispensable components in numerous mechanical applications, combining functionality with adaptability. From automotive systems to home appliances, these springs ensure that systems perform optimally by providing necessary tension and support. Understanding their characteristics and applications can aid engineers and designers in selecting the right components for their projects, ultimately enhancing performance and efficiency in various industries. As technology continues to advance, the design and functionality of tension springs will likely evolve, providing even more innovative solutions for the challenges faced in engineering and manufacturing.

One of the primary advantages of stainless steel garden wire is its corrosion resistance. Stainless steel is composed of iron, chromium, and often nickel, which work together to form a protective layer that prevents rust and degradation. This characteristic is particularly beneficial for outdoor use, where exposure to moisture, soil, and changing weather conditions can take a toll on other materials. Gardeners can rest assured that their stainless steel wire will remain intact and functional over time, even in the harshest of environments.

In conclusion, tiny coil springs, while small in size, have a significant impact across a variety of industries. Their unique characteristics make them essential in applications that require precision, reliability, and durability. As technology continues to advance, the demand for smaller, more efficient components will likely lead to further innovations in the design and production of tiny coil springs. Whether in electronics, medical devices, or automotive systems, these miniature components are undoubtedly a fundamental part of modern engineering that helps drive progress and innovation in countless fields.