UV water treatment utilizes ultraviolet light, specifically UV-C light, to inactivate microorganisms present in water. When water passes through a UV chamber, it is exposed to UV light, which penetrates the cells of bacteria, viruses, and other pathogens. This light disrupts the DNA and RNA of the microorganisms, preventing them from reproducing and rendering them harmless. Unlike chemical disinfection methods, which may leave residual chemicals in the treated water, UV treatment is a physical process that does not alter the chemical composition of the water.

In conclusion, filter vessels are indispensable components in many industrial processes, significantly influencing the quality of products and the efficiency of operations. As industries continue to evolve, the design and technology of filter vessels are also advancing, leading to more efficient, durable, and user-friendly options. By investing in high-quality filter vessels and embracing systematic maintenance practices, companies can enhance productivity, ensure compliance with regulations, and protect their assets from the negative impact of contamination. As such, understanding the importance of these vessels and prioritizing their role in industrial processes is key to achieving operational excellence in today's competitive market.

The maritime industry witnesses constant innovation, and one of the significant advancements has been the utilization of Fiber-Reinforced Plastic (FRP) in vessel construction. FRP vessels have gained popularity due to their lightweight, corrosion resistance, and longevity. Among these, the 1465 FRP vessel stands out, often dubbed a revolutionary boat in various marine applications. Understanding the pricing dynamics of 1465 FRP vessels is vital for potential buyers, industry stakeholders, and enthusiasts.

While each step of the GRP Podium is distinct, they are interconnected and should be approached holistically. Strong goals can help foster resilience, as having a clear purpose provides motivation during tough times. Likewise, recognizing progress can reinforce one’s resilience, creating a feedback loop that encourages perseverance. When individuals adopt a comprehensive approach to these steps, they enhance their likelihood of success.

1. Corrosion Resistance One of the most significant advantages of FRP sheet piling is its resistance to corrosion. In coastal and marine environments, traditional materials like steel are vulnerable to rust and deterioration due to saltwater exposure. FRP, on the other hand, is impervious to moisture, chemicals, and UV radiation, ensuring it remains structurally sound and visually appealing over its lifespan.

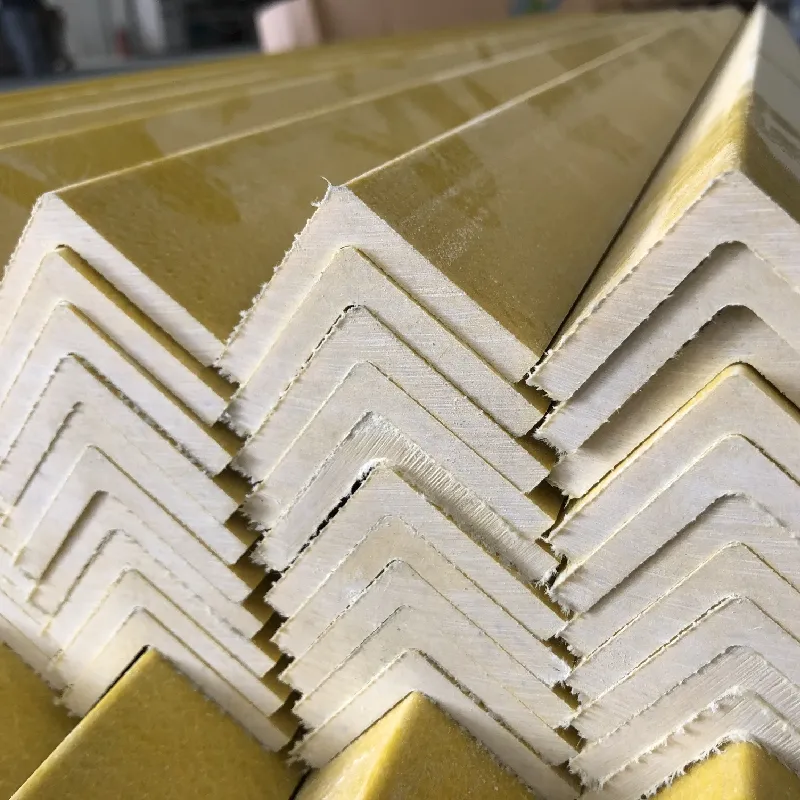

FRP, or Fiber Reinforced Polymer, is a composite material consisting of a polymer matrix reinforced with fibers. The most commonly used fibers are glass, carbon, and aramid, which are chosen for their high tensile strength and lightweight properties. The combination of these fibers with a polymer matrix results in a material that offers enhanced mechanical properties, making it suitable for various applications, particularly in demanding environments.

Rectangular metal water tanks are used in a variety of settings, making them incredibly versatile. They are commonly found in agricultural settings, where they serve as crucial components for irrigation systems, livestock watering, and even aquaculture operations. In urban environments, these tanks are used for municipal water storage, firefighting, and even in commercial buildings as part of their plumbing infrastructure.

Fiber water tanks also offer excellent versatility in terms of design and customization. They can be molded into a variety of shapes and sizes to meet specific requirements, whether for residential, commercial, or industrial use. Customization options include the incorporation of insulation layers, UV protection, and various fittings to match unique plumbing or environmental needs.