climbing plant support indoor

-

4 ft chain link fence

Chain Link Fence Ang Kahalagahan ng 4% na Paglago sa mga Proyekto ng Paghahardin at Pagsasaka Sa mga...

-

36 pouces de fil de fer barbelé

Tout sur le Poulailler avec du Fil à Poules de 36 pouces Dans le monde des aménagements extérieurs,...

-

8x6 fence panels

The Versatility of 8x6 Fence Panels An Essential Guide When it comes to redefining the boundaries of...

-

Building a Strong 8-Foot Square Fence Post for Your Outdoor Space

The Importance and Versatility of an 8% 20 ft Square Fence Post In the realm of outdoor design and l...

-

bulk chicken wire for sale

The Versatility of Bulk Chicken Wire A Practical Solution for Diverse Needs When it comes to buildin...

-

climbing plant supports for walls

Climbing Plant Supports for Walls Enhancing Beauty and Greenery Climbing plants have become a popula...

-

Creating Inviting Spaces with Stylish Garden Gate Posts for Your Outdoor Sanctuary

The Aesthetic Appeal of Garden Gate Posts When it comes to landscaping and gardening, the details of...

-

Choosing the Right Gate Hinges and Handles for Optimal Functionality and Aesthetic Appeal

The Importance of Quality Gate Hinges and Handles When it comes to securing and accessing your prope...

-

Creative Solutions for Supporting Spiral Plant Growth in Your Garden

The Benefits of Spiral Plant Support for Your Garden Gardening enthusiasts and home decor aficionado...

-

20mm Chicken Wire for Effective Animal Fencing and Garden Protection Solutions

The Versatility of 20mm Chicken Wire A Comprehensive Guide Chicken wire, also known as hex mesh, has...

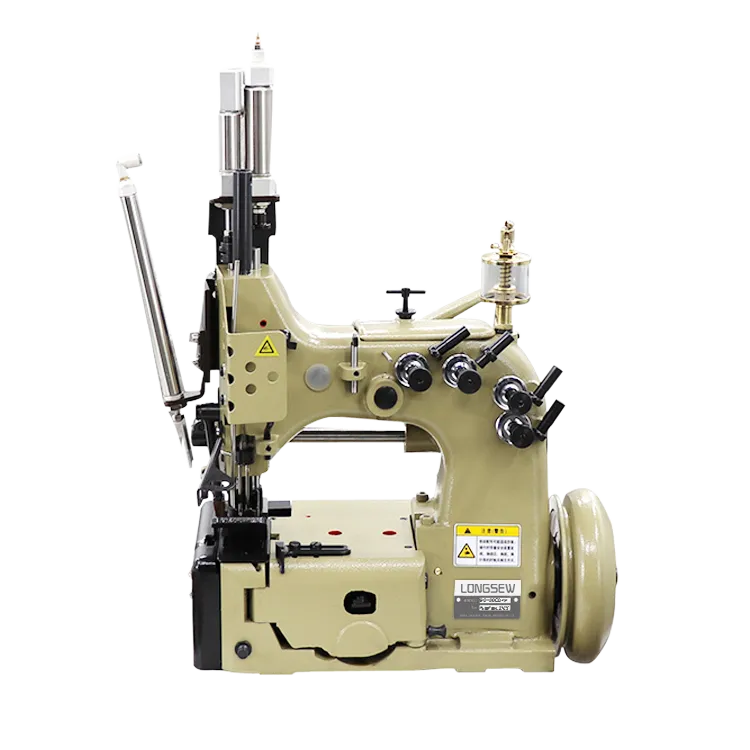

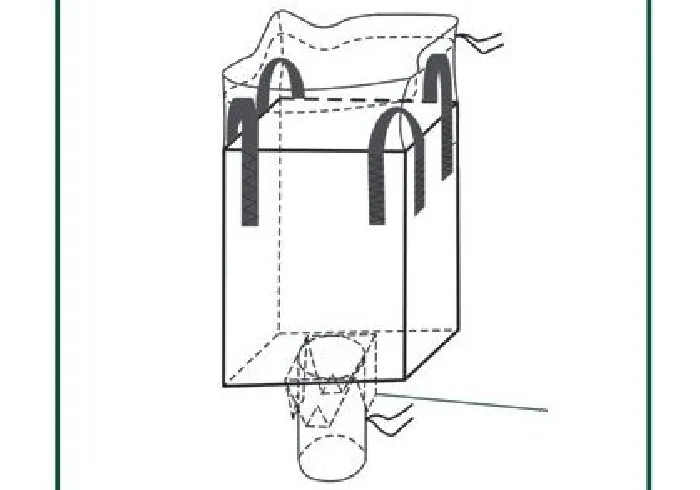

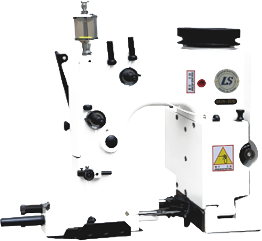

Other popular stitch patterns include straight stitch, decorative stitches, and even embroidery stitches Other popular stitch patterns include straight stitch, decorative stitches, and even embroidery stitches

Other popular stitch patterns include straight stitch, decorative stitches, and even embroidery stitches Other popular stitch patterns include straight stitch, decorative stitches, and even embroidery stitches