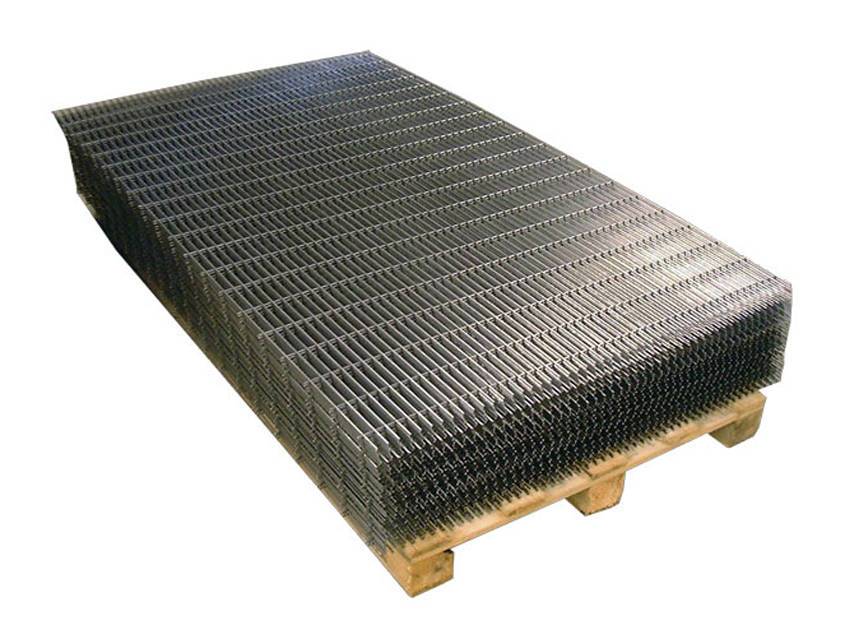

Welded wire fencing panels are a popular choice for a variety of applications, ranging from agricultural to industrial uses. Among the different types available, 6% welded wire fencing panels stand out for their strength, durability, and versatility. These panels, characterized by their 6% wire gauge, are specially designed to meet the demands of various environments while offering effective solutions for confinement, protection, and boundary setting.

In conclusion, small yard signs with stakes are more than just pieces of plastic or cardboard; they are tools for communication, creativity, and community engagement. Their visibility, customization options, and cost-effectiveness make them an attractive choice for personal and business use alike. Whether to celebrate a special occasion, promote local events, or encourage civic participation, these signs have solidified their place as a beloved medium of expression. As we continue to navigate a world filled with digital noise, the humble yard sign remains a trusted and effective way to share messages that matter.

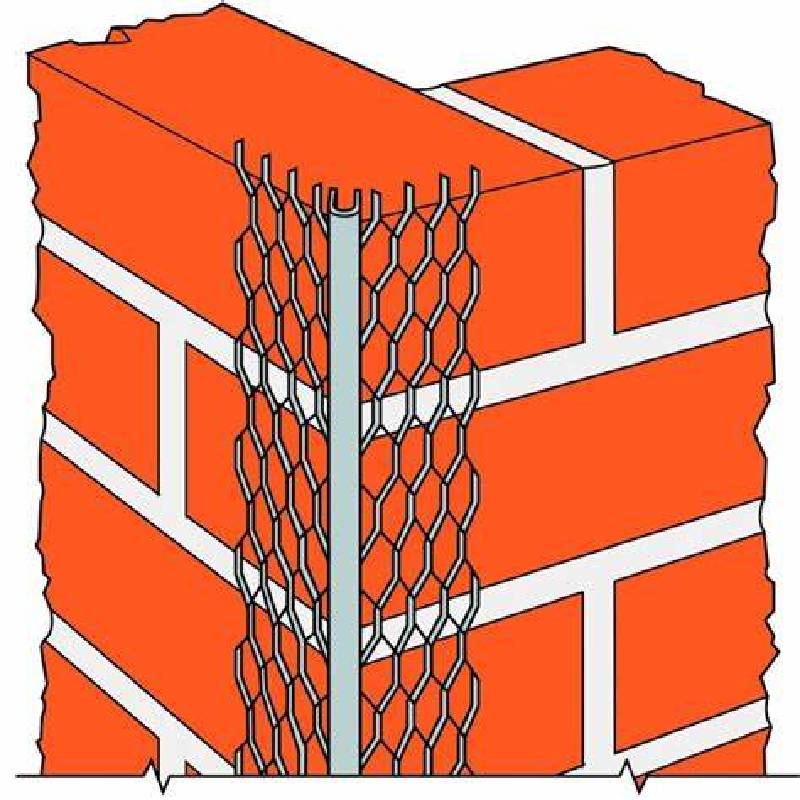

The importance of rib lath in construction cannot be overstated, and the choice of supplier can significantly influence the overall success of a project. By understanding the key factors in selecting rib lath suppliers—such as quality, product range, pricing, customer service, and sustainability—construction professionals can make informed decisions that contribute to the durability and aesthetic integrity of their builds. Collaborating with the right supplier not only facilitates efficient project completion but also fosters a partnership based on trust and mutual success in the ever-evolving construction industry. As the market continues to grow, staying informed about suppliers and their offerings will be essential for achieving excellence in construction.

One of the most notable advantages of welded wire fence panels is their strength. Constructed from high-quality steel wire, these panels are welded at each junction, providing a robust structure that can withstand heavy pressure and adverse weather conditions. Unlike traditional fencing options, such as wooden or barbed wire fences, welded wire does not warp, rust, or sag over time, ensuring that your fence remains effective and visually appealing for years to come.

Heavy-duty compression springs are integral components in many mechanical systems, providing the necessary force and resilience to support various applications. Understanding the properties and applications of these springs is crucial for engineers and manufacturers to ensure that they select the right type for their specific needs. As industries continue to evolve, ongoing advancements in materials and manufacturing processes will allow for the development of even more efficient and durable compression springs, further enhancing their functionality across diverse fields. Whether in automotive, aerospace, manufacturing, or construction, heavy-duty compression springs are essential in enabling innovation and progress in modern engineering solutions.

The core of PVC coated GI wire is galvanized iron wire, which undergoes a process of galvanization to prevent corrosion. Galvanization involves coating the iron wire with a layer of zinc, a technique that significantly enhances the wire’s resistance to rust and environmental factors. Once this protective layer is applied, a layer of Polyvinyl Chloride (PVC) is added, creating a strong, durable, and weather-resistant product. The combination of these two materials results in a wire that maintains flexibility while providing exceptional strength and resistance to wear and tear.

Welded wire mesh panels are a valuable resource across multiple industries, offering strength, durability, and versatility. Whether you need them for construction, fencing, agricultural use, or industrial applications, their cost-effective nature and ease of installation make them a preferred choice. With numerous options available on the market, finding the right welded wire mesh panels for your needs has never been easier. By understanding the features and benefits of these panels, you can make an informed decision that will serve you well for years to come.

The fundamental principle governing the behavior of a compressed spring is Hooke's Law, which states that the force exerted by a spring is directly proportional to its displacement, provided the material does not exceed its elastic limit. Mathematically, this is expressed as \(F = kx\), where \(F\) is the force exerted by the spring, \(k\) is the spring constant (a measure of the spring's stiffness), and \(x\) is the displacement from its neutral position. This relationship allows engineers to calculate the performance and specifications required for various applications.