As concerns about environmental sustainability continue to grow, fiberglass fence posts present an eco-friendly choice. Many fiberglass products are made from recycled materials, contributing to less waste and a reduced carbon footprint. Additionally, since fiberglass is long-lasting, it decreases the demand for new materials, promoting a more sustainable approach to fencing solutions.

In marine environments, where saltwater exposure is relentless, FRP grating platforms prove their worth by maintaining integrity and performance, making them ideal for docks, piers, and other coastal applications. Furthermore, in the oil and gas industry, where safety and material resilience are paramount, FRP solutions contribute to establishing secure working environments while adhering to stringent regulations.

To maximize the benefits of anti-slip treads, regular maintenance is necessary. Cleaning the treads to remove dirt, debris, and moisture can help maintain their effectiveness. Over time, wear and tear may necessitate replacement to ensure continued safety. It is advisable to periodically inspect the treads for signs of degradation, particularly in high-traffic areas.

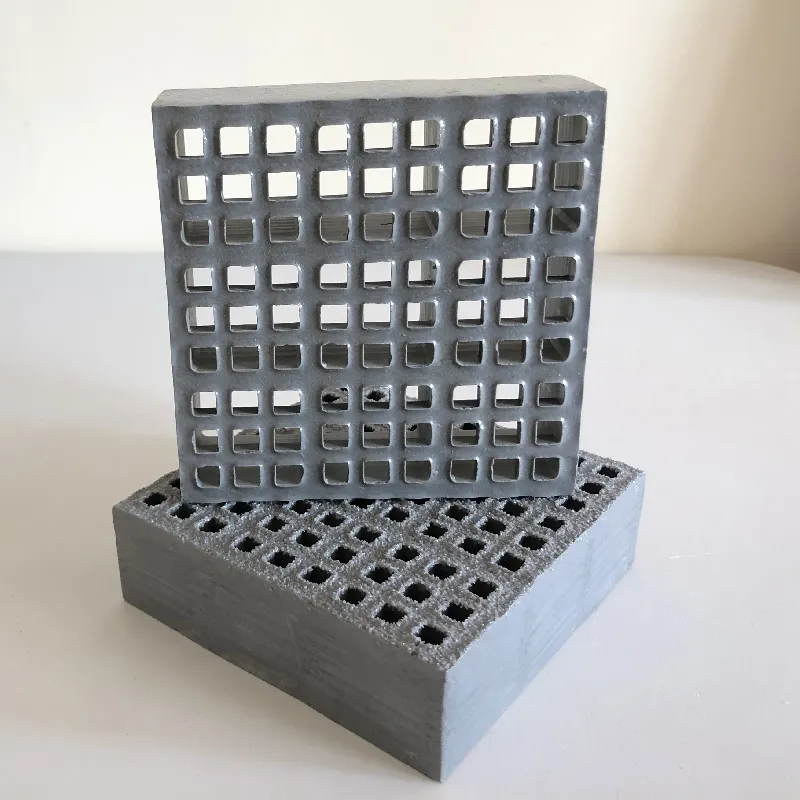

Fiber Reinforced Polymer (FRP) grating has emerged as a revolutionary material in various industrial applications due to its unique properties and advantages over traditional materials. Comprising a combination of fibers (such as glass, carbon, or aramid) within a polymer matrix, FRP grating offers an optimal answer to challenges posed by environmental conditions, mechanical stresses, and weight restrictions.

FRP rebar is composed of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. This unique combination results in a material that is both lightweight and exceptionally strong, making it an attractive alternative to traditional steel rebar. One of the most notable characteristics of FRP rebar is its high tensile strength-to-weight ratio, which allows for easier handling and installation on job sites. Unlike steel, which can corrode over time when exposed to moisture and chemicals, FRP rebar boasts excellent resistance to corrosion and environmental degradation, leading to extended service life and reduced maintenance costs.

Fiberglass rods are made from a composite material consisting of fine glass fibers embedded in a resin matrix. This combination results in a highly durable, lightweight, and non-conductive material that is resistant to corrosion, UV degradation, and extreme weather conditions. The inherent properties of fiberglass make it an excellent alternative to traditional materials, such as wood or metal, when constructing electric fences.

In conclusion, 38mm GRP grating is an exceptional choice for those seeking a strong, lightweight, and corrosion-resistant flooring solution. Its combination of safety features, ease of installation, and adaptability in various industries makes it an ideal material for modern construction needs. As industrial demands evolve, the use of advanced materials like GRP grating will undoubtedly play a vital role in ensuring safety and efficiency in many applications.

Stainless steel floor grating has emerged as a preferred choice in various industrial and architectural applications, thanks to its unique combination of durability, aesthetic appeal, and functional versatility. As environments become increasingly demanding, the need for reliable flooring solutions has never been more critical. This article explores the benefits and applications of stainless steel floor grating, shedding light on why it stands out in the world of construction and design.

Additionally, GRP open mesh grating is highly customizable. It can be manufactured in various panel sizes, thicknesses, and mesh configurations to meet specific project requirements. The material can be easily cut and shaped on-site without the need for heavy machinery, which adds to its versatility. This adaptability allows for the design of complex shapes and fitting in confined spaces, which can be challenging with more rigid materials.

At its core, mesh grating consists of a series of closely spaced openings or lines that create a periodic pattern. These patterns can be designed in various dimensions and materials, depending on their intended application. The principal function of mesh grating is to diffract light or sound waves, thereby altering their direction and intensity based on the specific requirements of a project. The spacing between the mesh lines, or the dimensions of the openings, plays a crucial role in determining the wavelength of light or sound that can be effectively manipulated.

FRP pultruded sections are produced using a specialized manufacturing process known as pultrusion. In this process, fibers (often glass, carbon, or aramid) are pulled through a resin bath and then through a heated die, where they are shaped into continuous profiles. The result is a highly uniform and strong product that can be manufactured in various shapes and sizes, including beams, rods, and plates.