There are various types of water filtration systems available, including activated carbon filters, reverse osmosis systems, and UV purifiers. Activated carbon filters are particularly popular for their ability to remove chlorine and improve taste and odor, while reverse osmosis systems provide a more comprehensive option, effectively filtering out a wide range of contaminants through a semi-permeable membrane.

In conclusion, aluminum bar grating emerges as a vital material across diverse sectors, fueled by its strength, versatility, and corrosion resistance. Its myriad applications—from industrial environments to commercial settings—underscore its significance in modern infrastructure. As industries continue to evolve, the demand for durable, lightweight, and cost-effective solutions like aluminum bar grating will only increase, paving the way for enhanced safety and efficiency in various fields. By choosing aluminum bar grating, businesses invest in a product that promotes safety, sustainability, and longevity, making it an optimal choice for future projects.

In summary, fiberglass stairs represent a modern solution that combines strength, low maintenance, aesthetic versatility, safety, and eco-friendliness. Whether for residential properties, commercial buildings, or outdoor settings, fiberglass stairs are a remarkable choice that meets various needs and preferences. As homeowners and builders continue to seek durable and stylish solutions for their projects, fiberglass stairs are poised to become an even more prominent feature in the world of construction and design. Embracing this innovative material can lead to buildings that are not only beautiful but also built to last.

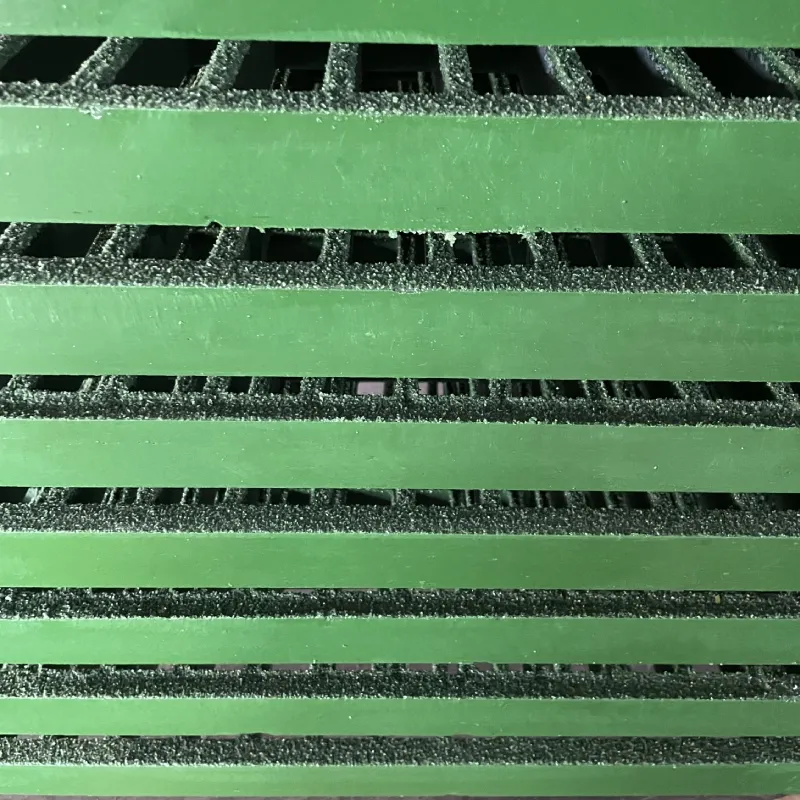

Glass Reinforced Plastic, commonly known as fiberglass, is a composite material made by combining glass fibers with a resin. The resulting product is strong, corrosion-resistant, and lightweight, making it ideal for various applications. GRP grating comes in different thicknesses and sizes, with the 38mm specification being one of the most sought after for heavy-duty applications.

Heavy duty bar grating is an indispensable component in various industrial applications, renowned for its strength, durability, and versatility. This type of grating is typically composed of thick metal bars that are welded or press-locked together, creating an exceedingly robust framework capable of bearing heavy loads. Its applications range from flooring systems and walkways to platform supports and drainage covers, making it a critical element in sectors such as manufacturing, construction, and infrastructure.

Statistics show that slips and falls are one of the leading causes of injuries, particularly among the elderly and children. Wet or dirty stairs can be deceptively hazardous, making it essential for homeowners and business operators to take proactive measures. Anti-slip stair treads significantly reduce the risk of accidents by enhancing grip, regardless of the environmental conditions. In commercial settings, ensuring safe stair navigation is not only a matter of employee well-being but also a legal obligation. Businesses can be held liable for accidents caused by negligent safety measures, making the installation of anti-slip tread an essential investment.

In summary, understanding the pricing of fibreglass grating involves considering various factors, including the type of grating, thickness, resin type, surface finish, purchasing quantity, and prevailing market trends. By carefully evaluating these elements, customers can make more informed decisions, ensuring they select the right product for their needs at a competitive price. As with any significant investment, thorough research and shopping around are essential to securing the best value in fibreglass grating purchases.

In conclusion, bar grating is a highly functional and adaptable solution for various industrial, commercial, and architectural applications. With a range of options available for sale, selecting the right type of bar grating can enhance safety, efficiency, and aesthetics in any project. Whether you are a contractor, architect, or facility manager, understanding the benefits and features of bar grating is crucial in making informed purchasing decisions.

In recent years, the construction industry has seen significant advancements in material science, and one of the most notable innovations is the use of Fiber Reinforced Polymer (FRP) composites in structural applications. With properties that enhance performance, durability, and versatility, structural FRP is becoming a preferred choice for engineers and architects looking to push the boundaries of traditional construction methods.

In summary, sectional tanks offer a flexible, cost-effective, and efficient solution for water storage needs in various applications. Their modular design, ease of maintenance, and customizability make them an attractive choice for many homeowners, businesses, and industries. By understanding their features and benefits, as well as the importance of proper installation and maintenance, users can take full advantage of what sectional tanks have to offer, ensuring reliable and sustainable access to stored water.

The versatility of stainless steel floor grating makes it suitable for various applications across multiple industries. In commercial settings, it is widely used in restaurant kitchens, where heavy equipment and frequent cleaning are part of daily operations. In industrial environments, it proves indispensable in power plants, oil refineries, and sewage treatment facilities, where durability and resistance to harsh conditions are needed. Additionally, stainless steel grating is a popular choice for architectural applications, providing a modern aesthetic in walkways, bridges, and balconies.

In today's construction and industrial sectors, the choice of materials is crucial for ensuring durability, safety, and functionality. One innovative solution that has gained popularity in various applications is plastic floor grating. This article explores the benefits of plastic floor grating, its applications, and why it is becoming the material of choice for many businesses.

In conclusion, FRP rebar manufacturers are playing an increasingly important role in modern construction practices. By providing innovative and versatile materials, they enable the industry to enhance durability, reduce corrosion-related issues, and support sustainable building practices. As the demand for resilient infrastructure continues to rise, the contributions of these manufacturers will be pivotal in shaping the future of construction, ultimately leading to structures that are not only strong and durable but also environmentally responsible.