garden gate supplier

-

Building a Square Fence with Posts A Complete Guide to Installation and Design Ideas

The Square Fence Post A Multifaceted Symbol of Strength and Stability When we think of a square fenc...

-

Choosing the Best 1 Percent Round Fence Posts for Your Outdoor Project

The Role of 1% 2% Round Fence Posts in Modern Agriculture In the world of agriculture and livestock...

-

2 3 8 metal fence post

The Significance of Metal Fence Posts A Deeper Look into 2%, 3%, and 8% Options When planning to ins...

-

Durable 4-inch by 4-inch Welded Wire Fencing for Effective Livestock and Garden Protection

The Versatility and Utility of 4 x 4 Welded Wire Fencing When it comes to enclosures, boundaries, an...

-

A solid brass cylinder is a durable and sturdy object.

The Timeless Elegance of Solid Brass Cylinders In the realm of architectural hardware and design el...

-

7ft chicken wire

The Versatility and Appeal of 7ft Chicken Wire In the realm of construction and gardening, few mater...

-

4インチx 4インチ溶接ワイヤフェンス。

4インチ x 4インチの溶接ワイヤーフェンスについて 4インチ x 4インチの溶接ワイヤーフェンスは、様々な用途に使用される非常に実用的で耐久性のあるフェンスです。このタイプのフェンスは、園芸、農業、...

-

chicken wire 4 feet high

The Versatility and Practicality of 4-Foot High Chicken Wire When it comes to managing backyard poul...

-

Discover Innovative Chicken Mesh Solutions for Poultry Farming

The Versatility of Chicken Mesh An Essential in Poultry Farming and Beyond When it comes to poultry...

-

6 inch deck post caps

The Importance of 6-Inch Deck Post Caps Deck post caps are a crucial yet often overlooked element in...

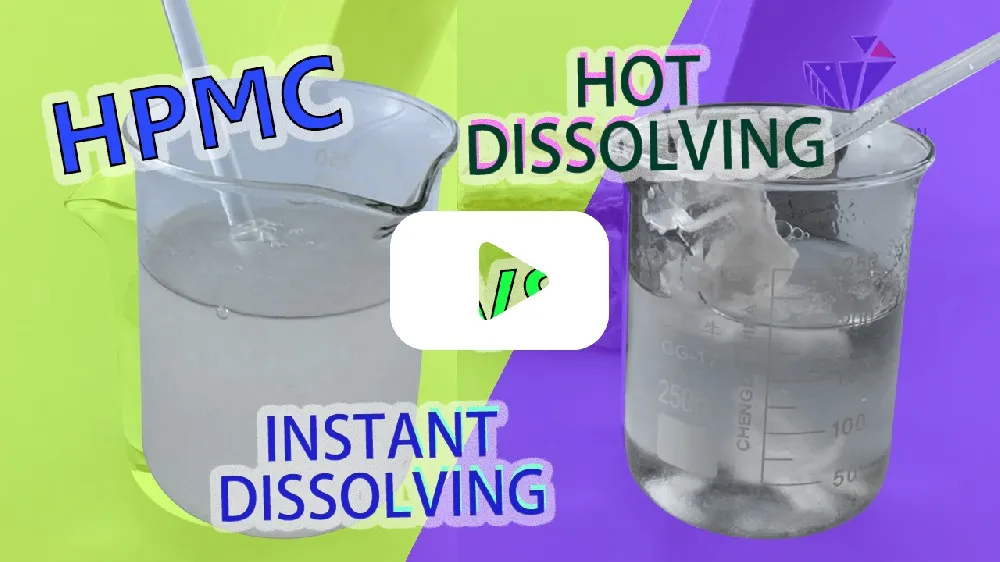

In the construction industry, it is commonly used in mortar, plasters, and tile adhesives, enhancing their workability, reducing water demand, and improving their setting time In the construction industry, it is commonly used in mortar, plasters, and tile adhesives, enhancing their workability, reducing water demand, and improving their setting time

In the construction industry, it is commonly used in mortar, plasters, and tile adhesives, enhancing their workability, reducing water demand, and improving their setting time In the construction industry, it is commonly used in mortar, plasters, and tile adhesives, enhancing their workability, reducing water demand, and improving their setting time Some major players include companies like Wacker Chemie AG, BASF SE, DOW Chemical Company, and AkzoNobel NV, known for their innovative solutions and commitment to sustainability Some major players include companies like Wacker Chemie AG, BASF SE, DOW Chemical Company, and AkzoNobel NV, known for their innovative solutions and commitment to sustainability

Some major players include companies like Wacker Chemie AG, BASF SE, DOW Chemical Company, and AkzoNobel NV, known for their innovative solutions and commitment to sustainability Some major players include companies like Wacker Chemie AG, BASF SE, DOW Chemical Company, and AkzoNobel NV, known for their innovative solutions and commitment to sustainability

This leads to more durable and consistent structures This leads to more durable and consistent structures

This leads to more durable and consistent structures This leads to more durable and consistent structures These modifications alter the properties of cellulose, imparting it with water-solubility and other desirable characteristics These modifications alter the properties of cellulose, imparting it with water-solubility and other desirable characteristics

These modifications alter the properties of cellulose, imparting it with water-solubility and other desirable characteristics These modifications alter the properties of cellulose, imparting it with water-solubility and other desirable characteristics