The factories producing 3D high polymer ABS strips play a crucial role in the advancement of 3D printing technology. Through a meticulous manufacturing process and stringent quality control measures, these facilities ensure that they deliver high-quality materials to a market that increasingly relies on durable, versatile, and efficient solutions. As the 3D printing landscape continues to evolve, so too will the innovations in polymer-based materials, paving the way for endless creative possibilities.

These seals serve multiple purposes. Beyond preventing drafts and conserving energy, they also help in soundproofing a space. By minimizing gaps, they reduce noise infiltration, thus creating a more peaceful environment within homes and offices. Additionally, they protect against moisture intrusion, helping to prevent mold and mildew buildup, which can be detrimental to indoor air quality.

Another advantage of transparent rubber is its excellent weather resistance. Many industries face challenges from harsh environmental conditions, including UV exposure, moisture, and extreme temperatures. Transparent rubber's resistance to these elements makes it an ideal choice for outdoor applications, including signage, automotive parts, and outdoor equipment. Products made from transparent rubber are not only durable but also retain their aesthetic appeal over time, reducing the need for frequent replacements.

The most commonly used grades of stainless steel for channel letters are 304 and 316. Grade 304 is often chosen for its excellent corrosion resistance and good formability, making it suitable for a wide range of applications. In contrast, grade 316, which contains molybdenum, offers enhanced resistance to pitting in chloride environments, making it ideal for coastal areas or regions with high salt exposure.

In today's fast-paced industrial landscape, the demand for reliable and effective sealing solutions has never been higher. High-quality rubber sealing strips are becoming indispensable in a variety of sectors, including automotive, construction, aerospace, and manufacturing. These strips play a crucial role in providing durability, enhancing performance, and ensuring safety across numerous applications.

Thick rubber seal strip exporters are increasingly vital to the global supply chain, facilitating the growth of various industries by providing essential sealing solutions. As the demand for these products continues to grow, driven by changing market dynamics and an emphasis on sustainability, exporters must adapt to stay competitive. By focusing on innovation, quality, and customer satisfaction, they can navigate challenges and capitalize on emerging opportunities in this thriving market.

When selecting a weather strip seal manufacturer, consider factors such as reputation, product range, and customer support. Established manufacturers with a history of quality and reliability often provide the best options. Additionally, they may offer custom solutions tailored to specific project needs, which can be a significant advantage for contractors and builders.

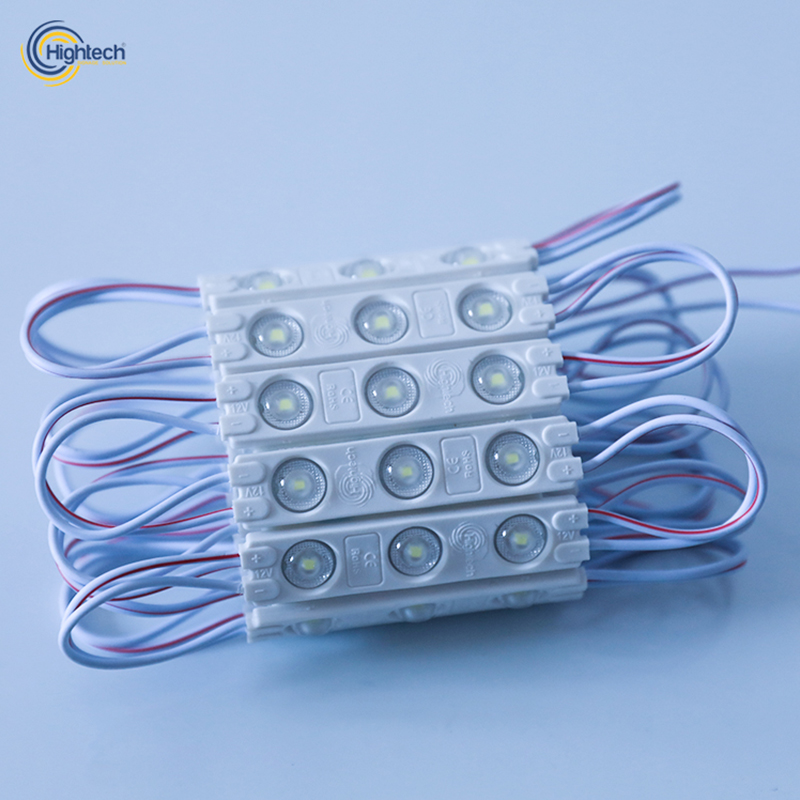

The technological advancements behind advertising light boxes are notable, with many suppliers now offering LED lighting options. LED lights are energy-efficient, durable, and provide bright illumination, enhancing the visibility of the displayed messages. Coupled with TPE edge frames, these light boxes can create stunning visual displays that grab attention without incurring excessive energy costs. This synergy not only promotes your brand but also aligns with sustainable practices, resonating well with environmentally conscious consumers.

2. Weatherstripping There are various types of weatherstripping, including V-strip, felt, and tubular rubber or vinyl. V-strip is particularly effective for sealing the edges of doors, while tubular rubber or vinyl provides excellent durability and insulation against cold drafts. Felt weatherstripping can serve as a budget-friendly option, but it typically offers less insulation over time.

With increasing global awareness surrounding environmental issues, the sustainability of materials is a critical consideration for businesses. Aluminum is one of the most recyclable materials available, and using single edge aluminum can lead to reduced waste production. By purchasing wholesale, companies are positioning themselves as environmentally conscious entities, appealing to customers who prioritize sustainability. Additionally, the lightweight nature of aluminum contributes to lower transportation emissions when compared to heavier materials.