In the pharmaceutical industry, HPMC plays an essential role as a film-forming agent and a thickener. It is widely utilized in the production of tablet formulations, where it aids in controlling the release of active ingredients. HPMC can create a hydrophilic matrix that allows for sustained or controlled release, which is crucial in designing formulations that require a gradual delivery of drugs. Moreover, HPMC is often employed in ophthalmic preparations due to its excellent viscosity and mucoadhesive properties, enhancing the bioavailability of eye medications.

In summary, China's HPMC factories are instrumental in producing one of the most versatile additives used across various industries worldwide. With advanced production processes and a commitment to quality, these factories are not only meeting the growing domestic demands but are also contributing significantly to the global supply chain. As industries continue to evolve and expand, the role of HPMC, and consequently the factories that produce it, will undoubtedly grow in importance. Moving forward, innovations in production techniques and sustainability practices will shape the future of HPMC manufacturing, reinforcing China’s position as a leading supplier in the global market.

In the food industry, HPMC is used as a thickener, emulsifier, and stabilizer in various products, such as sauces, dressings, and ice cream. It is also used as a coating agent for confectionery products and as a bulking agent in low-calorie foods.

In conclusion, Hydroxypropyl Methylcellulose (HPMC) is a multifaceted compound that plays a crucial role in numerous industries, ranging from pharmaceuticals to food production and construction. Its unique properties, such as solubility, film-forming capabilities, and thickening effects, provide significant benefits that enhance both product performance and consumer experience. As demand for sustainable and efficient materials continues to rise, HPMC is likely to see even broader applications and innovations in the future.

In summary, Hydroxypropyl Methyl Cellulose (HPMC) is a versatile and widely used polymer with applications spanning multiple industries. Its unique properties, such as thickening, emulsifying, and gel-forming capabilities, contribute to its effectiveness in pharmaceuticals, food, construction, and personal care products. With its safety profile and environmental compatibility, HPMC continues to be a crucial ingredient in modern industrial applications. As industries evolve and seek sustainable alternatives, compounds like HPMC will likely play an increasingly significant role in meeting these demands while ensuring quality and performance.

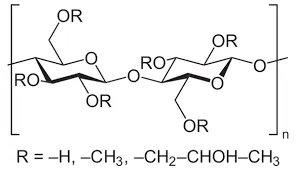

HPMC is derived from natural cellulose, which undergoes a series of chemical modifications to enhance its solubility and functionality. The number 4000 in HPMC 4000 refers to its viscosity, which is measured in centipoise (cP). This specific grade of HPMC typically has a viscosity range of 3000 to 5000 cP when diluted in water, making it a mid-range thickening agent. The unique combination of hydroxypropyl and methyl groups in HPMC imparts various characteristics such as film-forming ability, thermal stability, and a non-ionic nature, allowing it to interact effectively with a range of substances.

Methyl Hydroxyethyl Cellulose (MHEC) is a prominent cellulose derivative known for its versatility and wide range of applications across various industries. Particularly in China, MHEC has garnered significant attention owing to its useful properties such as thickening, binding, and emulsifying capabilities. As the demand for eco-friendly materials increases, MHEC has become a choice ingredient in many formulations, promoting sustainability without compromising performance.

One common concern is that it is found in non-food products - paint, eye drops, medicine (again, as a stabiliser). For the record, so is water. Like water, HPMC's existence in non-food products doesn't automatically discount it from being used in perfectly safe, edible products. Crucially, it has been approved as a food additive by both the EU and the FDA.

HPMC plays a vital role in the cosmetic and personal care industry, where it is used in formulating various products such as shampoos, lotions, creams, and makeup. Its thickening and emulsifying properties help to stabilize formulations, providing the desired consistency and texture. Additionally, HPMC acts as a film-forming agent, enhancing the spreadability and adherence of products on the skin or hair.

In summary, the glass transition temperature of hydroxypropyl methylcellulose is a crucial property that affects its suitability for various applications. By understanding the factors that influence Tg, such as the degree of substitution, molecular weight, and the presence of additives, manufacturers can tailor HPMC formulations to meet specific performance criteria. Whether in pharmaceuticals, food, or construction, having a deep understanding of Tg enables the development of more effective and reliable products. As research continues in this area, we can expect advancements that enhance the versatility and functionality of HPMC across different industries.

One of the more surprising potential side effects is the possible impact of HPMC on weight. As a thickening agent and bulking agent, it can create a feeling of fullness, which might be beneficial for weight management. However, in some cases, this may lead to unintentional weight loss if individuals consume less food overall due to prolonged satiety. While weight control can be advantageous, sudden changes in body weight can be concerning and may warrant consultation with a healthcare professional, especially in long-term users.

Cement bonding additives are specifically formulated to improve the bonding properties between cement and other materials, such as aggregates and reinforcement bars. The addition of bonding agents can enhance the overall performance of cementitious mixtures by increasing their workability, durability, and resistance to various environmental factors. These additives can be organic or inorganic substances, including polymers, latex, or specially designed chemical compounds.