steel wire rope tensioner

-

Cena siatki na kurczaka i jej wpływ na rynek mięsa

price of chicken mesh ....

-

Compact 800mm Garden Gate for Enhanced Outdoor Aesthetics and Security Solutions

The Charm and Utility of an 800mm Garden Gate When it comes to designing your outdoor space, the ent...

-

8-foot tall chain link fence options for security and durability in your outdoor space

The Importance of an 8-Foot Tall Chain Link Fence When it comes to enhancing security and privacy in...

-

Choosing the Best Support Options for Your Orchid Flower Plants and Their Growth Needs

The Art of Supporting Orchid Flowers with Stakes Orchids, with their exotic beauty and diverse varie...

-

Choosing the Right 4x6 Fence Post for Your Outdoor Project

The Importance of 4x6 Fence Posts in Modern Fencing Solutions When it comes to building a robust and...

-

Creative Ways to Enhance Your Garden with Stylish Fence Posts and Design Ideas

The Importance of Garden Fence Posts in Landscaping When it comes to creating a beautiful and functi...

-

Dikke gelaste draadgaas toepassingen en voordelen voor verschillende industrieën

Heavy Gauge Welded Wire Mesh Een Duurzame Oplossing voor Divers gebruik Heavy gauge welded wire mesh...

-

6x8 chain link gate

The Versatility and Benefits of a 6x8 Chain Link Gate When it comes to securing residential and comm...

-

5ft welded wire

The Versatility and Benefits of 5ft Welded Wire Fencing Welded wire fencing has become an essential...

-

chicken wire 48 inch

The Versatility of Chicken Wire Exploring its Uses and Benefits When we think about chicken wire, im...

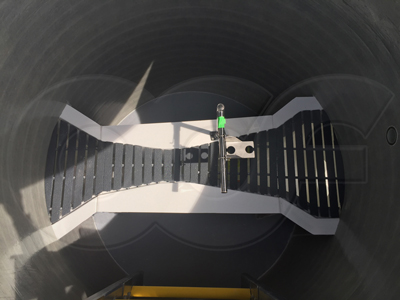

Additionally, fiberglass tanks can be equipped with various accessories, such as pumps, valves, and level indicators, to improve their functionality and efficiency Additionally, fiberglass tanks can be equipped with various accessories, such as pumps, valves, and level indicators, to improve their functionality and efficiency

Additionally, fiberglass tanks can be equipped with various accessories, such as pumps, valves, and level indicators, to improve their functionality and efficiency Additionally, fiberglass tanks can be equipped with various accessories, such as pumps, valves, and level indicators, to improve their functionality and efficiency Another major benefit of FRP mining equipment is its durability. Fiberglass is inherently resistant to corrosion, rust, and chemicals, making it an ideal material for use in harsh mining environments. This durability ensures that FRP equipment has a longer lifespan than traditional metal equipment, resulting in cost savings for mining companies in the long run

Another major benefit of FRP mining equipment is its durability. Fiberglass is inherently resistant to corrosion, rust, and chemicals, making it an ideal material for use in harsh mining environments. This durability ensures that FRP equipment has a longer lifespan than traditional metal equipment, resulting in cost savings for mining companies in the long run