pvc electrical tape suppliers. Look for suppliers that have a history of providing high-quality products and excellent customer service. You can also check online reviews and testimonials to get an idea of the supplier's reputation.

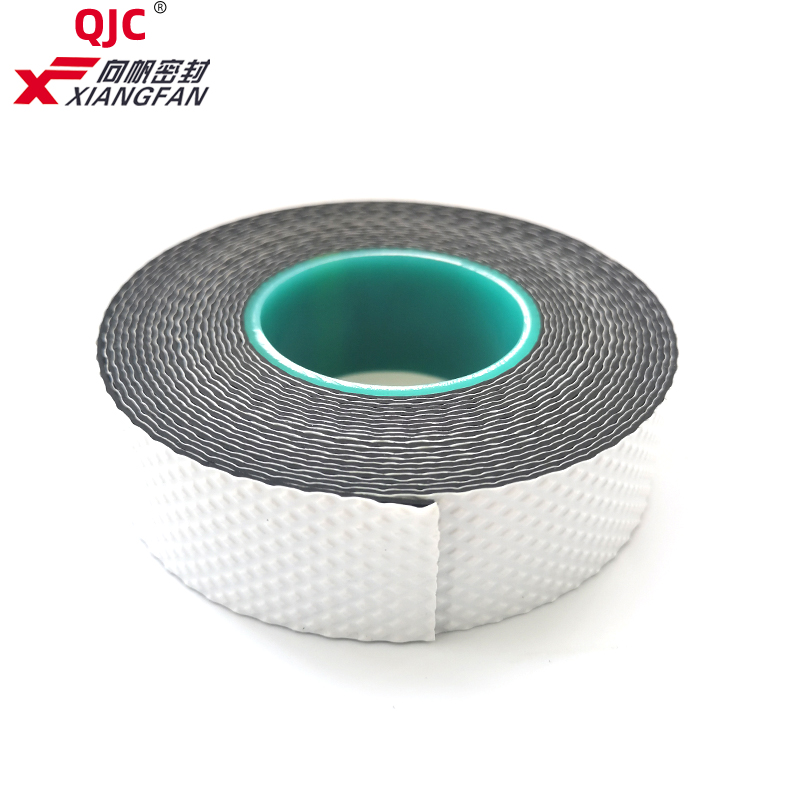

Of all the tapes available in today’s market, self-amalgamating tape is quite unique. Our guide looks at what it is, how it works, and how you can use it.

3. Simplified Installation The tape's flexibility and ease of use make it a convenient choice for installing and organizing wires and cables in tight spaces. Furthermore, blue insulation tape is also very easy to apply and remove, making it a convenient choice for many professionals. The adhesive backing of the tape sticks well to a variety of surfaces, ensuring a secure hold without leaving any residue behind when removed. This makes it ideal for temporary repairs or quick fixes that may need to be made in a hurry. In conclusion, butyl rubber adhesive tape is a versatile and reliable material that offers strong adhesion, weather resistance, and chemical resistance properties. It is commonly used in the construction, automotive, aerospace, and marine industries for sealing, insulation, and bonding applications. With its high tackiness and durability, butyl rubber adhesive tape provides a secure and long-lasting seal that can withstand the harshest of conditions. For DIYers, the user-friendly nature of white PVC insulation tape is a significant advantage. It can be manually torn without the need for tools, thanks to its pre-scored lines that offer clean breaks. This convenience cannot be overstated, as it saves time and effort, allowing quick repairs and adjustments without the frustration of dealing with tough-to-tear materials. The Versatile Role of Insulation Cotton Tape in Modern Applications It is a non-tacky silicone-rubber tape that is used for adhesion or protection of materials. Rubber tapes are used in many areas like providing protection and electrical insulation layer for different equipment like cables and electrical joints. Rubber tape is resistant to heat, weather and sunlight. In solar module manufacturing, it is widely used as a sealant due to its mainly good mechanical properties, impact resistance, high adhesion properties, and relatively cheap cost. It is used during manufacturing, installation and normal operation of PV modules for mounting, adhesion and sealing requirements for modules. Advantages and disadvantages of using rubber tape edge sealant Rubber sealing tape meets the demand of a wide variety of difficult sealing applications. It can be used for oversealing of an existing joint or penetration, normal sealing applications which are typically done with a gasket, or liquid sealant/adhesive. The rubber sealant tape is flexible, durable, and abrasion resistant. It is also conformable which helps create an effective seal over contours, edges rivets, and edges. Rubber tape also has good moisture resistance and as an edge sealant primarily prevents moisture ingress and protects components besides insulation splices and connections in electrical components. The rubber tape is susceptible to cuts and abrasion as it has low tear resistance. This disadvantage is increased because the rubber tape is wrapped while stretched, and stays under internal tension. Yet, these same properties, make tape removal when needed clean and easy.

It can be easily cleaned with soap and water, and does not require any special cleaning agents It can be easily cleaned with soap and water, and does not require any special cleaning agents

It can be easily cleaned with soap and water, and does not require any special cleaning agents It can be easily cleaned with soap and water, and does not require any special cleaning agents In terms of usability, Flex Tape is incredibly user-friendly. Simply cut to the desired size, peel off the backing, and press it onto the surface. The tape's thickness and flexibility allow it to mold around corners and contours, ensuring a complete seal without any air pockets. 4. Align walls, doors, and windows. The appliance industry also benefits greatly from adhesive rubber seal strips

In terms of usability, Flex Tape is incredibly user-friendly. Simply cut to the desired size, peel off the backing, and press it onto the surface. The tape's thickness and flexibility allow it to mold around corners and contours, ensuring a complete seal without any air pockets. 4. Align walls, doors, and windows. The appliance industry also benefits greatly from adhesive rubber seal strips