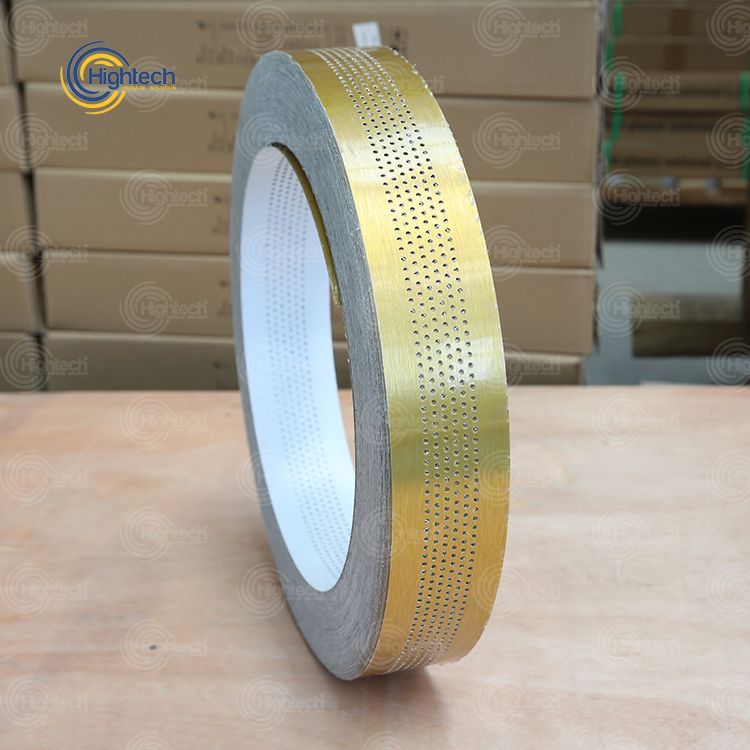

Edge sealing refers to the process of applying a sealant to the edges of materials, particularly those that may be subject to moisture, contaminants, or other environmental factors. The sealant acts as a barrier that prevents the intrusion of water, air, or dirt, thus protecting the integrity of the material. This is essential not only for functionality but also for enhancing the aesthetic appeal of surfaces.

The future outlook for wholesale hand-use aluminum strips appears promising. With the ongoing trends towards lightweight materials across various sectors, the demand is likely to continue growing. Industries such as automotive, construction, electrical, and consumer goods are expected to seek more aluminum solutions, further bolstering the market.

When selecting lighting options, energy efficiency is often a consideration for many consumers. Neon blue LED light strips stand out in this aspect as well. They consume significantly less power compared to traditional incandescent bulbs. This not only helps reduce electricity bills but also aligns with broader environmental goals such as reducing carbon footprints. Additionally, LED strips have a longer lifespan, often lasting up to 50,000 hours. This means fewer replacements and less waste, making them an eco-friendly choice for conscientious consumers.

In today’s competitive marketplace, products are not just evaluated based on their aesthetic appeal but also on their functional attributes and compliance with safety standards. Among various certifications that signify a product’s excellence in quality and performance, CE certification stands out as a pivotal indicator, particularly for products marketed within the European Economic Area (EEA). This article explores the significance of CE certification and delves into the essential attributes of durability, high strength, and flexibility that are critical for sustaining quality in modern manufacturing.

Moreover, standard neon lights often contain toxic gases like xenon or krypton, which can pose health and safety risks. In contrast, neon LED products are free from hazardous substances, making them a safer choice for both indoor and outdoor environments. For businesses, adopting energy-efficient lighting solutions can also lead to substantial savings over time, contributing to a more sustainable operational model.

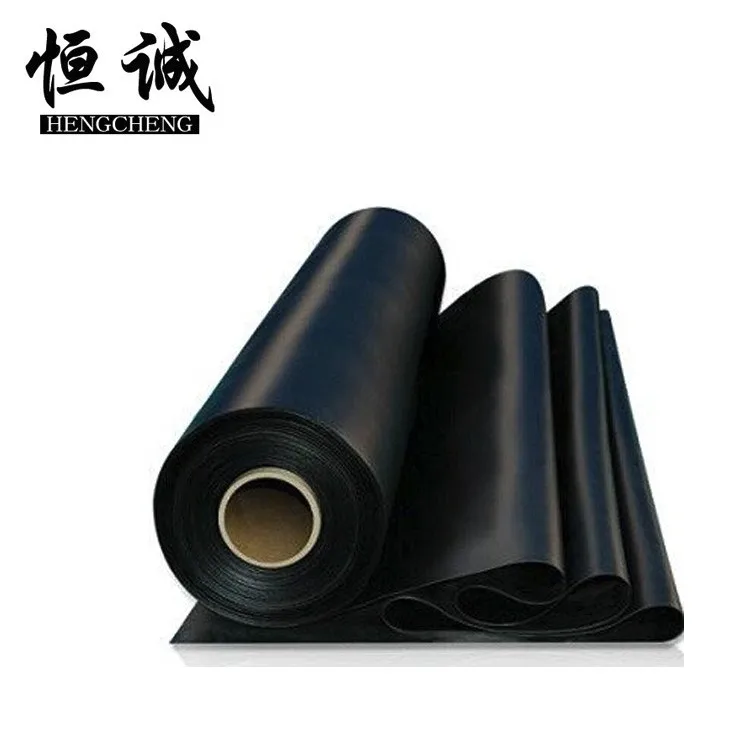

While durability and strength are widely recognized as imperative product attributes, flexibility should not be underestimated. Flexibility allows products to adapt to various conditions without cracking or breaking, making them more versatile and user-friendly. For example, flexible materials are essential in industries like textiles and packaging, where adaptability can significantly enhance usability. Flexible products can accommodate dynamic environments and varying conditions, which is increasingly important in a world prone to rapid changes in design and usage needs. CE certification ensures that these flexible materials meet the required standards of performance under different stress conditions.

Flexi seal strip suppliers are crucial facilitators in the construction ecosystem. They are responsible for sourcing high-quality products from manufacturers and distributing these materials to contractors and builders. A reliable supplier understands the diverse needs of their clients and offers a wide range of options in terms of size, shape, and material composition of seal strips. This variety allows builders to select the appropriate product for specific applications, be it window installations, roofing systems, or exterior cladding.

When it comes to enhancing the comfort and energy efficiency of your home, one often-overlooked component is the door seal strip. Specifically, the custom door bottom seal strip available at Lowe's can make a difference not just in terms of insulation, but in aesthetic appeal as well. In this article, we'll delve into how a door bottom seal can improve your home's environment, the types available at Lowe's, and tips on installation.