Shower door vertical seal strips are vital components in effective bathroom designs, enhancing both function and aesthetics. For construction professionals, understanding the different types available and the benefits of wholesale purchasing can greatly impact the efficiency and quality of their projects. As the demand for advanced bathroom solutions continues to rise, investing in high-quality, reliable shower door vertical seal strips is more important than ever. By choosing wholesale options, contractors can ensure they have the best materials at competitive prices, ultimately leading to satisfied clients and successful projects.

Door seals with rubber strips play a crucial role in energy efficiency and environmental protection in buildings. Exporters are key facilitators in the global supply chain for these products, linking manufacturers to international markets. While the demand for rubber door seals continues to rise, exporters must navigate various challenges to maintain their competitive edge. With a focus on quality, innovation, and sustainability, they can thrive in this dynamic marketplace, contributing to a more energy-efficient and comfortable world.

China has become a significant player in the global silicone sponge seal market thanks to its advanced manufacturing techniques and cost-effective production capabilities. Numerous manufacturers in China offer a diverse range of silicone sponge seal solutions tailored to specific needs. For instance, they can be produced in various shapes, sizes, and densities, allowing for customization that meets the unique requirements of different applications. Whether it is for the construction of HVAC systems, sealing electronic enclosures, or automotive parts, China silicone sponge seals offer a solution that doesn't compromise on quality or performance.

In conclusion, glass rubber seal strip manufacturers play a critical role in the integrity and longevity of glass applications across various industries. By providing high-quality, durable seal strips tailored to specific needs, these manufacturers contribute significantly to enhancing the efficiency and performance of products, ensuring safety and comfort for end-users. Whether in construction, automotive, electronics, or aerospace, the impact of effective sealing solutions cannot be overstated.

Trim strips are designed to be both decorative and protective. They are typically made from materials such as rubber, vinyl, or plastic and can be found on various parts of a car, including door edges, bumpers, and grilles. The choice of red trim strips can add a sporty and dynamic look to the vehicle, appealing to car enthusiasts who want to customize their vehicles. Beyond aesthetics, these trim strips also provide a layer of protection against scratches and other minor damages, helping to maintain the overall appearance and resale value of the vehicle.

Seal strip doors, often referred to as strip curtains or flexible doorways, are made from a series of overlapping plastic or vinyl strips that are designed to create a barrier while allowing for easy passage of people and goods. These doors are reversible and can be installed in various settings, including warehouses, distribution centers, manufacturing facilities, and even residential areas. The main purpose of a seal strip door is to minimize air transfer between spaces, thereby improving insulation and controlling climate.

Wardrobe door seal strips serve multiple purposes, making them an indispensable facet of wardrobe design. Primarily, these strips are designed to prevent dust, moisture, and unwanted pests from entering the wardrobe. This not only keeps your clothing and accessories clean and fresh but also significantly extends their lifespan. Furthermore, seal strips contribute to energy efficiency by helping maintain the temperature of your closet, which is particularly important if your wardrobe is part of a climate-controlled room.

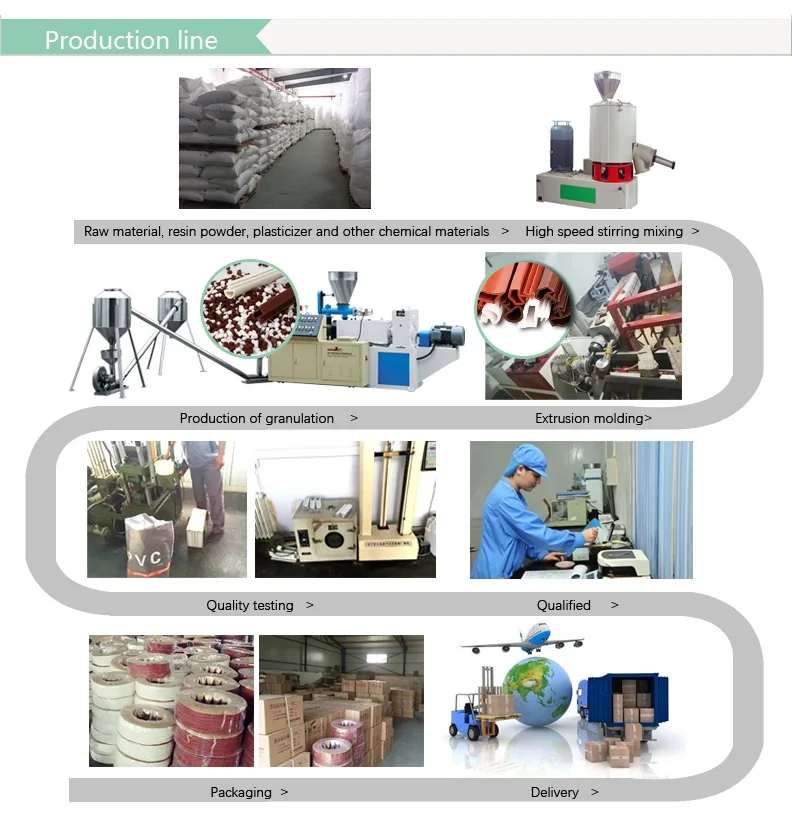

Next, the materials are compounded and formulated to achieve the desired hardness, flexibility, and durability. This stage often includes the addition of fillers, colorants, and other additives. The compounded material is then molded into the desired shape using processes like extrusion or injection molding.