Fiber Reinforced Plastic, or FRP, is a composite material made from a polymer matrix reinforced with fibers, typically glass or carbon. This unique composition gives FRP tanks their exceptional strength-to-weight ratio and makes them highly resistant to a variety of environmental stresses, including corrosive substances, extreme temperatures, and UV radiation. These properties are critical for underground applications where traditional materials like concrete or steel may deteriorate over time, leading to costly repairs or replacements.

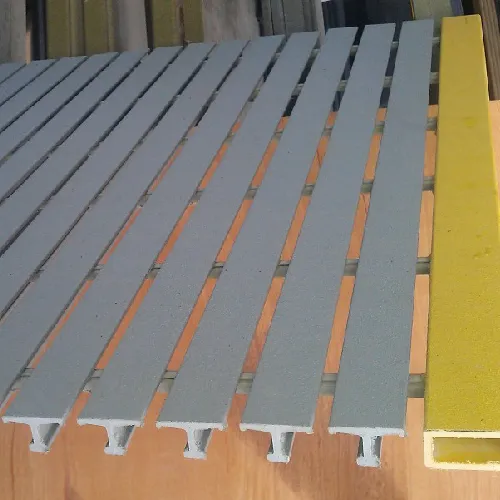

In conclusion, GRP walkway grating represents a significant advancement in industrial flooring solutions. Its combination of strength, safety, and environmental compatibility positions it as a preferred choice across a myriad of applications. As industries continue to prioritize safety, efficiency, and sustainability, the adoption of GRP materials is likely to grow, paving the way for safer and more durable industrial environments. Whether enhancing workplace safety or contributing to environmentally responsible practices, GRP walkway grating is undeniably an essential element in the modern industrial landscape.

The versatility of FRP rods is another significant advantage. They can be molded into various shapes and sizes, allowing for a wide range of applications across different industries. In construction, FRP rods are often used as reinforcement in concrete structures, providing additional tensile strength while reducing weight. In the aerospace and automotive industries, these rods are utilized to improve performance and fuel efficiency without compromising safety. Additionally, FRP rods find applications in telecommunications, where they are used in the construction of lightweight and robust masts and towers.

Despite the many benefits, it is important to note that GRP pultruded grating does have some limitations. For instance, while it is resistant to many chemicals, it may not be suitable for exposure to highly concentrated acids or other specific substances. Additionally, GRP can sometimes have a higher initial cost than traditional materials, which may deter some businesses from making the switch. However, the long-term benefits often outweigh these considerations when factoring in the durability and low maintenance requirements.

One of the most significant advantages of GFRP bars is their high resistance to corrosion. Steel reinforcement is susceptible to rust and degradation, especially when exposed to moisture and chemicals. In contrast, GFRP bars can withstand harsh environments, making them an ideal choice for projects in coastal areas, chemical plants, and regions with high humidity. This resistance not only prolongs the lifespan of the structure but also reduces maintenance costs over time.

As the demand for sustainable building materials continues to grow, walkway FRP stands out as a progressive solution that combines strength, durability, environmental benefits, design flexibility, and safety. With infrastructure being a significant contributor to environmental challenges, adopting materials like FRP can pave the way for a more sustainable future. Whether for urban development or rural pathways, the advantages of walkway FRP make it an intelligent choice for developers and municipalities looking to invest in resilient, eco-friendly infrastructure. The shift towards this innovative material is not just a trend; it reflects a broader commitment to sustainability and responsible construction practices that will benefit generations to come.

While the initial investment in a whole house RO system may seem high, it can be a cost-effective solution in the long run. Bottled water can be expensive, and over time, the costs associated with purchasing bottled water can exceed the cost of a home filtration system. Furthermore, when using purified water throughout the home, there is less need for repairs or replacements of appliances that may be damaged by impurities in the water supply.

Water is an essential resource for life, but not all water is created equal. In many regions, especially those with hard water, the presence of excessive minerals, such as calcium and magnesium, can lead to various issues both in households and industries. Hard water can cause scale buildup in pipes, reduce the effectiveness of soaps and detergents, and even damage appliances. This is where water softener systems come into play, offering a solution to mitigate these problems.

FRP bars, made from materials such as carbon, glass, or aramid fibers, boast several advantages over traditional steel rebar. One of the primary benefits is their resistance to corrosion, making them ideal for use in harsh environments such as marine settings and areas with high salinity or chemical exposure. FRP bars are also lightweight, reducing transportation and labor costs, and they exhibit high tensile strength, which effectively complements the compressive strengths of concrete.