Ultimately, the price of floor marking tape should be weighed against the quality, durability, and longevity of the product

. It is important to do your research and compare prices from different suppliers to find the best value for your specific needs.At its core, insulation tape is designed to insulate electrical wires and other conductive materials. The 50mm width makes it especially suited for larger cables and applications where broader coverage is necessary. Typically made from a blend of PVC and rubber, black insulation tape is favored for its durability and resistance to electric current, heat, and moisture. The black color also provides a sleek look that blends well with many surfaces, making it ideal for both visible and hidden applications.

In most cases, you can choose different colors for your tapes. Depending on the purpose of the tape and the industry you work in, you may need to choose pre-determined colors for specific purposes. Classic examples include red for restricted areas, blue for medical purposes, and yellow and black caution tape for dangerous areas. Tape color coding varies according to individual needs, but there are some global standards.

Moreover, the application process of floor marking tape is user-friendly. It does not require complex tools or expertise, enabling anyone to apply it quickly and efficiently. This convenience factor further enhances its appeal, making it accessible for small businesses or DIY home projects alike.Electrical Applications

One of the key benefits of self-vulcanizing tape is its durability. Once applied, the tape is resistant to water, oil, UV rays, and extreme temperatures, making it ideal for use in a variety of environments. This means that you can trust the tape to hold up under tough conditions and provide a reliable seal that won't let you down. Moreover, coloured electrical tape provides an added layer of protection against damage and corrosion

coloured electrical tape. When wrapped around wires and cables, it creates a barrier that prevents moisture, dirt, and other contaminants from penetrating and causing harm. This is particularly useful in areas where the wires are likely to be subjected to physical wear and tear, such as in industrial settings or on construction sites.

coloured electrical tape. When wrapped around wires and cables, it creates a barrier that prevents moisture, dirt, and other contaminants from penetrating and causing harm. This is particularly useful in areas where the wires are likely to be subjected to physical wear and tear, such as in industrial settings or on construction sites. The Importance of Fire-Resistant Electrical Tape

Conclusion: The Central Hub of Your Electrical System

For industries engaged in hazardous material handling, Zebra marking tape is essential due to its chemical resistance properties. It maintains the integrity of the label even when exposed to corrosive substances, thereby safeguarding workers and complying with regulatory standards. The process of applying floor marking begins with surface preparation—ensuring the area is clean, dry, and free from debris. Then, using stencils, tape, or pre-cut vinyl shapes, the design is laid out meticulously before application Then, using stencils, tape, or pre-cut vinyl shapes, the design is laid out meticulously before application Then, using stencils, tape, or pre-cut vinyl shapes, the design is laid out meticulously before application Then, using stencils, tape, or pre-cut vinyl shapes, the design is laid out meticulously before application

Then, using stencils, tape, or pre-cut vinyl shapes, the design is laid out meticulously before application Then, using stencils, tape, or pre-cut vinyl shapes, the design is laid out meticulously before application floor marking. The chosen material is then applied carefully to avoid bubbles, overlaps, or smudges. Once set, the marking should be protected with a topcoat if necessary and inspected regularly for wear and tear. The importance of insulating strips becomes evident when considering scenarios without them. Exposed wires pose a significant risk of electrocution, while improperly insulated pipes can cause condensation and energy loss. Furthermore, without the acoustic insulation provided by these strips, noise pollution would increase, affecting comfort and productivity in homes and offices alike. Price is another important factor to consider when choosing a butyl rubber tape supplier

floor marking. The chosen material is then applied carefully to avoid bubbles, overlaps, or smudges. Once set, the marking should be protected with a topcoat if necessary and inspected regularly for wear and tear. The importance of insulating strips becomes evident when considering scenarios without them. Exposed wires pose a significant risk of electrocution, while improperly insulated pipes can cause condensation and energy loss. Furthermore, without the acoustic insulation provided by these strips, noise pollution would increase, affecting comfort and productivity in homes and offices alike. Price is another important factor to consider when choosing a butyl rubber tape supplier The production process of PVC electrical tape involves a combination of science and art. Raw materials, primarily PVC resin, plasticizers, stabilizers, and adhesives, are compounded and then processed through extrusion and coating techniques. The tape is then wound onto rolls and undergoes quality control checks to ensure compliance with international standards such as UL, CSA, and RoHS.

The production process of PVC electrical tape involves a combination of science and art. Raw materials, primarily PVC resin, plasticizers, stabilizers, and adhesives, are compounded and then processed through extrusion and coating techniques. The tape is then wound onto rolls and undergoes quality control checks to ensure compliance with international standards such as UL, CSA, and RoHS. 2. Stretch the tape Most amalgamating tapes come on a roll and need to be stretched before application. Gently stretch the tape to activate the adhesive properties.

In construction projects, floor line tape plays a crucial role in ensuring the accuracy and precision of work. It helps workers Another key feature of flexible transparent tape is its durability. It can withstand extreme temperatures, humidity, and even exposure to sunlight without losing its adhesive properties. This makes it an excellent choice for outdoor projects or environments where the tape will be subjected to harsh conditions.

Tape wraps are a popular choice for temporary repairs or quick fixes, as they are easy to apply and remove. However, they are not as durable or long-lasting as plastic or fabric wraps, and may need to be replaced more frequently.

When evaluating PVC insulation tape manufacturers, potential buyers should consider several factors. Firstly, the reputation of the manufacturer is paramount. Look into their history, client testimonials, and any industry accolades they may have received. A manufacturer with a proven track record of delivering high-quality products is more likely to meet your needs.

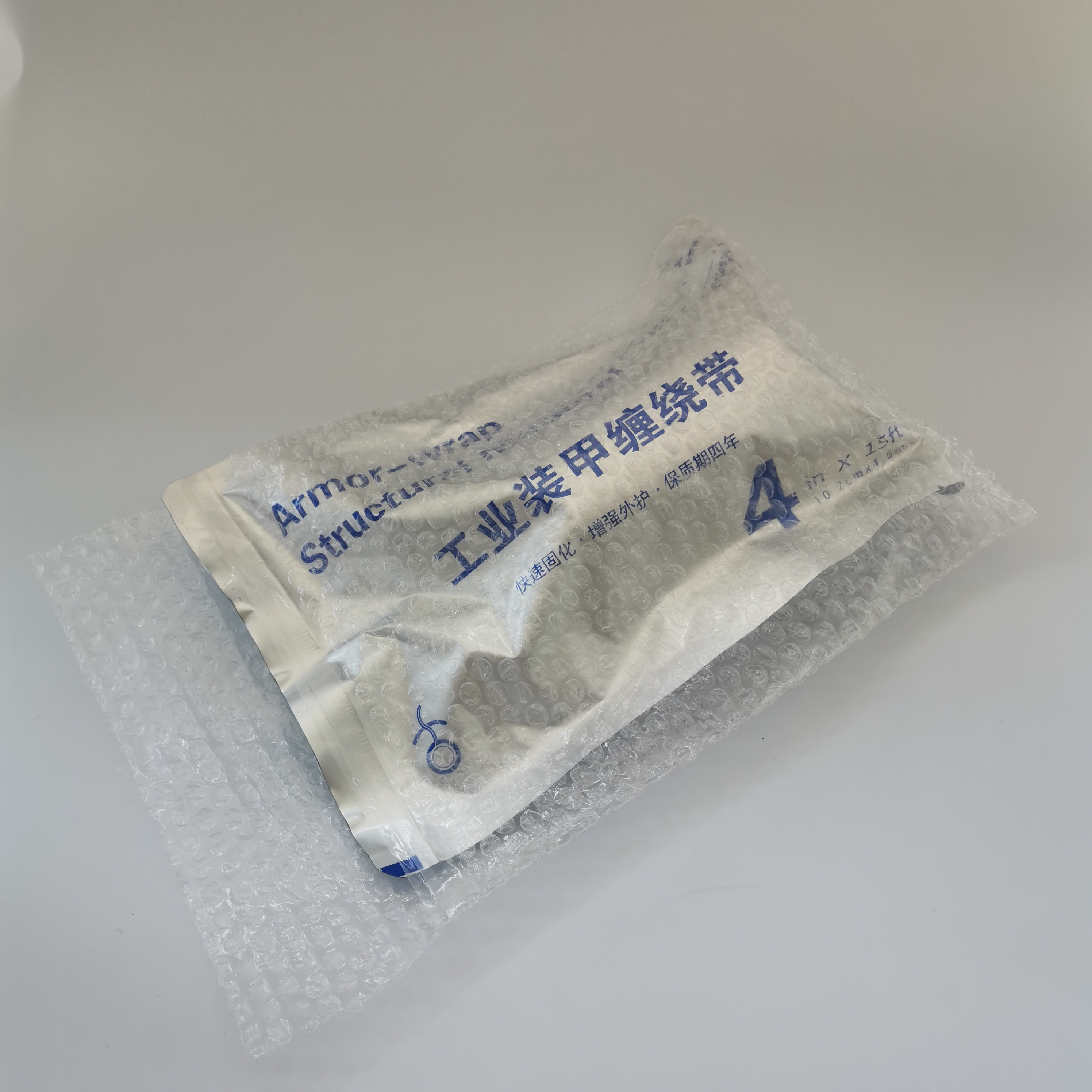

XF-KJD The special glass fiber is woven into the high-strength and high-elastic fabric with self-developed technology a glass fiber product made of water-cured polymer. lt has the advantages of fast curing in water, easy operation, and a wide range of applications and other characteristics, the structure formed after curing bending strength and tensile strength is high, non-toxic tasteless without stimulation, water resistance, and corrosion resistance.

4. Neoprene Rubber Tape: Neoprene rubber tape is a versatile material that is suitable for a wide range of applications. It is known for its resistance to heat, oil, and chemicals, which makes it ideal for automotive and industrial applications.

Width: Available in 19mm and 25mm

Moreover, brown insulation tape is not only limited to electrical applications