ABS is a copolymer made from three monomers acrylonitrile, butadiene, and styrene. This unique combination endows ABS with excellent properties, including good impact resistance, toughness, and the ability to withstand high temperatures. These characteristics make ABS an ideal choice for 3D printing applications, allowing for the creation of intricate designs with fine details. Its vibrant colors and ease of post-processing contribute to its popularity among both hobbyists and professionals in the 3D printing community.

LED split neon lights offer significant advantages over traditional lighting alternatives. One of the most notable benefits is their energy efficiency. LED technology consumes considerably less power than incandescent or fluorescent bulbs, leading to reduced energy bills and lower environmental impact. Furthermore, the long lifespan of LED lights, often exceeding 25,000 hours, means reduced replacement costs and less waste.

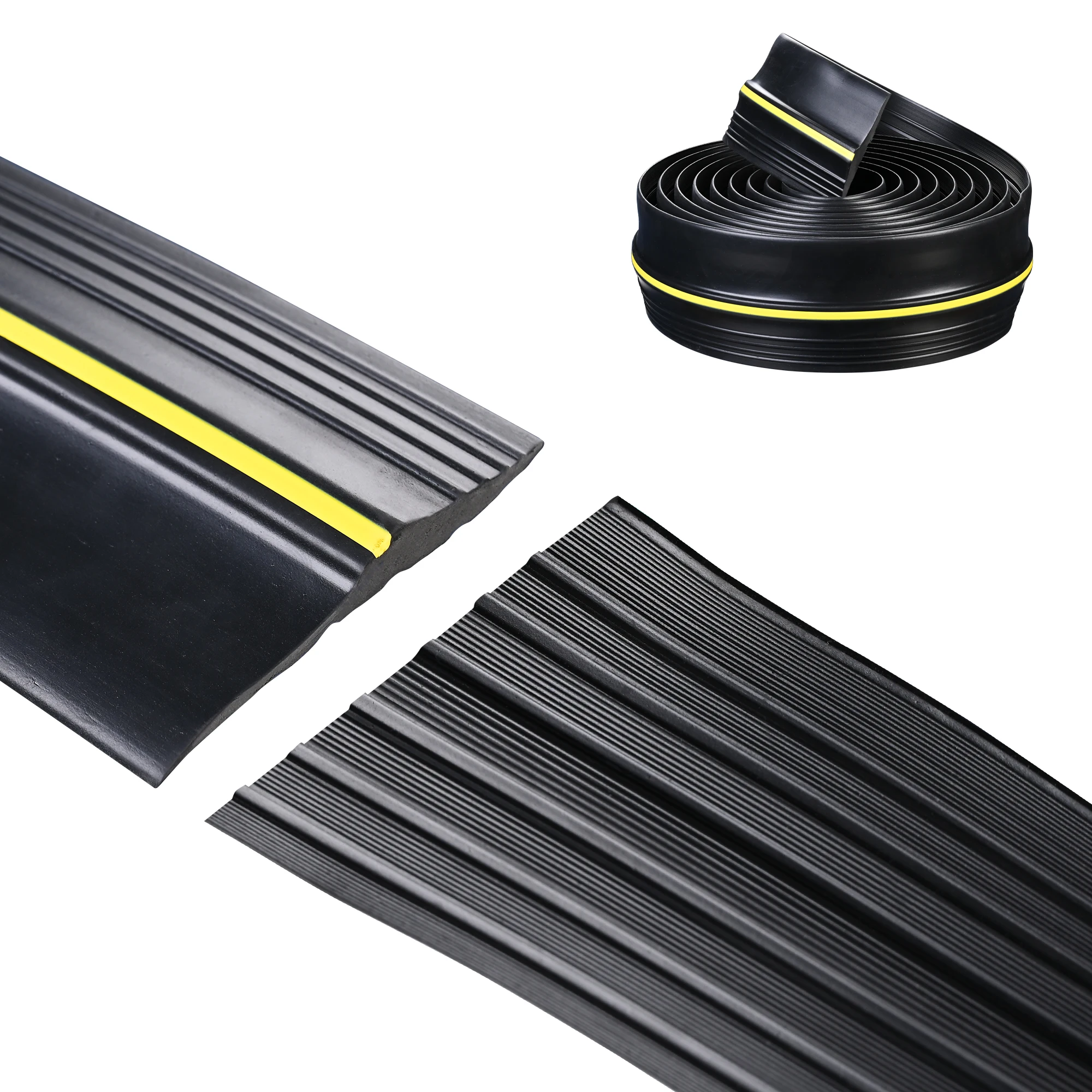

The front door bottom seal strip may seem like a minor detail in the grand scheme of home maintenance, but its role in ensuring comfort, energy efficiency, moisture control, and pest prevention cannot be overstated. Regular inspections and timely replacements or repairs of this component are essential for maintaining a safe and comfortable home environment. Whether you choose to tackle this maintenance task yourself or hire a professional, ensuring the integrity of your front door seal strip should be a priority for every homeowner. Taking proactive measures now can lead to a more comfortable, efficient, and durable living space for years to come.

The ultimate goal of CE certification is to ensure that products are safe, reliable, and perform under expected conditions. Products that exhibit durability, high strength, and flexibility align perfectly with this aim. These attributes work together to provide a robust product that not only satisfies consumer expectations but also complies with regulatory standards. For manufacturers, understanding the synergy between these qualities can lead to innovative designs that push the boundaries of what products can achieve.

When selecting trim materials, designers must consider several factors, including functionality, cost, aesthetics, and sustainability. The trim should not only enhance the product’s appearance but also serve its intended purpose without compromising durability. Moreover, with the growing emphasis on sustainability, choosing eco-friendly materials can also be a significant selling point for modern consumers.

In conclusion, black PVC price strip products are integral to various industries, providing essential benefits such as insulation, sanitation, and efficiency. Understanding the factors that influence their pricing can aid businesses in making informed purchasing decisions. As the market continues to adapt to changing demands and sustainability practices, stakeholders must keep a pulse on trends and innovations that could shape the pricing dynamics in the coming years. Recognizing the balance between quality and cost is key to leveraging these products effectively in any commercial environment.

The Elan 2S chrome rocker trim strip is designed for a perfect fit along the rocker panels of many vehicles. The rocker panels are the sections of the car located below the doors, and they often face exposure to road debris, dirt, and other elements that can cause damage over time. By installing chrome rocker trim strips, not only do you enhance your vehicle’s aesthetic appeal, but you also provide an additional layer of protection.

In conclusion, P Seal Strip Company stands out in the seal strip industry for its unwavering commitment to quality, customer satisfaction, and innovation. By focusing on specific customer needs, using high-quality materials, and embracing sustainability, the company has carved a niche for itself as a trusted supplier of sealing solutions. As industries continue to evolve and demand more efficient and durable products, P Seal Strip Company is well-positioned to meet these challenges head-on, ensuring that their clients receive only the best in seal strip technology. Whether you are in the automotive, construction, or HVAC sector, partnering with P Seal Strip Company can provide the reliability and performance needed to thrive in today’s competitive environment.

Door seal strips are materials designed to close the gaps around doors, preventing air leaks, water intrusion, and pest entry. They are typically made from a variety of materials, including rubber, foam, and vinyl. The primary function of these strips is to create a tight seal when a door is closed, which is crucial for maintaining consistent temperatures inside the home, reducing energy costs, and enhancing overall comfort.

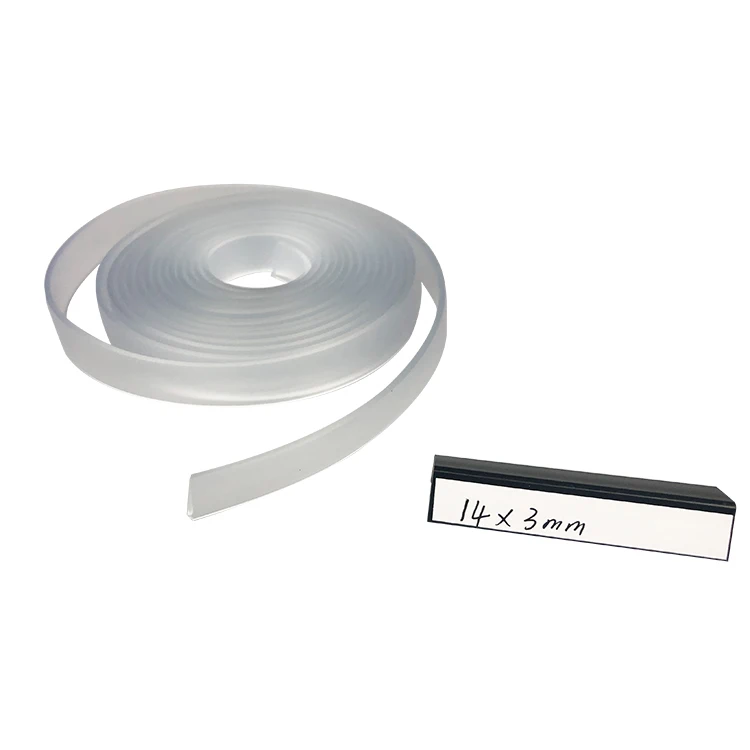

Vertical seal strips are designed to create a watertight barrier along the vertical edges of shower doors. They are typically made from materials such as vinyl, rubber, or silicone, which have excellent water-resistant properties. These strips are essential for preventing leaks from the shower enclosure. When properly installed, they can keep water contained within the shower area, ensuring that the bathroom remains dry and safe.