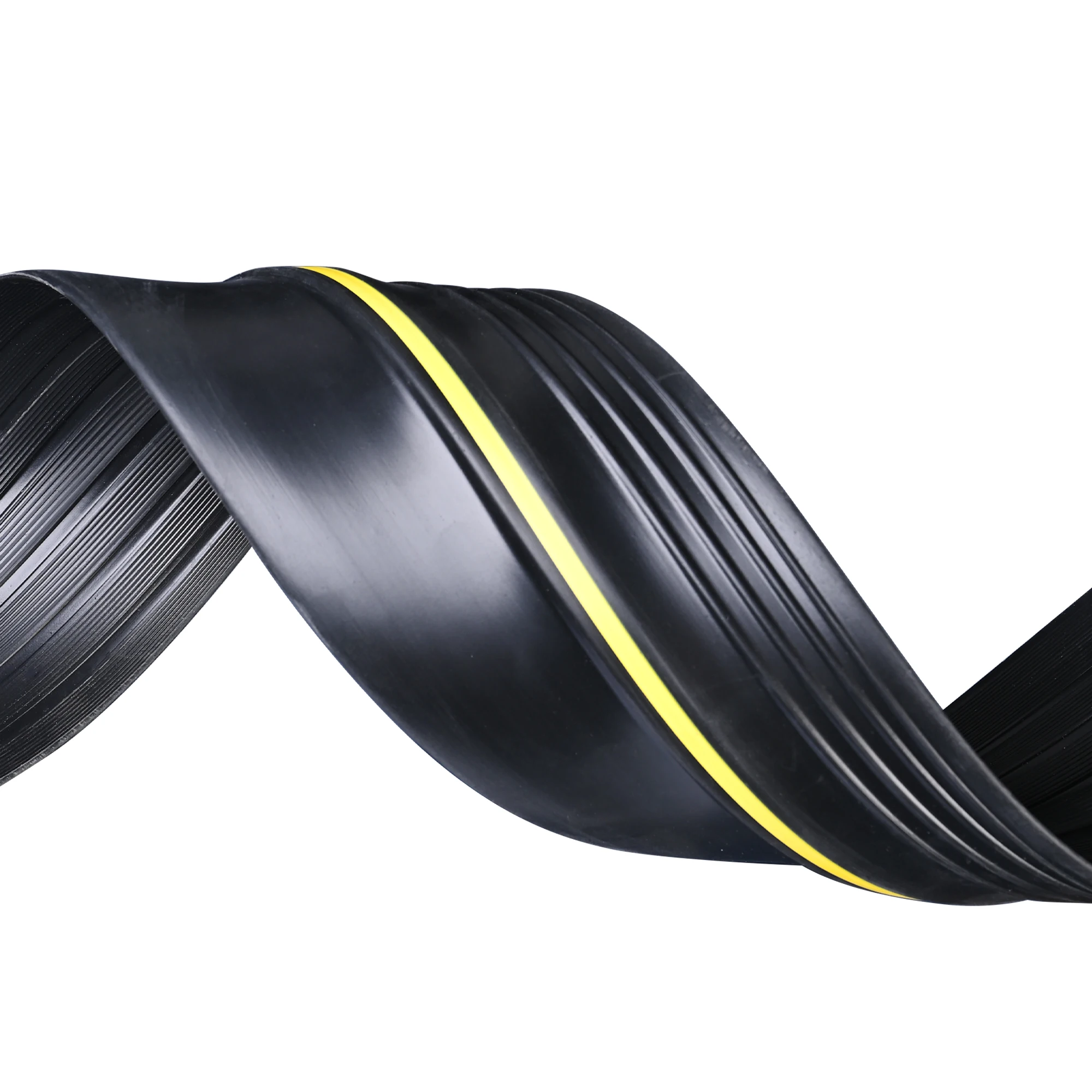

Rubber floor seal strips are specialized strips made of durable rubber material designed to create a secure seal between different flooring surfaces or between the floor and walls. They are typically used in commercial and industrial settings, including warehouses, factories, hospitals, and laboratories, where cleanliness and safety are critical.

In conclusion, the kitchen worktop seal strip may seem like a minor component in the grand scheme of kitchen design, but its importance cannot be understated. CE certification plays a pivotal role in ensuring that these products meet essential safety and quality standards. By favoring CE-certified kitchen worktop seal strips, consumers can enjoy a functional, aesthetically pleasing, and hygienic kitchen environment, while manufacturers can demonstrate their commitment to quality and regulatory compliance.

Weather door seal strips are designed to fill the gaps around doors and windows to prevent drafts, moisture, and pests from entering a building. They are typically made from durable materials such as foam, rubber, or vinyl and are available in various sizes and styles to suit different door configurations. The primary purpose of these seals is to create a tight barrier that helps maintain the inside temperature, be it warm or cool, and prevents the loss of conditioned air.

When it comes to maintaining the integrity and comfort of a vehicle, one often overlooked aspect is the quality of the auto door seal strips. These components may seem minor, but they play a critical role in ensuring that vehicles are both functional and comfortable. A well-designed seal strip prevents water, dirt, and noise from entering the vehicle, thereby enhancing the overall driving experience. In this article, we will explore the significance of auto door seal strips and highlight some of the leading companies in this niche industry.

In practical applications, J-type fonts and designs are often used in signage, branding, and digital media, where they convey clarity and elegance. The shapes are versatile, allowing for easy readability and an appealing visual flow. Furthermore, the integration of the J-type design within a 2cm constraint means that designers can create compact yet impactful graphics. Whether in advertising banners, mobile interfaces, or product packaging, J-type designs thrive in spaces where succinctness and attractiveness are imperative.

OEM car molding trim strips are designed to be fitted seamlessly along various parts of a vehicle’s body, including door edges, bumpers, and windows. These strips serve multiple purposes, primarily protecting the vehicle from external elements while also providing a finished look to the car. By using high-quality materials specifically engineered for durability, OEM trim strips help mitigate the effects of weathering, such as UV radiation and moisture, which can lead to degradation over time.

In conclusion, ABS aluminum suppliers are essential players in providing the materials necessary for the advancement of multiple industries. By delivering high-quality products, offering customization, and supporting sustainable practices, these suppliers help businesses innovate and thrive in a competitive landscape. As technology continues to progress, the role of aluminum in manufacturing will only grow, and ABS aluminum suppliers will remain at the forefront of this evolution, ensuring that industries have access to the materials they need to succeed. Whether you are a manufacturer or a project manager, partnering with a reliable ABS aluminum supplier can make a significant difference in your operations, ultimately leading to enhanced product performance and customer satisfaction.