Hydroxypropyl Methyl Cellulose (HPMC) is a cellulose ether widely used in various industries due to its unique properties and versatility. In the context of China, the production and application of HPMC have seen significant growth, driven by the expanding demands in construction, pharmaceuticals, food, and personal care sectors.

. Its biocompatibility and non-toxic nature make it a safe and effective option for incorporating into medicinal products. When you buy hydroxyethyl cellulose for pharmaceutical applications, you can be confident that you are using a reliable and compliant ingredient that meets strict quality standards.

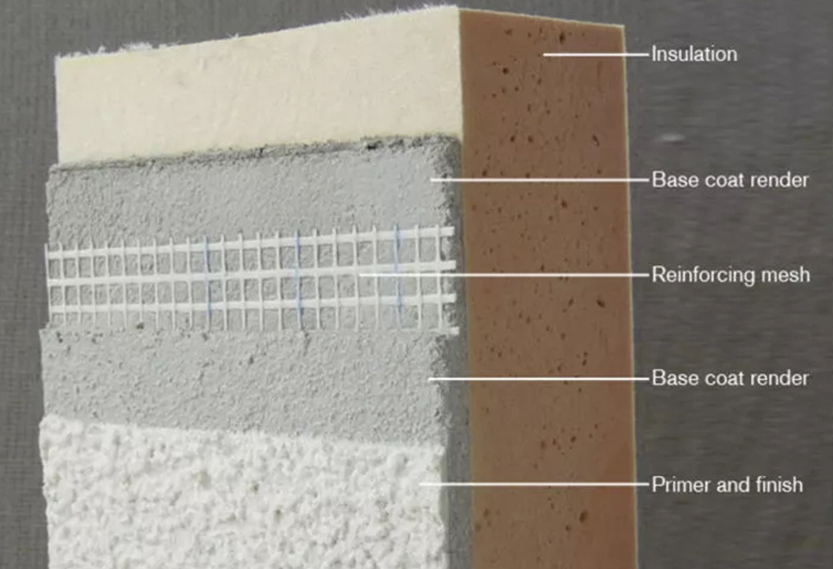

One of the primary applications of RDP powder is in the construction sector, particularly in dry-mixed mortars. When mixed with water, RDP powder provides enhanced adhesion, elasticity, and flexibility to the mortar. This leads to improved durability and performance of the final product. For instance, RDP is widely used in tile adhesives to enhance their bonding strength to substrates such as concrete, ceramic, and wood. The polymer’s ability to maintain consistent performance under varying environmental conditions makes it a staple in both indoor and outdoor applications.

Hydroxypropyl methylcellulose is a versatile, non-ionic cellulose ether derived from natural cellulose. It is widely recognized for its unique properties, including thickening, binding, emulsifying, and film-forming capabilities. These properties make HPMC an essential ingredient in a plethora of products, ranging from paints and coatings to adhesives and dietary supplements. HPMC Company specializes in the manufacturing and distribution of HPMC products tailored to meet the specific needs of various industries.

The Food and Drug Administration (FDA) includes Ethylcellulose, Hydroxypropylcellulose, Methyl Ethylcellulose and Hydroxypropyl Methylcellulose on its list of multipurpose additives allowed to be directly added to food. FDA also permits Cellulose and a number of modified cellulose polymers to be used as indirect food additives. For example, Cellulose, Cellulose Acetate Butryate, Cellulose Acetate Propionate, Cellulose Gum, Hydroxyethylcellulose, Hydroxyethyl Ethylcellulose, Hydroxypropyl Methylcellulose and Methylcellulose can be used in adhesives in contact with food. As substances migrating to food from paper and paperboard products, FDA considers Cellulose Acetate and Ethylcellulose to be Generally Recognized as Safe (GRAS). The FDA has also approved the use of Cellulose Gum, Hydroxyethylcellulose, Hydroxypropyl Methylcellulose and Methylcellulose for use as ophthalmic demulcents in over-the-counter (OTC) drug products for the eyes.

The food industry also benefits from the unique properties of HPMC. It serves as a thickening and stabilizing agent in various food products, such as sauces, dressings, and ice creams. By improving texture and mouthfeel, HPMC enhances the overall sensory experience of food products. Moreover, its emulsifying properties help to maintain the stability of emulsions, preventing separation of ingredients. This makes HPMC an essential ingredient in many processed foods, where it contributes to the consistency and quality expected by consumers.

One of the primary advantages of hydroxyethylcellulose is its ability to effectively thicken solutions without altering their pH levels. This attribute makes HEC an excellent additive in cosmetics and skincare formulations. Products such as lotions, creams, and gels rely on thickening agents to achieve the desired viscosity, which enhances the sensory experience during application. Moreover, HEC helps to create a smooth texture, ensuring that the product glides easily on the skin.