The rubber products made by molding process are mainly structural connectors, protective seals and electrical insulation parts, which are made into sealing rings, gaskets, protective sleeves, sealing plugs, edging sleeves, gaskets, oil seals, miscellaneous parts and other products.

External door rubber seals, also known as weatherstripping, are flexible strips made from materials like rubber, foam, or vinyl, designed to fit around the edges of doors. Their primary function is to fill in the gaps between the door frame and the door itself, creating a barrier against the elements. This prevents drafts, moisture, and dirt from entering your home while also contributing to noise reduction and enhanced security.

From a sustainability standpoint, using adhesive door seals aligns with environmentally friendly practices. By improving energy efficiency, they contribute to lower energy consumption and, by extension, a reduced carbon footprint. In an era where environmental consciousness is becoming increasingly important, every step taken towards efficiency counts.

Door weather stripping is a material used to seal the gaps around doors, preventing air leaks, moisture intrusion, and dust while enhancing energy efficiency. The bottom of the door is particularly vulnerable to outside elements, as it's the point where the door meets the floor. Weather stripping at this location helps to create a barrier against cold drafts in winter, hot air in summer, and even pests that might enter your home.

In conclusion, edge strips are indispensable elements in material design that offer both practical and aesthetic benefits. Their ability to protect, enhance durability, and elevate the visual appeal of products makes them a valuable consideration for designers across various industries. As design trends continue to evolve, the significance of edge strips will undoubtedly grow, paving the way for innovations that prioritize both functionality and sustainability. Embracing the potential of edge strips will not only improve product quality but also contribute to the creation of visually stunning and enduring designs that meet the demands of modern consumers.

Car rubber edge trim is a flexible, often adhesive-backed strip made from durable rubber or plastic materials. It is designed to be applied to the edges of doors, hoods, trunks, and other body parts. This trim serves multiple purposes, primarily to protect the vehicle's body from scratches, dents, and other potential damage caused by bumps and knocks during daily use.

In summary, wide rubber weather stripping is an essential component for any homeowner looking to enhance comfort, improve energy efficiency, and reduce noise in their living spaces. With its ease of installation and durability, it is a practical solution that pays off in the long run. By taking the time to assess your home’s needs and applying this effective sealing material, you can create a more enjoyable living environment and contribute to energy conservation efforts. Whether you live in a drafty old house or a modern apartment, incorporating wide rubber weather stripping into your home improvement projects is a smart investment.

When it comes to ensuring your home is energy-efficient, secure, and comfortable, one often overlooked aspect is the bottom of your doors. Door bottoms, also known as door sweeps, play a crucial role in preventing drafts, pests, and moisture from entering your living spaces. They can also enhance the aesthetic appeal of your home. In this article, we will explore the various types of door bottoms, their features, and their benefits to help you make an informed choice.

In conclusion, black foam tape, particularly in its single-sided form, is a versatile and practical solution for a multitude of applications. Its unique combination of cushioning, insulation, and adherence makes it an essential tool for various industries and home projects alike. Whether sealing out drafts, mounting electronic components, or simply engaging in creative DIY endeavors, black foam tape proves to be a reliable ally in achieving high-quality results. Embracing this humble tape can significantly enhance both efficiency and effectiveness in your projects, making it an indispensable addition to your toolkit.

Booster pump mechanical seals are fundamental to the efficient and reliable operation of pumping systems. Understanding their design, functionality, different types, and the importance of maintenance can significantly enhance operational performance and prevent costly downtime. By investing in quality seals and adhering to rigorous maintenance protocols, industries can ensure that their booster pumps operate at peak efficiency, delivering reliable service for years to come.

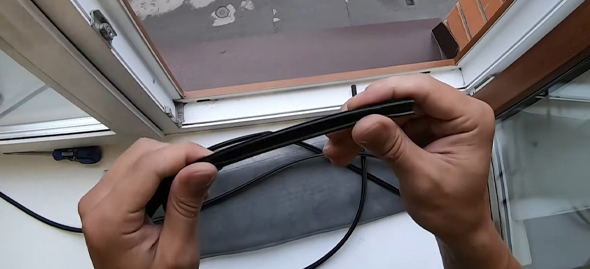

Be careful not to damage the glass or the door frame during this process Be careful not to damage the glass or the door frame during this process

Be careful not to damage the glass or the door frame during this process Be careful not to damage the glass or the door frame during this process

It's essential to choose weather stripping that is durable and can withstand the fluctuations in temperature and humidity It's essential to choose weather stripping that is durable and can withstand the fluctuations in temperature and humidity

It's essential to choose weather stripping that is durable and can withstand the fluctuations in temperature and humidity It's essential to choose weather stripping that is durable and can withstand the fluctuations in temperature and humidity