Features of self-amalgamating tape

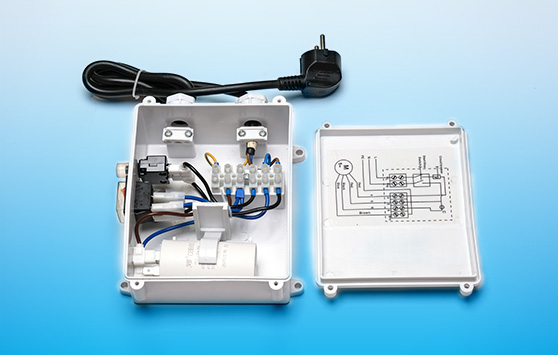

The manufacturing process of PVC electrical insulation involves several steps. First, PVC resin is mixed with plasticizers, stabilizers, and other additives to create a homogeneous mixture. The mixture is then fed into an extruder, where it is heated and forced through a die to create a thin tube or sheet. The extruded material is then cooled and cut into the desired shape and size. Finally, the insulation is inspected for quality and packaged for distribution.The power supply unit links your control box to your main supply or power source. It also ensures that the power comes within the ideal current and voltage ranges thereby protecting your linked devices.

It can be easily wrapped around electrical components, joints, and connections to provide a secure and reliable insulation barrier It can be easily wrapped around electrical components, joints, and connections to provide a secure and reliable insulation barrier

It can be easily wrapped around electrical components, joints, and connections to provide a secure and reliable insulation barrier It can be easily wrapped around electrical components, joints, and connections to provide a secure and reliable insulation barrier