Quality assurance is crucial in the production of window bottom seal strips. Inferior products can lead to significant problems, such as leaks, drafts, and increased energy costs – issues that homeowners would want to avoid. Therefore, reputable factories invest in high-quality raw materials and rigorous testing protocols. Collaboration with architectural engineers and builders also helps them understand market needs, leading to the development of innovative products that address real-world challenges.

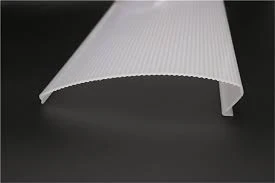

Door seal strips, also known as weatherstripping, are materials applied around doors to prevent drafts, moisture, and insects from entering your home. When installed correctly, these strips can significantly reduce energy loss, ultimately resulting in lower utility bills. They come in various materials, including foam, rubber, vinyl, and metal, each offering different levels of durability and insulation.

Good suppliers will offer a wide range of products, catering to different door and window types, as well as varying insulation needs. They should also provide options that differ in material, thickness, and design, allowing consumers to choose the best fit for their specific requirements. Suppliers that understand market demands and trends also tend to stay ahead, moving towards more sustainable materials and practices, which appeal to environmentally conscious consumers.

In today's fast-paced world, energy efficiency, comfort, and security have become paramount for homeowners and businesses alike. One often-overlooked item that significantly contributes to these aspects is the brush door seal strip. These seals offer an array of benefits, from insulation to noise reduction, making them an essential component in doors.

To harness the benefits of TPE light boxes, businesses must source their materials and components from trustworthy suppliers. High-quality fabrics not only enhance the appearance of the light box but also influence its durability and functionality. When searching for TPE light box fabric suppliers, it is essential to evaluate several factors, including material quality, pricing, customization options, and customer service.

Seal-a-Meal heat strip products represent an intelligent solution to modern food storage challenges. By allowing you to vacuum-seal your food efficiently, they help extend shelf life, reduce waste, and save money. Whether you are a gourmet cook, a meal prep enthusiast, or a busy parent, incorporating Seal-a-Meal vacuum sealers into your kitchen can simplify your food storage process and enhance your culinary experience. With the right products in hand, you can savor the flavors of fresh ingredients for longer while supporting a more sustainable lifestyle.

As the global market for LED neon light stands continues to expand, several challenges may arise. Competition among exporters is fierce, with many companies entering the market to capitalize on its growth potential. Additionally, fluctuations in raw material prices and supply chain disruptions can impact production costs and timelines. Therefore, exporters must be agile and innovative, constantly seeking ways to differentiate their offerings and maintain profitability.

The Custom Seal It insulation strip is a specially designed product that serves as a barrier against heat loss, drafts, and moisture. Made from high-quality materials, these insulation strips can be tailored to fit any door or window size, ensuring a precise fit that maximizes energy efficiency. The customizability of these insulation strips is what sets them apart from standard insulation products, as they can cater to the specific needs of your home or office.