In summary, sectional steel tanks represent a highly efficient and flexible solution for numerous liquid storage needs. With their customizable design, ease of transport and installation, durability, cost-effectiveness, and wide-ranging applications, they have earned their place in various industries. As businesses continue to seek reliable and sustainable storage solutions, sectional steel tanks will undoubtedly remain a favorable choice, aligning operational efficiency with environmental considerations for years to come.

The design of the Pentair Vessel is robust, allowing it to withstand different pressures and environmental conditions, making it suitable for a wide range of applications. The 1465 model, in particular, offers a significant volume capacity, which translates to effective filtration for larger households or commercial enterprises.

3. Tertiary Treatment This advanced treatment stage focuses on removing remaining contaminants, including nutrients such as nitrogen and phosphorus, pathogens, and other pollutants. Various methods, including filtration, chemical treatment, and disinfection (using chlorination or UV light), are employed to ensure that the water meets regulatory standards for discharge or reuse.

In conclusion, GRP insulated water tanks offer a range of benefits that make them an attractive option for water storage solutions. Their superior insulation, corrosion resistance, lightweight nature, cost-effectiveness, and positive environmental impact are just a few reasons they are becoming increasingly popular in both commercial and residential settings. As we continue to prioritize efficient and sustainable water management practices, GRP insulated water tanks are poised to play a significant role in meeting our water storage needs in the future.

In today's rapidly evolving industrial landscape, the demand for efficient and durable storage solutions has never been higher. Among the various materials available for constructing storage vessels, fiberglass reinforced plastic (FRP) has gained immense popularity due to its superior properties. A noteworthy option within this category is the 24% 72 FRP vessel, which offers a unique blend of strength, corrosion resistance, and versatility ideal for various applications.

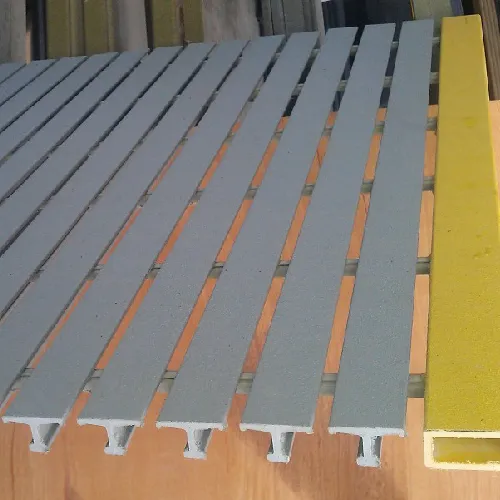

The applications for anti-skid grating are vast and varied. In the industrial sector, it is frequently used in manufacturing plants, assembly lines, and loading docks where heavy machinery operates. These environments often pose a risk of accidents due to spills, debris, or oil leaks. Anti-skid grating not only helps prevent injuries but can also improve efficiency by allowing workers to move safely and confidently.

The increasing adoption of FRP walkways across various sectors, including construction, oil and gas, power generation, and pharmaceuticals, underscores their value in modern industrial applications. As industries continue to prioritize worker safety and operational efficiency, the role of FRP walkway manufacturers will undoubtedly grow.

In conclusion, FRP bridge deck panels represent a significant evolution in bridge engineering. Their lightweight nature, corrosion resistance, design flexibility, and potential for sustainability make them an attractive choice for modern infrastructure projects. As technology and manufacturing processes improve and awareness of the benefits grows, FRP is poised to become a staple material in the future of bridge construction, leading to safer, longer-lasting, and more efficient infrastructure.

In conclusion, sectional cold water storage tanks represent a modern solution to the age-old challenge of water storage. Their modularity, cost-effectiveness, and durability make them suitable for a wide range of applications. As industries and communities continue to seek sustainable and efficient water management systems, sectional tanks are well-positioned to meet these evolving needs, making them a wise investment for the future.

The adoption of FRP softener vessels in water treatment facilities is revolutionizing the way we manage and utilize water resources. Their corrosion resistance, lightweight nature, strength, and thermal properties make them an excellent choice for both industrial and residential applications. As the demand for clean water continues to grow, investing in innovative technologies like FRP softener vessels will be crucial in ensuring sustainable water management practices. With their proven benefits, FRP softener vessels signify a promising step towards improved water quality and efficient water treatment processes globally.