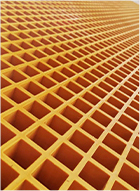

Moulded grating also demonstrates environmental resilience. Its resistance to UV radiation, temperature fluctuations, and environmental pollutants makes it ideal for outdoor applications as well. Unlike wood, it does not warp, crack, or splinter, ensuring a long lifespan with minimal maintenance. This durability translates to lower lifecycle costs, as less frequent replacements are needed compared to traditional materials.

Fiberglass fence rods have an extensive array of applications. In residential settings, they can be used for privacy fencing, garden boundaries, or decorative purposes. Commercially, they are often employed in agricultural fencing, where their durability is crucial for protecting livestock and crops.

In conclusion, galvanized water storage tanks represent a reliable and efficient solution for water storage needs across different sectors. Their inherent properties of corrosion resistance, durability, and low maintenance make them a preferred choice for many users. As the global demand for clean water continues to rise, the role of such storage solutions will likely expand, contributing to better water management practices. Investing in a galvanized water storage tank is not only a practical choice but also a commitment to sustainability and responsible resource management.

In summary, FRP rebar represents a significant advancement in construction materials, offering numerous advantages over traditional steel rebar. Its resistance to corrosion, lightweight nature, and sustainability align perfectly with the growing demand for durable and eco-friendly building solutions. As the construction industry continues to evolve, the adoption of innovative materials like FRP rebar will play a crucial role in shaping the future of infrastructure development. Embracing these materials can lead to safer, more efficient, and longer-lasting constructions, ultimately enhancing the resilience of our built environment.

Constructed from high-quality steel, sectional steel tanks are built to withstand harsh environmental conditions, including extreme temperatures, UV exposure, and severe weather. They are often designed with corrosion-resistant coatings and protective measures, ensuring longevity and reduced maintenance costs. When properly maintained, these tanks can last for several decades, making them a reliable investment for businesses.

FRP trench drains are drainage systems designed to collect and transport surface water away from roads, parking lots, and other impermeable surfaces. Made from a composite of fiberglass and resin, FRP trench drains are known for their durability, lightweight nature, and resistance to corrosion. This makes them particularly well-suited for environments where traditional materials, such as concrete or metal, may fail due to exposure to harsh conditions or chemicals.

Furthermore, FRP trench drains require minimal maintenance and are easy to clean, making them a cost-effective solution for long-term drainage needs. Unlike traditional concrete or metal drains, fiberglass reinforced plastic drains do not rust, corrode, or degrade over time, reducing the need for constant repairs or replacements.

Sectional steel water tanks have gained significant popularity in various applications, particularly for their exceptional durability, modular design, and cost-effectiveness. These tanks are increasingly being used in industrial, commercial, and residential settings for water storage, and their benefits are important to understand.

One of the most defining characteristics of moulded grating is its exceptional strength-to-weight ratio. The incorporation of fiberglass contributes to its lightweight nature while maintaining impressive load-bearing capabilities. This property allows for easy installation and reduced structural support requirements, making it an ideal solution for both new constructions and renovations. Additionally, moulded grating is resistant to corrosion, which means it can withstand harsh chemical environments typically found in industries like petrochemicals, wastewater treatment, and manufacturing.