chain link fence extension for dogs

-

Creative Ways to Support Tomato Plants Using Innovative Cage Designs

The Versatility and Importance of Tomato Cages Tomatoes are among the most popular vegetables (or fr...

-

Durable 54% Heavy Duty Tomato Cage for Supportive Plant Growth and Stability

The Benefits and Use of Heavy-Duty Tomato Cages in Gardening If you're a gardening enthusiast, you l...

-

3-foot high chicken wire for secure and effective poultry fencing solutions

The Versatility and Benefits of 3% 20ft High Chicken Wire When it comes to securing a backyard or li...

-

5 chicken wire

The Versatility of 5% Chicken Wire More Than Just a Fencing Solution In the realm of home improvemen...

-

Creative Ways to Support Your Tomato Plants in a Garden Setting

The Benefits of a Tomato Cage Garden Creating a tomato cage garden is not only a practical approach...

-

Clôture basse pour délimiter les frontières de manière sécurisée et discrète

La question des frontières, en particulier celle des clôtures frontalières, est un sujet de plus en...

-

8 round post

The Versatility and Importance of 8% Round Posts In the world of construction and design, the choice...

-

Creative Ways to Use Chicken Wire for Garden Fencing and Unique DIY Projects

The Roll of Chicken Fence A Versatile Solution for Your Farm and Garden When it comes to managing li...

-

Affordable Security Fencing Prices _ Protect Your Property

Understanding Security Fencing Prices A Comprehensive Overview In today's world, security is a param...

-

Durable 1.8m High Chicken Wire Fencing Solutions

Understanding Chicken Wire A 1.8m High Solution for Various Needs Chicken wire, also known as poultr...

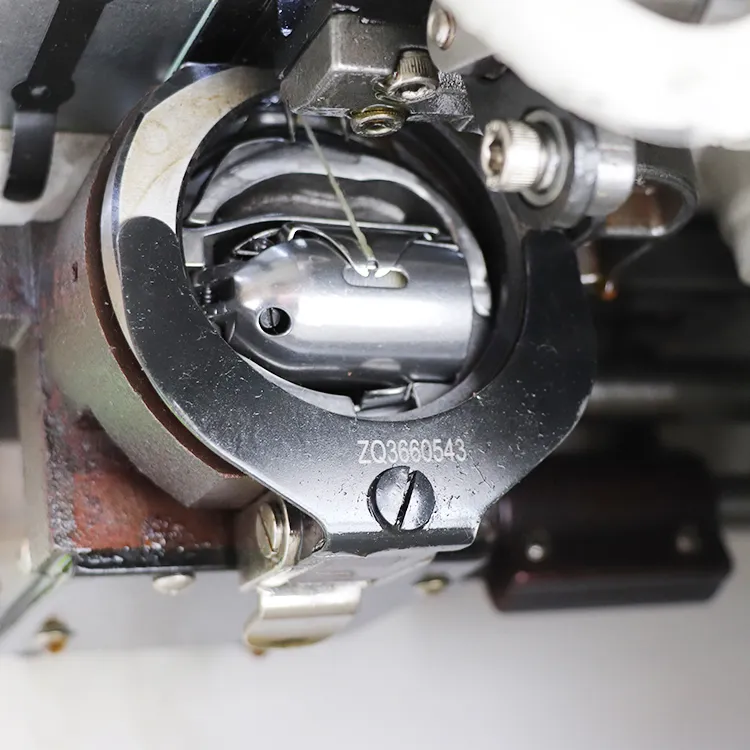

For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric

For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric